Completion of Commissioning

Note:

Operating with a lower heating flow temperature will

result in the appliance operating in the much more efficient

condensing mode. To ensure that the rooms are properly heated

the radiators must be sized accordingly.

Switch off the appliance.

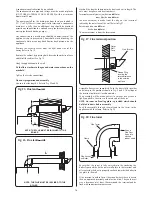

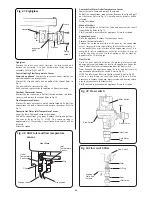

Disconnect the pressure gauge at the gas valve and tighten the

test point screw. Check for gas soundness around the screw. See

Fig. 18.

Refit the front cabinet.

If the appliance is to be passed over to the user immediately

then refer to Section 14.

If there is any possibility of the appliance being left inoperative

for very long periods in very frosty weather then drain the

appliance and the system. Turn off the gas and electricity

supplies.

Instruct the user in the efficient and safe operation of the

appliance and hand over the user’s leaflet.

Describe the operation and function of the controls. Set the

appliance and external controls to the user’s requirements.

Show the user how to vent the radiators.

Tell the user of the system pressure which must be maintained.

Tell the user what to do if the appliance is not to be used in frosty

conditions.

Advise the user of the importance of regular (annual) servicing to

maintain the efficiency and extend the life of the appliance.

Worcester Heat Systems will be pleased to offer a service

contract.

It is the law that any service work is carried-out by competent

engineers such as British Gas or CORGI registered engineers.

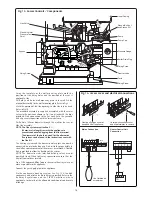

Pre-Service Inspection

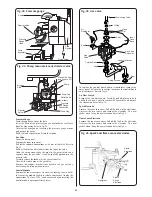

Check that the flue terminal (and terminal guard) are clear and

undamaged.

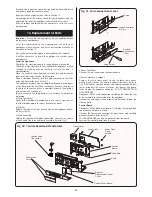

If the appliance is in a cupboard/compartment check that the

specified service spaces are clear. Refer to Fig.2 and 3.

Check the connections in the system and remake any which

show signs of leakage. Refill, vent and repressurise the system

after this work. Do not forget to refill the condensate trap and

syphon.

Operate the appliance and system and take note of any action

which needs to be taken.

NOTE: If the mains elecricity is turned off then the siphon

check procedure will take place when it is re-established.

Refer to Section 13 Commissioning.

To disable the siphon check procedure follow the following

instructions.

The siphon check programme will run automatically if:

a)

Power is applied or re-applied to the boiler.

b)

The boiler has not run for a period of 48 hours.

c)

At a change from Summer to Winter operation and

vice versa.

The siphon check is operating when there is

on the display.

The check comprises operation for 15 minutes at minimum rate.

To Disable the Siphon Check:

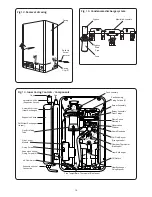

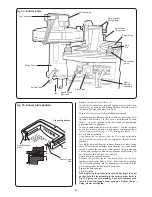

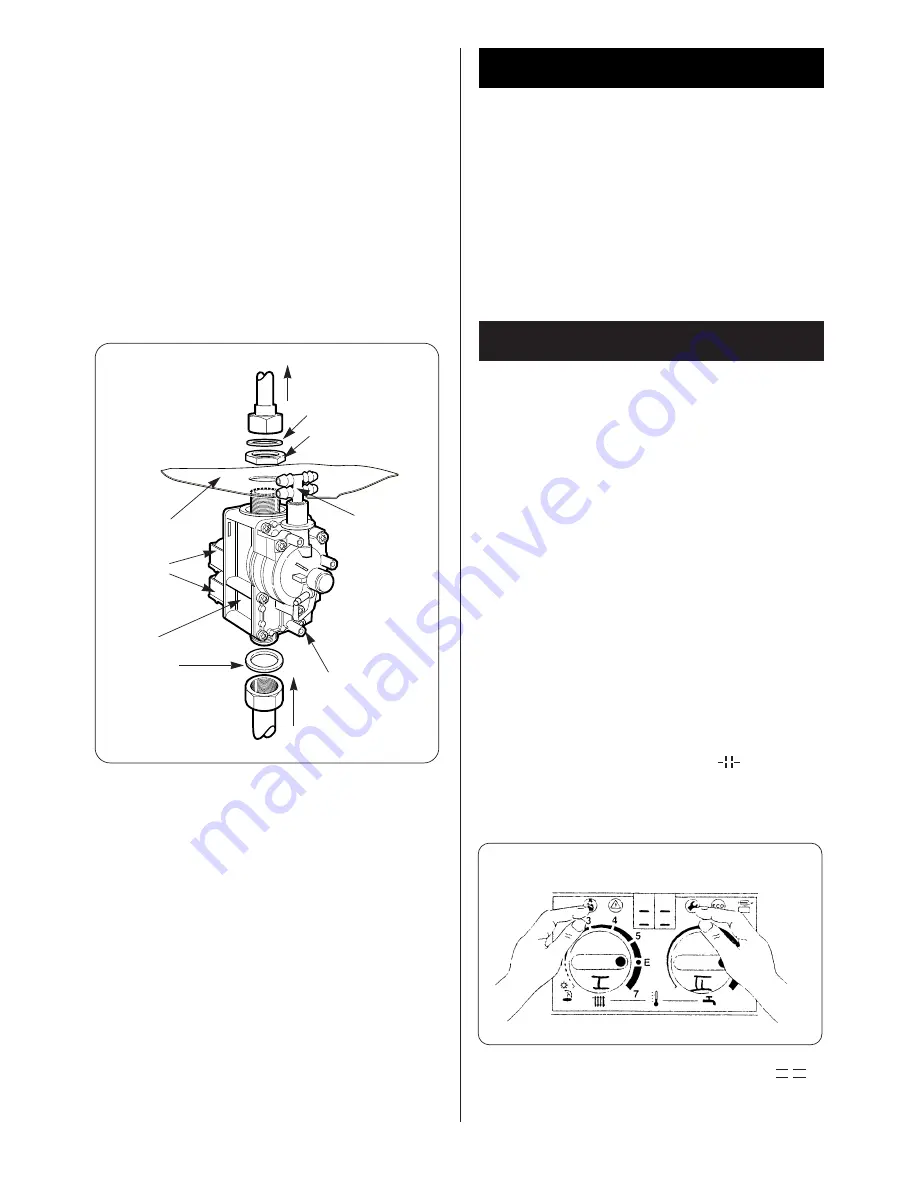

1. Set the CH temperature control to E. Refer to Fig.S1.

2. Press the Setting and Service buttons and hold until

appears on the display. Refer to Fig.S1.

15. Inspection and Servicing

14. Instructions For The User

21

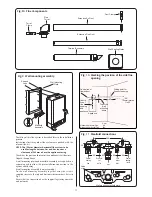

Fig. 18. Gas valve.

Inlet Pressure

Test Point

Seal

Locknut

Air

Distributor

Seal

Gas

Valve

Gas Valve

Solenoids

Inner Case

Base

Fig. S1..

Summary of Contents for Greenstar ZWBR 11-25 A31

Page 31: ...31 ...