English |

11

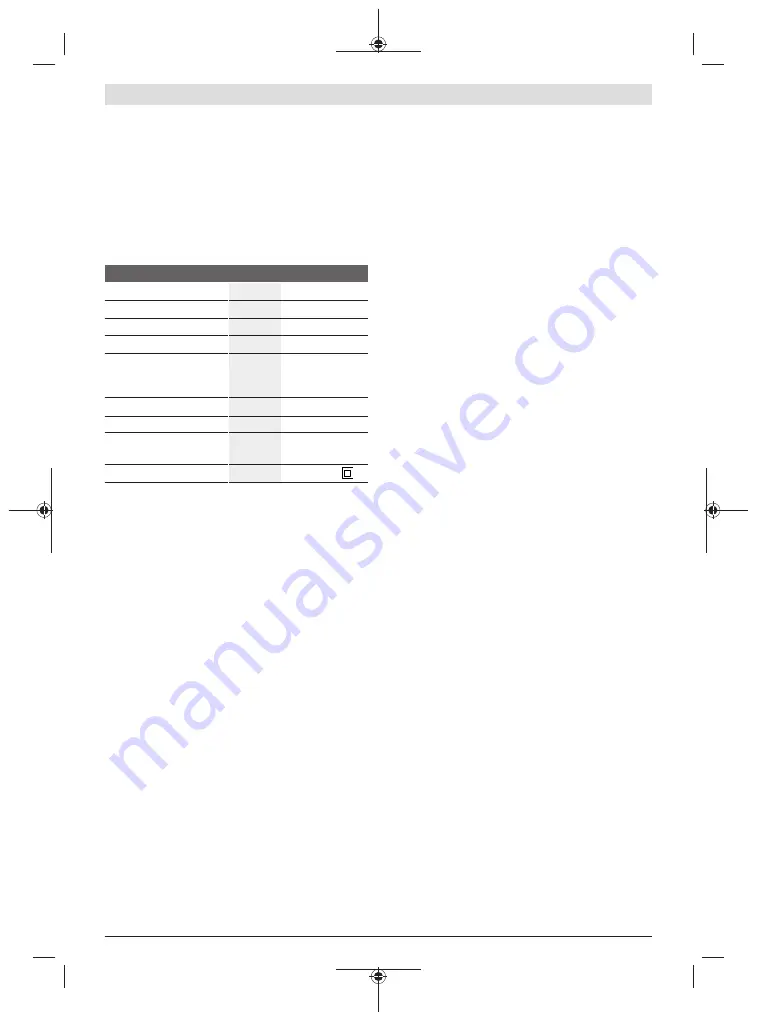

(1)

Dust protection cap

(2)

Locking sleeve

(3)

Chisel adjustment ring (Vario-Lock)

(4)

Lock-on button for on/off switch

(5)

On/off switch

(6)

Handle (insulated gripping surface)

(7)

Auxiliary handle (insulated gripping surface)

Technical Data

Demolition hammer

GSH 500

Article number

3 611 C38 7..

Rated power input

W

1100

Impact rate

min

-1

2900

Chisel positions

12

Impact energy per stroke

according to EPTA-Proced-

ure 05:2016

J

7.5

Tool holder

SDS-max

Lubrication

Grease lubrication

Weight according to EPTA-

Procedure 01:2014

kg

5.7

Protection class

/ II

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Noise/Vibration Information

Noise emission values determined according to

EN IEC 62841-2-6

.

Typically, the A-weighted noise level of the power tool is:

Sound pressure level

95

dB(A); sound power level

102

dB(A). Uncertainty K=

3

dB.

Wear hearing protection

Vibration total values a

h

(triax vector sum) and uncertainty K

determined according to

EN IEC 62841-2-6

:

Chiselling: a

h

=

15.5

m/s

2

, K =

1.5

m/s

2

The vibration level and noise emission value given in these

instructions have been measured in accordance with a

standardised measuring procedure and may be used to com-

pare power tools. They may also be used for a preliminary

estimation of vibration and noise emissions.

The stated vibration level and noise emission value repres-

ent the main applications of the power tool. However, if the

power tool is used for other applications, with different ap-

plication tools or is poorly maintained, the vibration level

and noise emission value may differ. This may significantly

increase the vibration and noise emissions over the total

working period.

To estimate vibration and noise emissions accurately, the

times when the tool is switched off or when it is running but

not actually being used should also be taken into account.

This may significantly reduce vibration and noise emissions

over the total working period.

Implement additional safety measures to protect the oper-

ator from the effects of vibration, such as servicing the

power tool and application tools, keeping their hands warm,

and organising workflows correctly.

Assembly

u

Pull the plug out of the socket before carrying out any

work on the power tool.

Auxiliary Handle

u

Do not operate your power tool without the auxiliary

handle

(7)

.

You can swivel the auxiliary handle

(7)

to any angle for a safe

work posture that minimises fatigue.

– Turn the lower gripping end of the auxiliary handle

(7)

an-

ticlockwise and swivel the auxiliary handle

(7)

into the re-

quired position. Then, turn the lower gripping end of the

auxiliary handle

(7)

clockwise to retighten.

Changing the Tool

With the SDS-max tool holder, you can change the applica-

tion tool simply and easily without additional aids.

The dust protection cap

(1)

largely prevents the penetration

of drilling dust into the tool holder during operation. When

inserting the tool, make sure that the dust protection cap

(1)

does not become damaged.

u

Replace a damaged dust protection cap immediately.

It is recommended that you have use an after-sales

service for this.

Inserting the application tool (see figure A)

– Clean and lightly grease the shank of the application tool.

– Push the locking sleeve

(2)

back and insert the applica-

tion tool by turning it into the tool holder. Release the

locking sleeve

(2)

to lock the application tool.

– Check the latching by pulling the tool.

Removing the application tool (see figure B)

– Push the locking sleeve

(2)

back and remove the applica-

tion tool.

Dust/Chip Extraction

Dust from materials such as lead-containing coatings, some

wood types, minerals and metal can be harmful to one’s

health. Touching or breathing-in the dust can cause allergic

reactions and/or lead to respiratory infections of the user or

bystanders.

Certain dust, such as oak or beech dust, is considered carci-

nogenic, especially in connection with wood-treatment ad-

ditives (chromate, wood preservative). Materials containing

asbestos may only be worked by specialists.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Bosch Power Tools

1 609 92A 77U | (25.01.2022)