6

| English

1

6

09 9

2

A 1WC | (9.8.1

6

)

Bosch Power Tools

Hammer Safety Warnings

Wear ear protectors.

Exposure to noise can cause hear-

ing loss.

Use auxiliary handle(s), if supplied with the tool.

Loss

of control can cause personal injury.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord.

Cutting ac-

cessory contacting a “live” wire

m

ay

m

ake exposed

m

etal

parts of the power tool “live” and could give the operator an

electric shock.

Use suitable detectors to determine if utility lines are

hidden in the work area or call the local utility company

for assistance.

Contact with electric lines can lead to fire

and electric shock. Da

m

aging a gas line can lead to explo-

sion. Penetrating a water line causes property da

m

age or

m

ay cause an electric shock.

When working with the machine, always hold it firmly

with both hands and provide for a secure stance.

The

power tool is guided

m

ore secure with both hands.

Secure the workpiece.

A workpiece cla

m

ped with cla

m

p-

ing devices or in a vice is held

m

ore secure than by hand.

Always wait until the machine has come to a complete

stop before placing it down.

The tool insert can ja

m

and

lead to loss of control over the power tool.

Products sold in GB only:

Your product is fitted with a

BS 13

6

3/A approved electric plug with internal fuse

(ASTA approved to BS 13

62

).

If the plug is not suitable for your socket outlets, it should

be cut off and an appropriate plug fitted in its place by an

authorised custo

m

er service agent. The replace

m

ent plug

should have the sa

m

e fuse rating as the original plug.

The severed plug

m

ust be disposed of to avoid a possible

shock hazard and should never be inserted into a

m

ains

socket elsewhere.

Products sold in AUS and NZ only:

Use a residual current

device (RCD) with a rated residual current of 30

m

A or

less.

Product Description and

Specifications

Read all safety warnings and all instruc-

tions.

Failure to follow the warnings and in-

structions

m

ay result in electric shock, fire

and/or serious injury.

Intended Use

The

m

achine is intended for chiselling work in concrete, brick,

m

asonry and asphalt as well as for driving in and co

m

pacting,

when using the respective accessories.

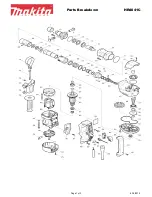

Product Features

The nu

m

bering of the product features refers to the illustra-

tion of the

m

achine on the graphics page.

1

Dust protection cap

2

Locking sleeve

3

Lock-on button for On/Off switch

4

On/Off switch

5

Handle (insulated gripping surface)

6

Auxiliary handle (insulated gripping surface)

Accessories shown or described are not part of the standard deliv-

ery scope of the product. A complete overview of accessories can

be found in our accessories program.

Technical Data

Assembly

Before any work on the machine itself, pull the mains

plug.

Auxiliary Handle

Operate your machine only with the auxiliary handle 6.

The auxiliary handle

6

can be set to any position for a secure

and low-fatigue working posture.

– Turn the botto

m

part of the auxiliary handle

6

in counter-

clockwise direction and swivel the auxiliary handle

6

to the

desired position. Then retighten the botto

m

part of the

auxiliary handle

6

by turning in clockwise direction.

Changing the Tool

The Hex tool holder allows for si

m

ple and convenient tool-free

changing of the application tool.

The dust protection cap

1

largely prevents the entry of drilling

dust into the tool holder during operation. When inserting the

tool, take care that the dust protection cap

1

is not da

m

aged.

A damaged dust protection cap should be changed im-

mediately. We recommend having this carried out by

an after-sales service.

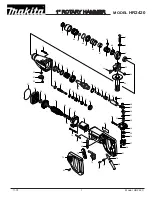

Inserting (see figure A)

– Clean and lightly grease the shank end of the tool.

– Push back the locking sleeve

2

and insert the tool in a twist-

ing

m

anner into the tool holder. Release the locking sleeve

2

again in order to lock the tool.

– Check the latching by pulling the tool.

Demolition Hammer

GSH 5X Plus

Article nu

m

ber

3

6

11 C38

2

..

Rated power input

W

10

2

5

I

m

pact rate

m

in

-1

2

750

I

m

pact energy per stroke

according to

EPTA-Procedure 05/

2

009

J

6

.8

Tool holder

17

mm

Hex

Lubrication

Grease lubrication

Weight according to

EPTA-Procedure 01:

2

014

kg

5.5

Protection class

/

II

The values given are valid for a no

m

inal voltage [U] of

2

30 V. For differ-

ent voltages and

m

odels for specific countries, these values can vary.

OBJ_BUCH-2320-002.book Page 6 Tuesday, August 9, 2016 11:00 AM