6 720 607 909

Installation instructions

11

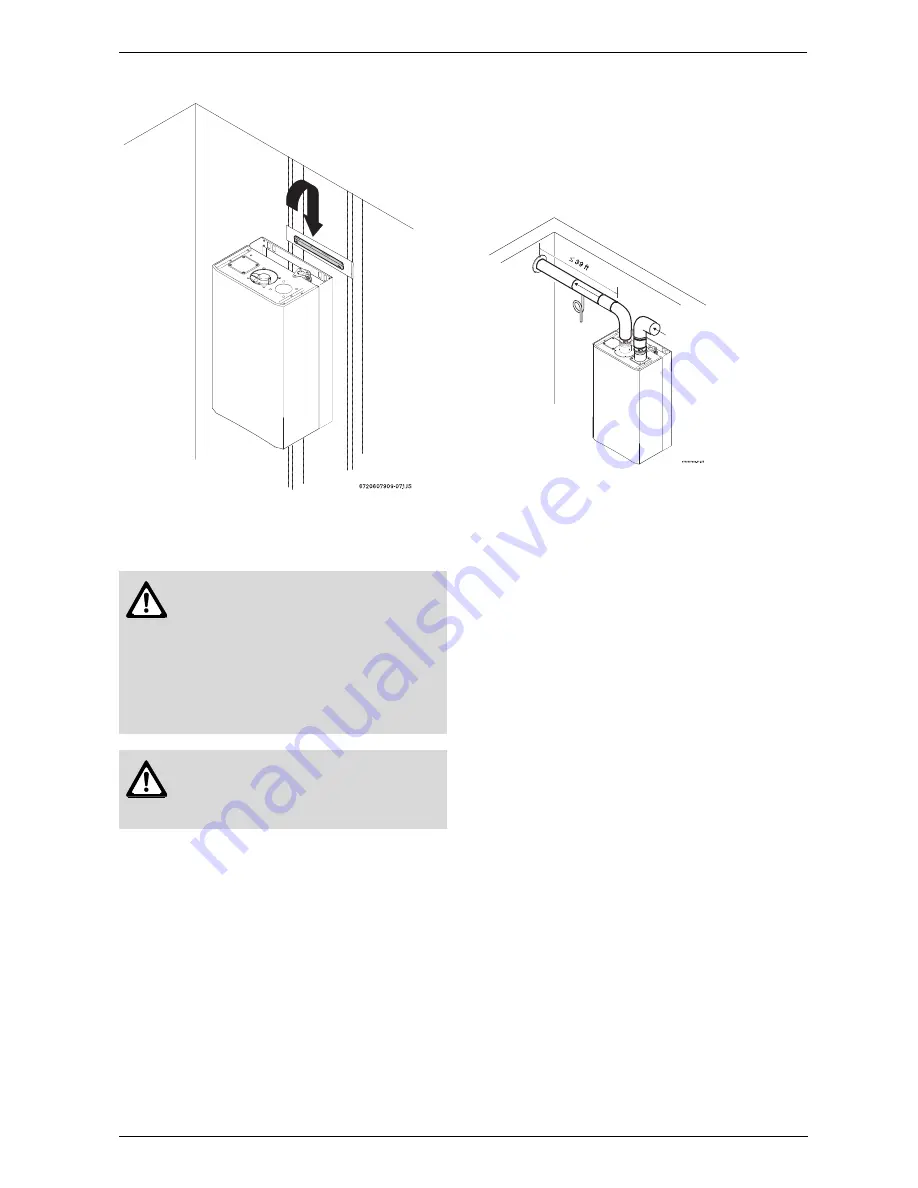

Fig. 10 Mounting the heater

3.5

Combustion air requirements

Twin pipe

The GWH-345/450-ESR is designed as a sealed

combustion appliance. It is recommended that the

combustion air be provided by a dedicated 3” pipe to

the outside. If terminating combustion air piping

horizontally, pitch vent down 1/4" per foot towards

termination to prevent rain from entering the appliance.

The combustion air pipe may be constructed of

aluminum flex, PVC or any other rigid or semi rigid

sealed pipe. The combustion air inlet must be located in

such a manner as to provide a minimum 3 foot

clearance from the exhaust vent terminator.

The maximum length of the combustion air inlet is 39

feet with one elbow. Subtract 6 feet for each additional

elbow. Maximum number of elbows permitted is 4.

Single pipe

Although it is permissible to draw combustion air from

inside the structure, it is not the manufacturer’s recom-

mended installation method. Always install a 3 inch

elbow on the combustion air inlet to prevent foreign

objects from falling into the unit (see Fig. 11).

Fig. 11

If a single pipe installation is performed. Use the follow-

ing guidelines when providing adequate combustion air

for the recirculating water heater as well as any other

appliances that may consume air in the space. Always

follow local codes if more stringent.

•

Appliances located in unconfined spaces:

–

a)

An unconfined space is one whose volume is

greater than 50 cubic feet (1.42 cubic meter) per

1000 Btu per hour (292.81 watts) of the

combined rating of all appliances installed in the

space. That would be 6200 cubic feet (175.6

cubic meter) of air required for the GWH-345/

450-ESR alone.

–

b)

In unconfined spaces in buildings of

conventional frame, masonry, or metal

construction, infiltration air is normally adequate to

provide air for combustion.

–

c)

Installations in structures that have been tightly

constructed (air infiltration rate of 0.40 ACH or

less) must provide combustion air per the National

Fuel Gas Code. Consult an HVAC specialist if

your air infiltration rate is questionable. For these

types of installations, the twin pipe system must be

used.

Warning:

In areas where freezing

temperatures are common the twin pipe

system is recommended. In a single

pipe installation, a negative air condition

may result in cold air being drawn

across the heat exchanger coil causing

it to freeze and burst.

This failure is

not covered under the

manufacturer’s warranty

.

Warning:

When installed in an

environment where corrosive chemicals

or dirty air are present the twin pipe

system is required.