Instructions for the installer

23

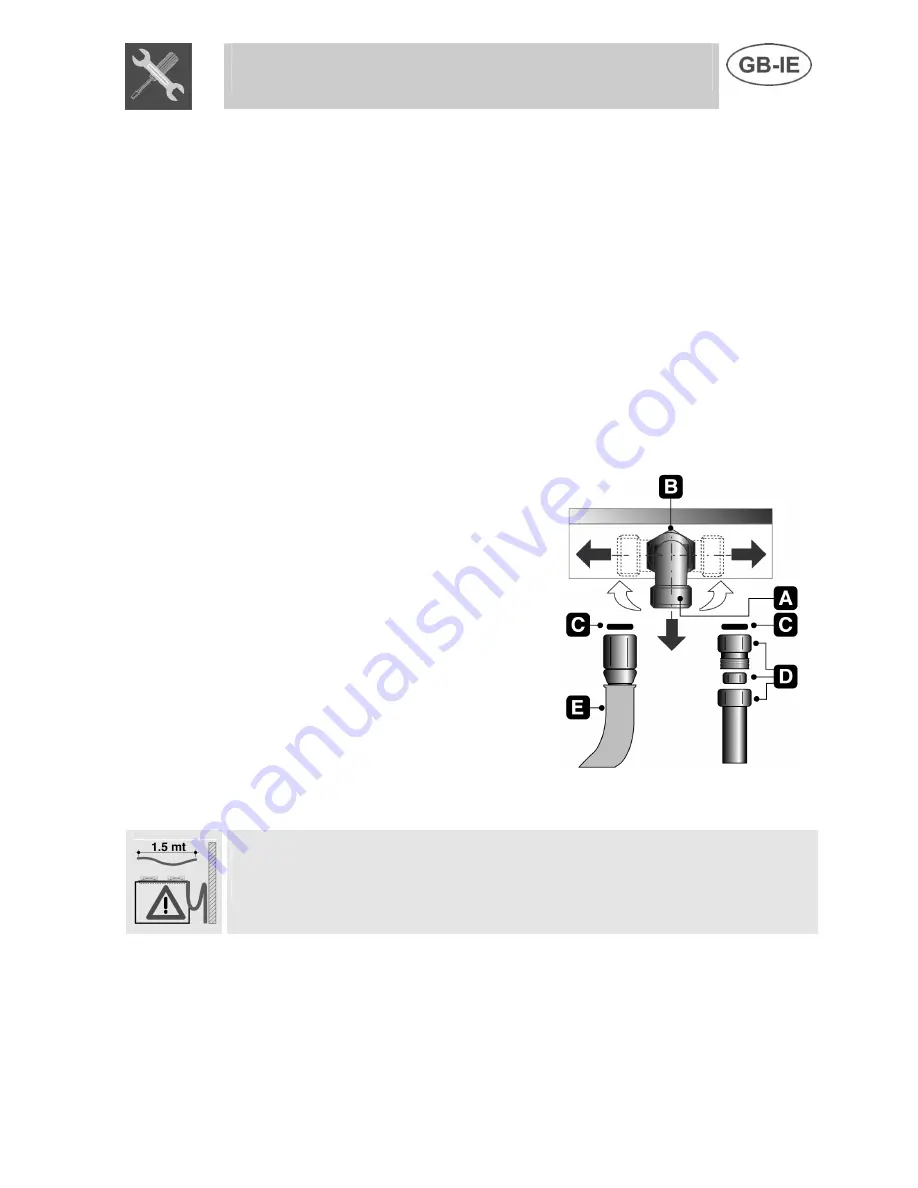

4. GAS CONNECTION

Connection to the gas mains may be made with a

rigid copper pipe

or

with a

flexible pipe

and conforming to the provisions defined by standard

regulations in force.

To facilitate connection, fitting

A

on the rear of the appliance may be

adjusted laterally. For this purpose, loosen hexagon nut

B

, turn fitting

A

to the desired position, and retighten hexagon nut

B

(tightness is ensured

by a biconical brass ring). Use a soapy solution to check for proper

tightness. Never use a free flame.

The hob has been inspected for

G20

(2H)

natural gas

at a pressure of

20 mbar. For use with other types of gases, see Section “5.

ADAPTATION TO DIFFERENT TYPES OF GAS”. The gas intake fitting

is ½” gas external threaded (ISO 228-1).

Connection with rigid copper pipe:

the connection to the gas mains must

not provoke stress of any kind on the

hob.

Connection may be made by using

biconical adapter

D

with insertion of

gasket

C

(supplied).

Connection with flexible pipe:

use

only flexible pipes conforming to

standard regulations in force, inserting

gasket

C

(supplied) between fitting

A

and flexible pipe

E

.

The flexible pipe has to be installed so that pipe length does not exceed

1.5 meters of maximum extension. Make sure that the pipes do not touch

any moving parts or become damaged.