en | 8 | User guide |

OBD 2220

Info Scan

580000 | REV. A | 04.2017

Bosch Automotive Service Solutions Inc.

3

Getting Started

3.1 Introduction

The scan tool was developed by experts in the automo-

tive service industry to help diagnose vehicles and assist

in troubleshooting procedures.

The scan tool monitors vehicle events and retrieves

codes from the vehicle’s control modules to help pin-

point problem areas.

All information, illustrations and specifications contained

in this manual are based on the latest information avail-

able from industry sources at the time of publication.

No warranty (expressed or implied) can be made for its

accuracy or completeness, nor is any responsibility

assumed by the manufacturer or anyone connected with

it for loss or damages suffered through reliance on any

information contained in this manual or misuse of

accompanying product. The manufacturer reserves the

right to make changes at any time to this manual or

accompanying product without obligation to notify any

person or organization of such changes.

3.2

Download Scanning Suite

1. Go to www.boschdiytools.com.au to download the

Scanning Suite PC application. Scanning Suite is

NOT required to operate the scan tool.

2. Install the downloaded Scanning Suite application

before connecting the scan tool to the PC.

To be able to use Scanning Suite the PC must meet

the following minimum requirements:

•

Microsoft Windows 7, 8, and 10

•

Adobe Acrobat Reader

•

Screen Resolution of 800 x 600

–

If screen resolution is 800 x 600, in Display

Properties, Settings Tab, set Font Size to

Small Fonts.

3. Use Scanning Suite to determine if any updates are avail-

able for your tool by clicking Check for Update button.

4. Check for updates to Use Scanning Suite by clicking

on the Check For Scanning Suite Update button. This

should be done before checking for Tool Updates.

You can also configure the Scanning Suite Frequency (SS

Frequency) to automatically check every xx minutes. The

default frequency is 7 days.

Refer to instructions provided on www.boschdiytools.

com.au for how to install Scanning Suite and Tool

updates.

3.3 OBDII

On-board diagnostics version II (OBDII) is a system that

the Society of Automotive Engineers (SAE) developed to

standardize automotive electronic diagnosis.

Beginning in 1996, most new vehicles sold in the United

States were fully OBDII compliant.

Technicians can now use the same tool to test any OBDII

compliant vehicle without special adapters. SAE estab-

lished guidelines that provide:

•

A universal OBDII data link connector, called the

DLC, with dedicated pin assignments.

•

A standard location for the DLC, visible under the

dash on driver’s side.

•

A standard list of diagnostic trouble codes (DTCs)

used by all manufacturers.

•

A standard list of parameter identification (PID) data

used by all manufacturers.

•

Ability for vehicle systems to record operating condi-

tions when a fault occurs.

•

Expanded diagnostic capabilities that records a

code whenever a condition occurs that affects

vehicle emissions.

•

Ability to clear stored codes from the vehicle’s

memory with a scan tool.

3.4

SAE Publications

SAE has published hundreds of pages of text defining a

standard communication protocol that establishes hard-

ware, software, and circuit parameters of OBDII sys-

tems. Unfortunately, vehicle manufacturers have differ-

ent interpretations of this standard communications

protocol. As a result, the generic OBDII communications

scheme varies, depending on the vehicle.

3.5

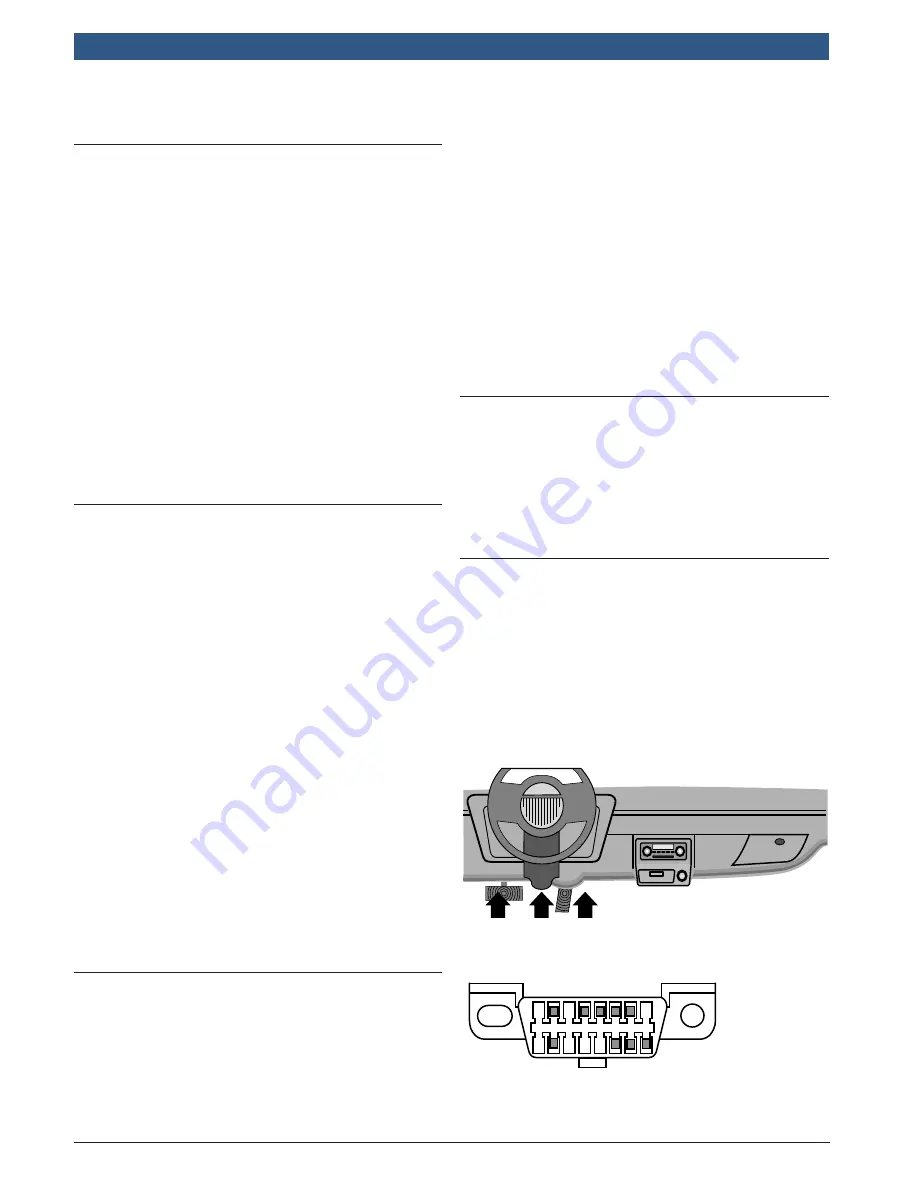

OBDII Data Link Connector (DLC)

The OBDII data link connector (DLC) allows the scan

tool to communicate with the vehicle’s computer(s).

Beginning in 1996, vehicles use the J1962 (OBDII) DLC,

a term taken from a physical and electrical specification

number assigned by the SAE (J1962). The DLC should

be located under the dashboard on the driver’s side of

the vehicle. If the DLC is not located under the dash-

board as stated, a decal describing its location should

be attached to the dashboard in the area the DLC should

have been located.

OBD II Data Link Connector (DLC) Pins

1 8

9 16

1. Manufacturer reserved

2. J1850 bus+

3. Manufacturer reserved