English–3

2 609 932 217 • (02.05) T

External Vacuuming (see Fig.

)

(Accessory pages)

Slide the extraction adapter

14

onto the outlet piece

8

and take care that the latching lever engages. For re-

moval, press the latching lever in at the rear and pull off

the extraction adapter.

When sanding vertical surfaces, hold the machine, so

that the extraction hose points downwards.

The vacuum cleaner must be suitable for the material

to be worked.

When vacuuming dry dust that is especially detrimen-

tal to health or carcinogenic, use a special vacuum

cleaner.

Ensure that the mains voltage is correct!

The voltage of the power source must agree with the

value given on the nameplate of the machine. Ma-

chines designated for 230 V can also be operated with

220 V.

Switching On/Off

To

switch on

the machine, press the On-Off switch

2

.

Lock

the depressed On-Off switch

2

by pressing the

lock-on button

3

.

To

switch off

the machine, release the On-Off switch

2

or push and then release it.

Preselect the required speed with the thumbwheel

1

(also while running) (PEX 250 AE/PEX 270 AE).

The required speed is dependent on the material and

can be determined by practical trials.

After longer periods of working at low speed, allow the

machine to cool by running for approx. 3 minutes at

maximum speed with no load.

■

Before any work on the machine itself, pull the

mains plug.

Sanding Plate Brake

An integrated sanding plate brake reduces the speed

when running at no load so that scoring is avoided

when placing the machine on the work piece.

A continuously increasing no-load speed over the

course of time indicates that the sanding plate brake is

worn and must be replaced by an authorized custom-

er service location for Bosch power tools.

Sanding Surfaces

Place the machine with the complete sanding sheet on

the surface to be worked.

Ensure uniform sanding pressure. Less sanding pres-

sure increases the sanding capacity and protects the

machine and the sanding tool.

The removal capacity and the sanding pattern are de-

termined mainly by the selection of the sanding sheet

(grain size), the speed of the sanding plate and the ap-

plication pressure.

Rough Sanding

Attach a sanding sheet with coarse grain (see

Applica-

tion Table

).

Apply only light sanding pressure to achieve increased

material removal.

Fine Sanding

Attach a sanding sheet with fine grain (see

Application

Table

).

With moderate pressure, move the machine in a circu-

lar pattern or alternately in lengthwise and crosswise

directions over the work piece.

Do not tilt the machine to avoid sanding through the

work piece (e.g. when sanding veneer).

After finishing the work, switch off the machine and lift

it from the work piece.

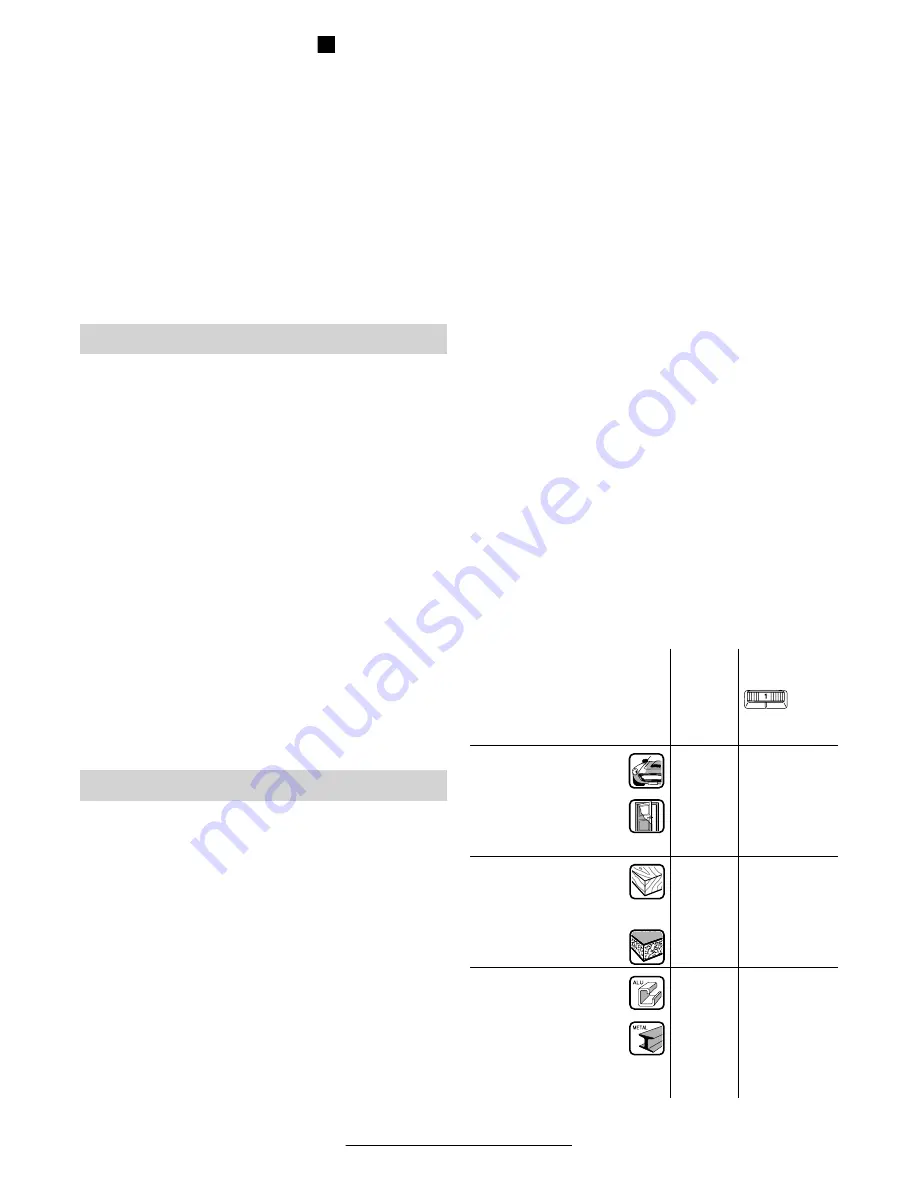

Application Table

The following table should be used only as a recom-

mendation.

The most suitable combination for the work to be per-

formed is best determined by practical trials.

Putting into Operation

Working Instructions

C

Material

Grain

Rough

sanding/

Fine

sanding

Thumbwheel

Position

(PEX 250 AE/

PEX 270 AE)

Paint

roughing

180/400

2–3

Paint touch-up

120/240

4–5

Paint removal

40/80

5

Softwood

60/240

5–6

Hardwood

60/180

5–6

Veneer

240/320

5

Aluminium

80/240

4–5

Steel

60/240

5

Rust removal from steel

40/120

6

Stainless steel

120/240

5