Connection

Installation continued

Electrical:

An electrical 10 amp socket needs to be within 1 m of the

hotplate to allow electrical connection. The socket must remain

accessible after installation of the appliance.

Important note:

Gas:

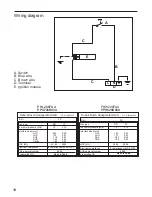

During the planning stage, consider the position of supply

The hob must be connected to the gas supply with upstream

connection of an isolation valve in accordance with the respec-

tively valid regulations. We recommend that the isolation valve

be fitted prior to the cooktop to enable isolation of cooktop

times.

To find out the factory set gas type, see bottom of cooktop next

to gas connection.

Remove plastic cap from gas supply line prior to installation.

1/2

Direction of gas flow is indicated on the rear of the regulator.

Use pipe compound or thread sealant, properly theaded pipes

and careful assembly procedure so that there is no cross

threading, etc., which might cause damage or leakage.

Make sure that all connections peformed are free of leakage.

In either of the cases, do not move or twist the L-tube from its

factory-set position.

If for some reason, the L-tube should be twisted, it is necessary

to make sure that this area is properly sealed. Make sure that

all connections performed are free of leakage.

The manufacture does not accept any liability for leakage on

connections performed by the installer or if the L-tube is moved

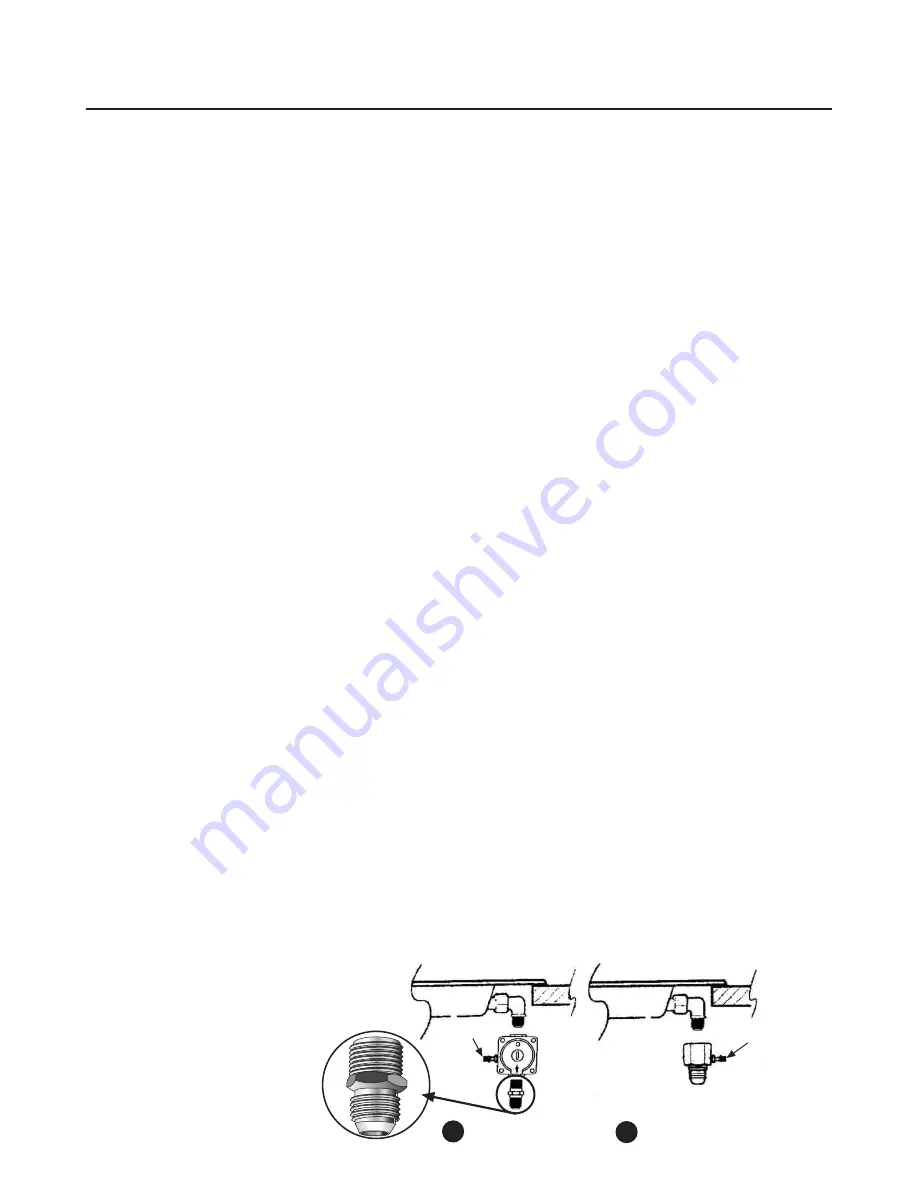

Natural gas connection

Pressure

test point

R

1

/

2

”

Pressure

test point.

5

R

1

/

2

”

For position of the inlet connection refer Fig.1-1a.

or twisted.

connections.

6

" connection as per Fig. 5. and Fig. 6.

from gas supply. The valve must be easily accessible at all

R

Fit regulator (N.G.) or a test point (Universal LPG) directly

to the

Universal LPG connection

This appliance is connected to the mains (240 VAC) by means

of the connecting lead which must be fixed to the kitchen unit

to prevent it from coming into contact with hot parts of the hob

(or an oven installed underneath) and remain accessible after

installation of the cooktop.

When making this connection make

sure that the lead cannot come into contact with hot parts

of the hob.

Important: This appliance must be earthed. When connecting

the cooktop ensure that the earth wire is connected first and

that all wires are connected to the correct terminals.

9