English |

15

External dust extraction (see figure C)

An extraction hose (dia. 35 mm)

(16)

(accessory) can be

connected to the chip ejector on either side (PHO 2000) or

a single side only (PHO 1500).

Connect the dust extraction hose

(16)

to a dust extractor

(accessory). You will find an overview of how to connect

various dust extractors at the end of these operating instruc-

tions.

The dust extractor must be suitable for the material being

worked.

When extracting dry dust that is especially detrimental to

health or carcinogenic, use a special dust extractor.

Self-generated dust extraction (see figure C)

A dust/chip bag (accessory)

(17)

can be used for smaller

jobs. Insert the sleeve of the dust/chip bag firmly into the

chip ejector

(1)

. Empty the dust/chip bag

(17)

at regular in-

tervals to maintain optimum dust collection.

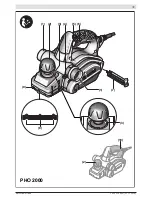

Selectable chip ejection (PHO 2000)

Using the changeover lever

(4)

, the chip ejector can be

(1)

adjusted to the right or left. Push the changeover lever

(4)

all

the way towards the end position until it clicks into place.

The selected chip ejector direction is indicated by an arrow

symbol on the changeover lever

(4)

.

Operation

Operating modes

Setting the cutting depth

Using the knob

(2)

, the cutting depth can be continuously

adjusted between 0–1.5 mm (PHO 1500) or 0–2.0 mm

(PHO 2000) with the aid of the cutting depth scale

(3)

(scale division = 0.25 mm).

Parking rest (see figure G)

The parking rest

(26)

makes it possible to put down the

power tool directly after working, without any danger of

damaging the workpiece or the planer blades. During the

work process, the parking rest

(26)

is raised and the rear

section of the planer base plate

(9)

is uncovered.

Note

: The parking rest

(26)

must not be removed.

Start-up

u

Pay attention to the mains voltage. The voltage of the

power source must match the voltage specified on the

rating plate of the power tool. Power tools marked

with 230 V can also be operated with 220 V.

u

Products that are only sold in AUS and NZ:

Use a resid-

ual current device (RCD) with a nominal residual current

of 30 mA or less.

Switching on/off

u

Make sure that you are able to press the On/Off switch

without releasing the handle.

To start the power tool, first press the lock-off switch

(5)

,

then press and hold the on/off switch

(6)

. To switch off the

power tool, release the on/off switch

(6)

.

Note:

For safety reasons, the on/off switch

(6)

cannot be

locked; it must remain pressed during the entire operation.

Practical advice

u

Pull the plug out of the socket before carrying out any

work on the power tool.

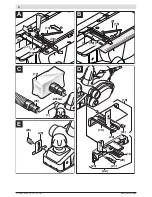

The service station in the case can be used as a mounting fix-

ture for the planer, e.g. for changing the blade.

u

Do not use the service station for stationary operation

of the planer.

Planing Procedure (see figure G)

Set the required cutting depth and position the power tool

with the front section of the planer base plate

(9)

on the

workpiece.

u

Only bring the power tool into contact with the work-

piece when switched on.

Otherwise there is danger of

kickback if the cutting tool jams in the workpiece.

Switch on the power tool and guide it over the surface of the

workpiece, applying uniform feed.

To achieve high-quality surfaces, apply only a low feed rate

and exert pressure on the middle of the planer base plate.

For the processing of hard materials, such as hardwood, and

also when utilising the maximum planing width, set only a

low cutting depth and reduce the planer feed as appropriate.

Excessive feed reduces the quality of the surface finish and

can lead to the chip ejector quickly becoming blocked.

Only sharp planer blades achieve good cutting performance

and make the power tool last longer.

The integrated parking rest

(26)

also enables a continuation

of the planing procedure following interruption at any point

on the workpiece:

– Place the power tool – with parking rest folded down –

onto the area of the workpiece that you will continue to

work on.

– Switch the power tool on.

– Shift the contact pressure onto the front of the planer

base plate and slowly slide the power tool forward (

➊

). In

doing so, the parking rest will swivel upwards and out of

the way (

➋

), meaning that the rear section of the planer

base plate is in contact with the workpiece again.

– Guide the power tool over the surface of the workpiece,

applying uniform feed (

➌

).

Chamfering edges (see figure H)

The V-grooves in the front of the planer base plate enable

quick and easy chamfering of workpiece edges. Select the V-

groove that corresponds to your chamfering width. Then po-

sition the planer with the V-groove onto the edge of the

workpiece and guide it along.

Groove used

Dimension a

(mm)

None

0–2.5

Small

1.0–4.5

Medium

2.0–5.0

Large

2.5–6.0

Bosch Power Tools

1 609 92A 49E | (12.11.2018)