8

| English

Technical data

Planer

PHO 2-82

Article number

3 603 B10 0..

Rated power input

W

710

Power output

W

400

No-load speed

min

-1

16000

Cutting depth

mm

0–2.0

Rebate depth

mm

0–7

Max. planing width

mm

82

Weight according to EPTA-Pro-

cedure 01:2014

kg

2.9

Protection class

/II

The specifications apply to a rated voltage [U] of 230 V. These spe-

cifications may vary at different voltages and in country-specific mod-

els.

Fitting

u

Pull the plug out of the socket before carrying out any

work on the power tool.

Choosing the Planer Blade

Always change both planer blades – replacing just one blade

will create an imbalance that could cause vibrations and

shorten the service life of the power tool.

Changing the HSS Planer Blades

u

Take care when changing the planer blade. Do not pick

up the planer blade by the cutting edges.

You may be

injured by the sharp cutting edges.

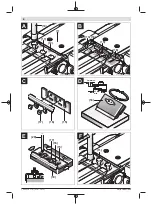

Removing the Planer Blades (see figures A–C)

– To replace the planer blades, turn the blade head

(13)

until the clamping jaw

(12)

is parallel with the planer base

plate

(1)

.

– Unscrew the three fastening screws

(11)

with the T-

handle socket spanner

(10)

and remove the clamping jaw

(12)

.

– Push the retaining clip

(16)

together with the planer

blade

(15)

out of the blade head

(13)

and/or the guide

groove

(14)

.

– Turn the blade head 180° and remove the second planer

blade.

Note:

Before changing or resharpening the planer blades,

remove the retaining clip

(16)

by undoing the fastening

screw

(17)

.

Resharpening HSS Planer Blades (see figure D)

Worn or blunt

HSS

planer blades can be resharpened using

the sharpening aid

(18)

(accessory) and a commercially

available grinding stone.

Place both planer blades in the sharpening aid and clamp

them firmly with the wing bolt. Make sure that both planer

blades are pushed in fully.

Move the planer blades placed in the sharpening aid steadily

across the grinding stone, applying light pressure.

Note:

The planer blades must not be resharpened by more

than 6 mm (i.e. to a minimum width of 23 mm). Both planer

blades must be replaced when they reach this size.

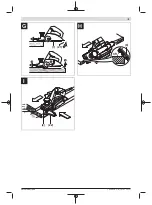

Fitting the Planer Blades (see figures E–F)

Before (re)inserting new or resharpened planer blades,

clean the blade head

(13)

and, if necessary, the planer

blade

(15)

and the retaining clip

(16)

. Clean heavily

gummed planer blades with spirits or petroleum.

Note:

New and resharpened planer blades must always be

set to the correct height before fitting.

The setting gauge

(19)

(accessory) is used to adjust the

height of the planer blades. Place the planer blade

(15)

and

the retaining clip

(16)

on the setting gauge. Make sure that

the blade retainer

(16)

engages in the groove intended for

this purpose. Press the planer blade

(15)

against the guide

and fix the retaining clip

(16)

in this position with the fasten-

ing screw

(17)

. This will automatically adjust the correct

height.

The planer blade must be fitted and aligned with the

centre

of the planer base plate

(1)

. Afterwards, tighten the three

fastening screws

(11)

with the T-handle socket spanner

(10)

.

Note:

Check that the fastening screws

(11)

are firmly

tightened before start-up. Turn the blade head

(13)

by hand

and ensure that the planer blades are not brushing against

anything.

Dust/Chip Extraction

The dust from materials such as lead paint, some types of

wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reac-

tions and/or cause respiratory illnesses in the user or in

people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials contain-

ing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u

Avoid dust accumulation at the workplace.

Dust can

easily ignite.

Clean the chip ejector

(5)

regularly. Clean a clogged chip

ejector using a suitable tool, e.g. a piece of wood, com-

pressed air, etc.

u

Do not allow the chip ejector to come into contact with

your hands.

You may be injured by rotating parts.

1 609 92A 57B | (02.07.2019)

Bosch Power Tools

Summary of Contents for PHO 2-82

Page 2: ...2 English Page 6 1 609 92A 57B 02 07 2019 Bosch Power Tools ...

Page 3: ... 3 PHO 2 82 1 2 3 4 5 6 7 3 9 8 Bosch Power Tools 1 609 92A 57B 02 07 2019 ...

Page 5: ... 5 45 8 2 m m m a x 9 mm max 1 G H I 21 22 2 8 Bosch Power Tools 1 609 92A 57B 02 07 2019 ...

Page 11: ... 11 1 619 PA2 313 Bosch Power Tools 1 609 92A 57B 02 07 2019 ...