English - 3

External Dust Extraction

The chip ejector 3 fits on both sides for direct con-

nection of the Bosch vacuum hose Ø – 35 mm 20

(accessory). When using other vacuum hose sys-

tems a suitable extraction adapter may be re-

quired.

The vacuum cleaner must be suitable for the ma-

terial to be worked.

When vacuuming dry dust that is especially detri-

mental to health or carcinogenic, use a special

vacuum cleaner.

Integrated Dust Extraction

A chip/dust bag 21 (accessory) can be used for

smaller jobs.

Empty the chip/dust bag regularly. Remove the

chip/dust bag, open the zipper and empty the

chip/dust bag.

Choice of Chip Ejector Side

(Right/Left)

The chip ejector 3 can be switched to the right or

left with the selector lever 7.

Always press the change lever until it engages in

the end position.

The selected ejector direction is marked with an

arrow.

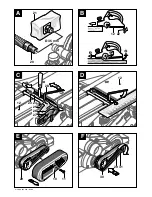

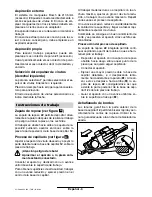

Park Rest (see figure

)

The park rest 22 allows the machine to be set

down directly after operation, without danger of

damaging the working surface or the planer

blade.

When planing, the park rest 22 is tilted upwards

thus enabling full contact of the rear part of the

planer base plate 12.

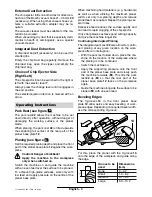

Planing (see figure

)

Set the required planing depth and place the front

part of the planer base plate 12 against the work-

piece.

Caution! Danger of kickback!

Apply the machine to the workpiece

only when switched on.

Switch the machine on and guide the machine

with an even feed over the surface to be planed.

To achieve high-grade surfaces, work only with

low feed and apply pressure on the centre of the

planer base plate.

When machining hard materials (e. g. hardwood)

as well as when utilising the maximum planer

width, set only low planing depths and reduce

planer feed, as required. Repeat the planing sev-

eral times.

Excessive feed reduces the surface quality and

can lead to rapid clogging of the chip ejector.

Only sharp blades achieve good cutting capacity

and give the machine longer life.

Continuing Interrupted Planing

The integrated park rest 22 also allows for contin-

ued planing at any given location on the work-

piece after an interruption:

– With the park rest folded down, place the ma-

chine on the location of the workpiece where

the planing is to be continued.

– Switch the machine on.

– Apply the supporting pressure onto the front

part of the planer base plate and slowly push

the machine forwards (

➊

). This tilts the park

rest 22 up (

➋

) so that the rear part of the

planer base plate 12 faces on the workpiece

again.

– Guide the machine alongside the surface to be

planed (

➌

) with an even feed.

Beveling Edges

The V-grooves 13 in the front planer base

plate 12 allow quick and easy beveling of work-

piece edges. Depending on required bevel width,

use the corresponding V-groove.

For this, place the planer with the V-groove 13

onto the edge of the workpiece and guide along

the edge.

Operating Instructions

B

B

Groove to be

used

Dimension a

(mm)

None

0 – 4.2

Small

1.9 – 6.2

Medium

4.7 – 8.9

Large

5.9 – 10.2

13

11 • 2 609 932 233 • TMS • 12.05.03