English |

17

❸

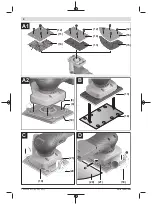

Position the sanding paper so that it fits tightly around

the sanding plate . Clamp the front part of the sanding

sheet under the front clamping bracket

(19)

. Ensure

that the sanding sheet

(18)

is not too short and that it is

correctly clamped. Swivel the sanding-sheet clamp

(20)

back into the starting position and lock it in place.

Unperforated sanding sheets, e.g. from rolls or bulk stock

sold by the metre, can be perforated using the punch

(26)

for the purpose of dust extraction. To do this, fit the sanding

sheet on the power tool and push the tool down onto the

punch (see figure

J

).

To remove the sanding sheet

(18)

, unlock both sanding-

sheet clamps

(20)

and pull the sanding sheet out of its

bracket.

Dust/Chip Extraction

The dust from materials such as lead paint, certain types of

wood and minerals can be harmful to human health. Touch-

ing or breathing in this dust can trigger allergic reactions

and/or cause respiratory illnesses in the user or in people in

the near vicinity.

Certain dusts, such as oak or beech dust, are classified as

carcinogenic, especially in conjunction with wood treatment

additives (chromate, wood preservative). Materials contain-

ing asbestos may only be machined by specialists.

– Use a dust extraction system that is suitable for the ma-

terial wherever possible.

– Provide good ventilation at the workplace.

– It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in

the country of use must be observed.

u

Avoid dust accumulation at the workplace.

Dust can

easily ignite.

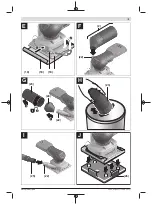

Self-generated dust extraction with dust bag

(see figures F–H)

Place and move the complete dust bag

(2)

onto the extrac-

tion outlet

(22)

until it lines up precisely with the power tool.

To empty the dust bag

(23)

, pull the complete dust bag

(2)

away from the extraction outlet

(22)

. Unscrew the adapter

(24)

from the dust bag

(23)

and empty the dust bag.

Note:

Empty the dust bag

(23)

in good time to ensure op-

timum dust extraction.

When working vertical surfaces, hold the power tool in such

a manner that the dust bag

(2)

faces downward.

External dust extraction (see figure I)

Fit a dust extraction hose

(25)

onto the extraction outlet

(22)

.

Connect the dust extraction hose

(25)

to an extractor. You

will find an overview of connecting to various dust extractors

at the end of these operating instructions.

The dust extractor must be suitable for the material being

worked.

When extracting dry dust that is especially detrimental to

health or carcinogenic, use a special dust extractor.

When working on vertical surfaces, hold the power tool with

the dust extraction hose facing downwards.

Operation

Starting Operation

Switching On/Off

u

Make sure that you are able to press the On/Off switch

without releasing the handle.

To

switch on

the power tool, press the on/off switch

(1)

.

To

switch off

the power tool, press the on/off switch

(1)

again.

Preselecting the orbital stroke rate

You can even preselect the orbital stroke rate during opera-

tion using the necessary orbital stroke rate preselection

thumbwheel

(5)

.

1–2

Low orbital stroke rate

3–4

Medium orbital stroke rate

5–6

High orbital stroke rate

The required orbital stroke rate is dependent on the material

and the work conditions and can be determined using prac-

tical tests.

The Constant Electronic keeps the orbital stroke rate at no

load and under load virtually consistent, guaranteeing uni-

form performance.

After working at a low orbital stoke rate for an extended

period, you should operate the power tool at the maximum

orbital stroke rate for approximately three minutes without

load to cool it down.

Temperature-dependent overload protection

In normal conditions of use, the power tool cannot be over-

loaded. If the power tool is overloaded or the permitted bat-

tery temperature is exceeded, the electronics of the power

tool will switch off until the temperature returns to within the

optimum operating temperature range.

Application Overview

Range of applications

Application

Abrasive

Speed setting

Sanding plate

80 x 130 mm

– Sanding surfaces and corner spaces

– Sanding rebates in windows and doors

– Sanding old paint and varnish

– Sanding wood

– Sanding solid wood edges and veneer edges

Coarse sanding

P40–P180

4–6

Fine sanding

P220–P400

1–3

Bosch Power Tools

1 609 92A 6LL | (23.06.2022)