16

| English

1 609 92A 0VJ | (10.11.14)

Bosch Power Tools

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suitable

for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the mate-

rials to be worked.

Prevent dust accumulation at the workplace.

Dusts can

easily ignite.

External Dust Extraction (see figure F)

– Insert a vacuum hose (diameter 19 mm; accessory) into

the vacuum connection

3

. Connect the vacuum hose to a

vacuum cleaner (accessory).

An overview for connecting to different vacuum cleaners can

be found at the end of these operating instructions.

The vacuum cleaner must be suitable for the material being

worked.

When vacuuming dry dust that is especially detrimental to

health or carcinogenic, use a special vacuum cleaner.

Operation

Before any work on the machine itself, pull the mains

plug.

When working with the machine, always hold it firmly

with both hands and provide for a secure stance.

The

power tool is guided more secure with both hands.

Starting Operation

Observe the mains voltage! The voltage of the power

source must correspond with the data on the type plate

of the machine.

Switching On and Off

– To

start

the machine, push the On/Off switch

6

forward so

that the

“1”

is indicated on the switch.

To save energy, only switch the power tool on when using

it.

– To

switch off

the machine, push the On/Off switch

6

to-

ward the rear so that the

“0”

is indicated on the switch.

Check sanding tools before using. The sanding tool

must be mounted properly and be able to move freely.

Carry out a test run for at least one minute with no load.

Do not use damaged, out-of-centre or vibrating sand-

ing tools.

Damaged sanding tools can burst and cause in-

juries.

Selecting the Sanding Tool

Choose the sanding tool according to the surface shape and

material you want to sand. Select an appropriate grit for the

desired material removal rate.

Working Advice

The material removal rate and surface quality are primarily de-

termined by the choice of sanding tool, the pre-selected

speed setting and the contact pressure.

Only immaculate sanding tools will deliver good sanding per-

formance and protect the power tool.

Use only original Bosch sanding accessories.

Preselecting the Speed

The required speed can be preselected with the thumbwheel

7

(also while running).

The required speed depends on the material and the working

conditions and can be determined through practical testing.

The data in the following table are recommended values.

After longer periods of working at low speed, allow the ma-

chine to cool down by running it for approx. 3 minutes at max-

imum speed with no load.

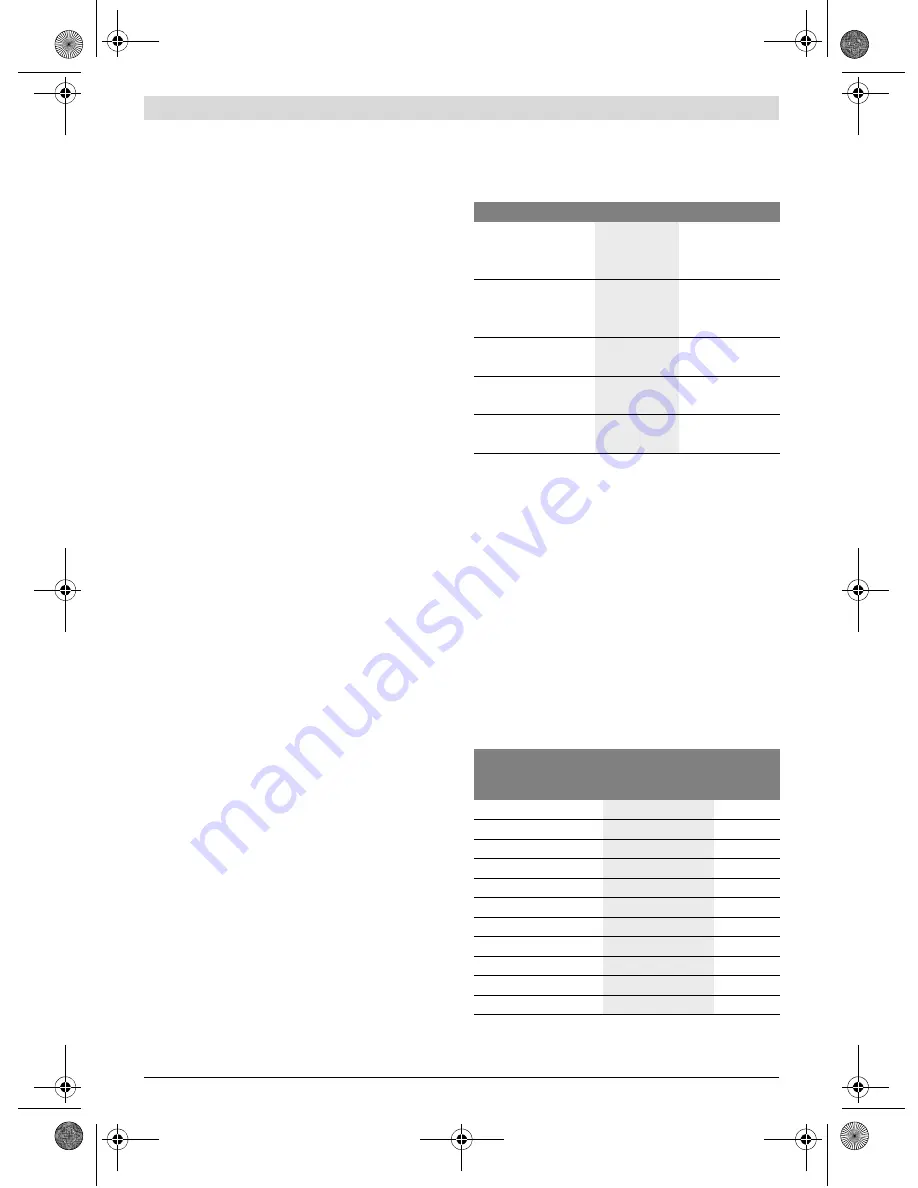

Sanding tool

Surface shape Grain size

Sanding sleeve

straight

flat

medium

fine

extra fine

80

120

240

Lamella roll (60 mm)

curved

uneven

medium

fine

extra fine

80

120

240

Lamella roll

(10 mm/5 mm)

grooved

medium

fine

80

120

Flexible sanding wheel

(60 mm/10 mm)

curved

flexible

medium

fine

80

120

Shank/sanding sleeve,

conical

medium

fine

80

120

1–2

low speed

3–4

medium speed

5–6

high speed

Application

Grain Size

(course sanding/

fine sanding)

Speed

setting

Roughening varnish

180/240

2/3

Touching up varnish

120/240

4/5

Removing varnish

40/60

5

Softwood

40/240

5/6

Hardwood

60/240

5/6

Veneer

180/240

2–4

Aluminium

80/240

4/5

Steel

40/240

5

Derusting steel

40/120

6

Stainless steel

80/240

5

Masonry, stone

80/240

5/6

OBJ_DOKU-33448-002.fm Page 16 Monday, November 10, 2014 10:59 AM