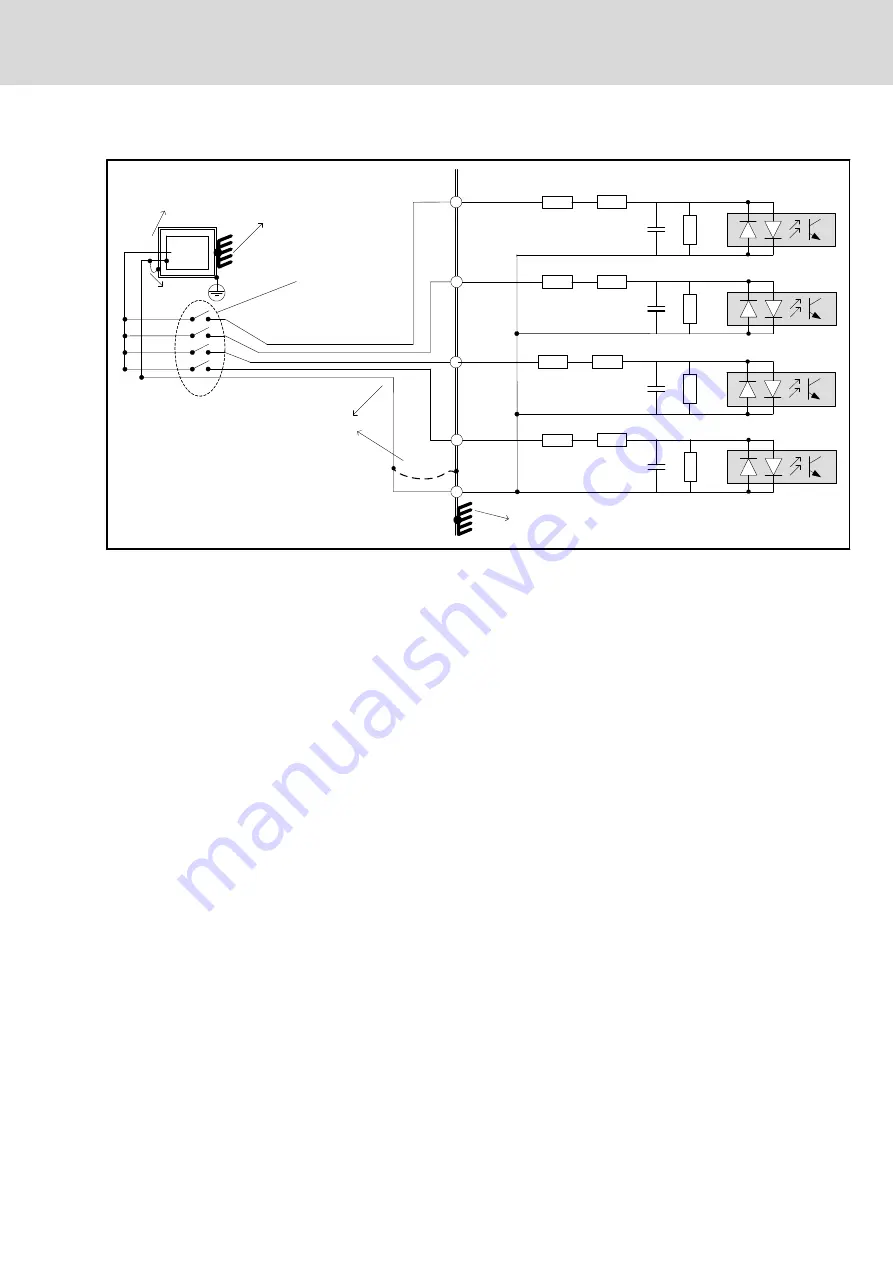

1 nF

1.1k

3.3k

TLP280

DigIn0

DigIn1

DigIn2

DigIn3

DigComm0

24 Volt

Power

supply

Bundle of geografical

“close” inputs with own

return current path

+

-

[See Note 3]

Application

Node

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

3.3k

1 nF

1.1k

1 nF

1.1k

1 nF

1.1k

TLP280

TLP280

TLP280

[See Note 1]

[See Note 2]

[See Note 4 about polarity]

[See Note 3]

Fig. 8-8:

First group of digital inputs

The second group (DigIn4 ... DigIn7 with DigComm1) is schematically

identical to the first group.

Notes

1. Follow the following cabling instructions:

●

Shielded cable is recommended, but not mandatory.

If shielded cable is used, the shielding on the NYCe 4000 side of

the cable must be connected to Shield (house connector).

Connect the other side to a convenient metal part or leave it

unconnected.

●

The digital I/O may be associated with more than one power

supply, and/or the cable may contain more than one minus for

power supply. If this is the case and if the cable is unshielded,

connect at least one of the minus wires of each power supply to

Shield (house connector).

2. Connect the minus of the I/O power to the housing and/or safety earth (if

this is not already the case).

3. Connect the NYCe 4000, a power supply or other equipment on a metal

frame or mounting base and make sure there is a galvanic contact.

4. Each group of 4 inputs can be used either as high side switching (HSS),

or as low side switching (LSS).

NYCe 4000 Multi-axis motion control system Hardware Sys‐

tem Manual

69/233

NY4120 and NY4120/10: PWM Drive Module

R911337671_Edition 18 Bosch Rexroth AG