3

Do not force tool. Use the correct tool for your

application.

The correct tool will do the job better and

safer at the rate for which it is designed.

Do not use tool if switch does not turn it “ON” or

“OFF.”

Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool.

Such preventive safety measures reduce

the risk of starting the tool accidentally.

Keep guards in place.

Maintain the guards in working order

and in proper adjustment and alignment.

Store idle tools out of reach of children and other

untrained persons.

Tools are dangerous in the hands of

untrained users.

Never leave tools running unattended.

Turn the power

OFF. DO NOT leave tool until it comes to a complete stop.

Maintain tools with care. Keep cutting tools sharp and

clean.

Properly maintained tools, with sharp cutting edges

are less likely to bind and are easier to control. Any

alteration or modification is a misuse and may result in

a dangerous condition.

Check for damaged guards or parts, misalignment or

binding of moving parts, breakage of parts, and any

other condition that may affect the tool’s operation.

If damaged, have the tool properly repaired or replaced

before using.

Many accidents are caused by poorly

maintained tools. Develop a periodic maintenance

schedule for your tool.

Use only accessories that are recommended by the

manufacturer for your model.

Accessories that may be

suitable for one tool may become hazardous when used

on another tool.

Service

Tool service must be performed only by qualified

repair personnel.

Service or maintenance performed by

unqualified personnel could result in a risk of injury. For

example: internal wires may be misplaced or pinched;

safety guard return springs may be improperly mounted.

When servicing a tool, use only identical replacement

parts.

Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock

or injury. Certain cleaning agents such as gasoline, carbon

tetrachloride, and ammonia may damage plastic parts.

Additional Safety Warnings for Router Tables

Read and understand table and router manual and

accessory warnings. Failure to follow all instructions

and warnings may result in serious personal injury.

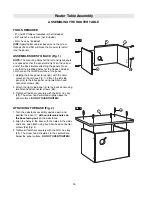

Fully assemble and tighten all fasteners required for

this table and for mounting the router to the plate.

Do not use the router table until all assembly and

installation steps have been completed. Check the

table and the router to make sure fasteners are still

tight before each use.

A loose table is unstable and

may shift in use.

Make certain the router is not plugged into a power out-

let when installing into the table, removing from table,

making adjustments or changing accessories.

Router

could accidentally start.

Do not plug router motor power cord into standard wall

outlet. It must be plugged into the router table switch.

Power tool switches and controls need to be within your

reach in emergency situations.

Before operating, make sure the entire unit (table with

router installed) is placed on and secured to a solid, flat,

level surface and will not tip. Use of auxiliary in-feed

and out-feed supports is necessary for long or wide

workpieces.

Long workpieces without adequate support

can flip off the table or cause the table to tip over.

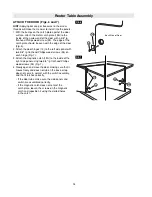

Be certain router motor is fully and securely clamped in

the router base. Periodically check the base fastener

clamping tightness.

Router motor can vibrate loose from

the base during use and fall from table.

Do not use the router table without the overhead guard

or auxiliary bit guard. Remove all dust, chips, and any

other foreign particles that can affect its function.

Adjust the guard height so that it clears the router bit

and the workpiece.

The guard will aid in keeping hands

from unintended contact with rotating bit.

Never place your fingers near a spinning bit or under

the guard when router is plugged in. Never hold the

workpiece on the out-feed side of bit.

Pressing the

workpiece against the out-feed side of the fence may

cause material binding and possible kickback pulling

hand back into bit.

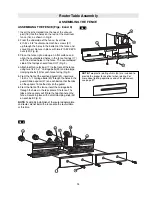

Guide workpiece by the fence to maintain control of

workpiece. Do not place material between router bit and

fence while routing the edge.

This placement will cause

the material to become wedged, making kickback possible.

Routers are intended for working with wood, woodlike

products and plastic or laminates, not for cutting or

shaping metals. Be sure workpiece does not contain

nails, etc

. Cutting nails may cause loss of control.

Do not use bits that have a cutting diameter that

exceeds the clearance hole in the tabletop insert.

Bit could contact insert ring, throwing fragments.

Install bit in accordance with instructions in router

manual and securely clamp the router bit in the collet

chuck before making any cuts

to avoid bit becoming loose

during operation.

Never use dull or damaged bits. Sharp bits must be

handled with care.

Damaged bits can snap during use.

Dull bits require more force to push the workpiece, possibly

causing the bit to break or the material to kick back.

The router table is designed to cut flat, straight and

squared materials. Do not cut material that is warped,

wobbly, or otherwise unstable. If the material is slightly

curved but otherwise stable, cut the material with the

concave side against the table or fence.

Cutting the

material with the concave side up or away from table may

cause the warped or wobbly material to roll and kick backm

causing user to lose control.

Never start the tool when the bit is engaged in the

material.

The bit cutting edge may grab the material,

causing loss of control of the workpiece.

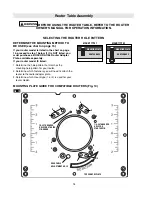

Feed the workpiece against the rotation of the bit. The

bit rotates counterclockwise as viewed from the top of

table.

Feeding the work in the wrong direction will cause the

workpiece to “climb” up on the bit, pulling the workpiece and

possibly your hands into the rotating bit.

Use push sticks, vertical and horizontally mounted

featherboards (spring sticks), and other jigs to hold

down the workpiece

. Push sticks, featherboards, and

jigs eliminate the need to hold the workpiece near the

spinning bit.

Summary of Contents for RA1171

Page 94: ...94 Notes Remarques Notas ...

Page 95: ...95 Notes Remarques Notas ...