3. Firmly connect the motor to the machine.

Fastening screws for foot assembly of IndraDyn A motors.

Motor

frame

size

Hole

⌀ [mm]

Screw 8.8

DIN EN ISO 4762

DIN EN ISO 4014

Tightening torque

M

A

[Nm] at μ

K

= 0.12

Washer DIN

EN ISO ...

100 ...

104

11

M10 x ...

48

28,738

130 ...

134

12

160 ...

164

14

M12 x ...

84

180 ...

184

14.5

200

19

M18 x ...

295

7,090

225

21

M20 × ...

415

Fig.6-2:

Fastening screws (foot mounting) tightening torque

4. Reattach the air baffles to the motor.

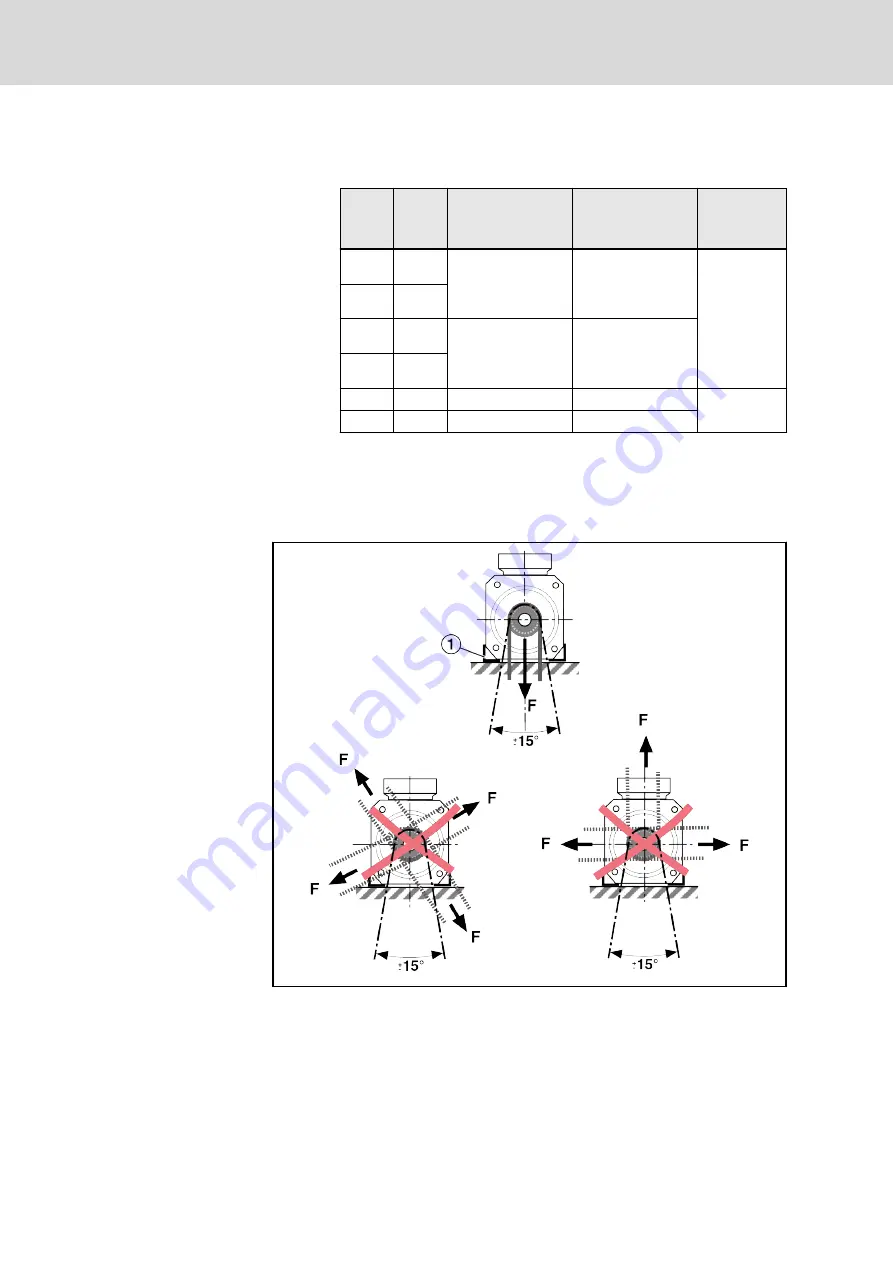

In contrast to flange assembly, radial forces may only be effective in a direc‐

tion perpendicular to the mounting surface (± 15°) if foot assembly is selec‐

ted. The transmission of forces in other effective directions is not allowed.

①

Mounting feet

Fig.6-3:

Example foot assembly

Bosch Rexroth AG

DOK-MOTOR*-2AD********-IT01-EN-P

Rexroth 2AD Asynchronous Housing Motors

32/61

Assembly

Courtesy

of

CMA/Flodyne/Hydradyne

▪

Motion

Control

▪

Hydraulic

▪

Pneumatic

▪

Electrical

▪

Mechanical

▪

(800)

426-5480

▪

www.cmafh.com