Troubleshooting and fault correction

61/64

RE 79039-01-B/01.2021, MOBILEX GFB 8000 series 40 general operating instructions,

Bosch Rexroth AG

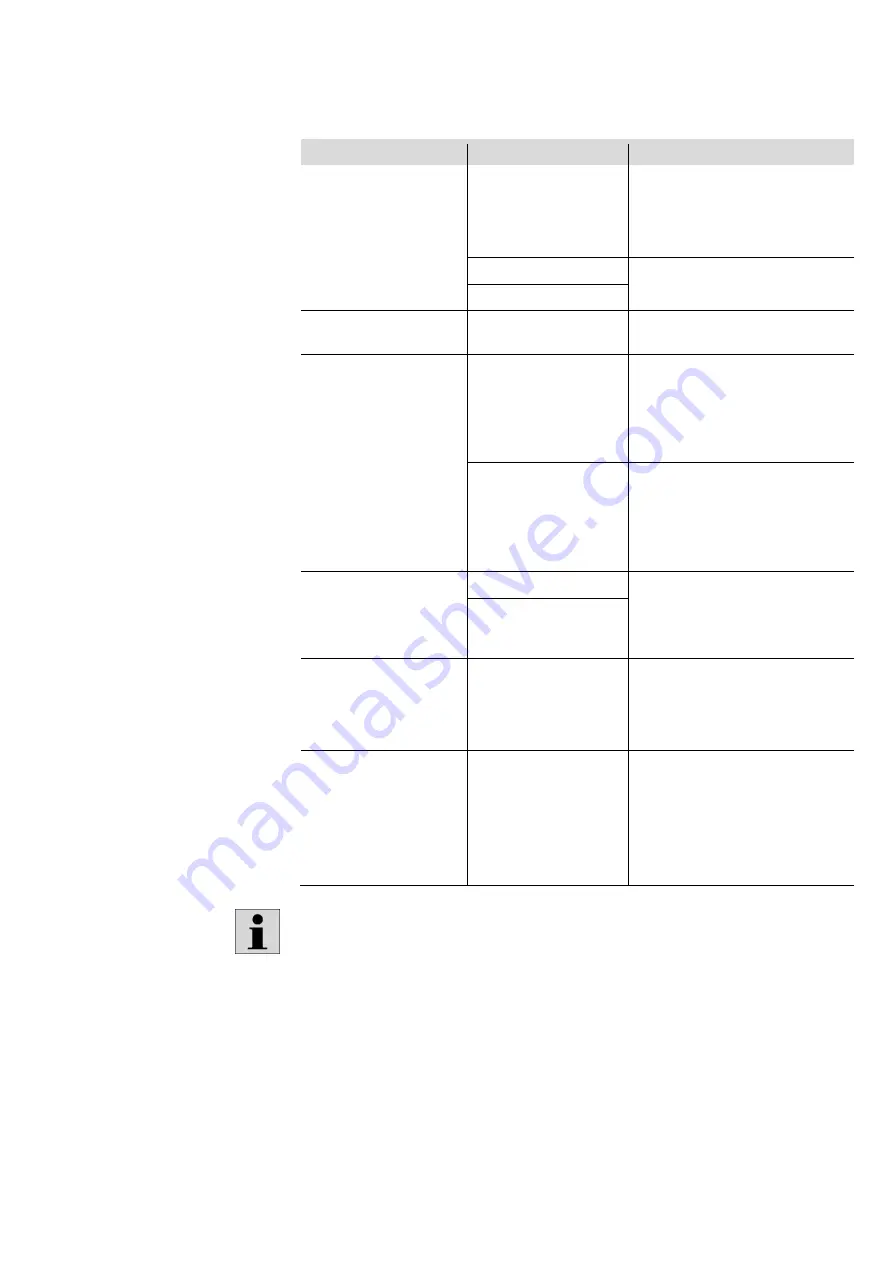

Table 7

Malfunction table of the MOBILEX GFB 8000

Malfunction

Possible cause

Remedy

Changed gearbox noises

Damaged gears

Notify Customer Service.

Check toothed components for

flaws such as pittings.

Let the damaged parts be replaced

by Rexroth Service.

Bearing play

Notify the Rexroth Service.

Bearing defective

Noises

Gearbox fastening has

become loose

Tighten screws with the required

tightening torque.

The operating

temperature is

substantially higher than

normal

The oil level is too high

or too low

Allow the planetary gearbox to cool

down to approx. 50 °C.

Check the oil filling level.

If required, fill with lubricating oil

or drain off lubricating oil if oil level

is too high.

The lubricating oil is too

old or badly

contaminated

Check in the operating instructions

of the system, machine or vehicle

when the last oil change took place,

if appropriate proceed to an oil

change. Proceed as described in

chapter 10.2 “Inspection”.

Leaking oil

Defective output seal.

Check seals as far as possible,

replace if necessary.

If the leak cannot be eliminated,

Rexroth Service must be notified.

Seals on partition seams

or on the locking screws

are defective

Lubricating oil is foaming Incompatibility of the

filled in lubricating oil

with the oil remains or

the preservation oil of

the planetary gearbox.

Replace the lubricating oil and rinse

with appropriate purging oil.

Decreasing or non-

existent brake action

Thermal overload of the

multiple-disk brake

Contact the Rexroth Service.

Let trained staff or Rexroth Service

employees carry out an inspection

on the multiple-disk brake. Replace

the disks, springs and sealing

elements.

If the malfunctions occurred cannot be eliminated, contact one of the contact

addresses indicated on

www.boschrexroth.com

or in the address directory in

appendix A “Address directory” of the material number-specific operating

instructions.