28/56 Installation

Bosch Rexroth AG

, A10VER Series 52, RE 91706-01-B/09.2015

▶

Make certain that the drain line and return line flow into the reservoir below the

minimum fluid level in all operating conditions. This prevents foaming.

▶

Make sure that the working environment at the installation site is fully free of dust

and foreign substances. The axial piston unit must be installed in clean condition.

Contamination of the hydraulic fluid can considerably affect the function and

service life of the axial piston unit and its suitability for use in explosive areas.

▶

Use lint-free cloths for cleaning.

▶

Use suitable mild cleaning agents to remove lubricants and other difficult-to-

remove contamination. Cleaning agents must not enter the hydraulic system.

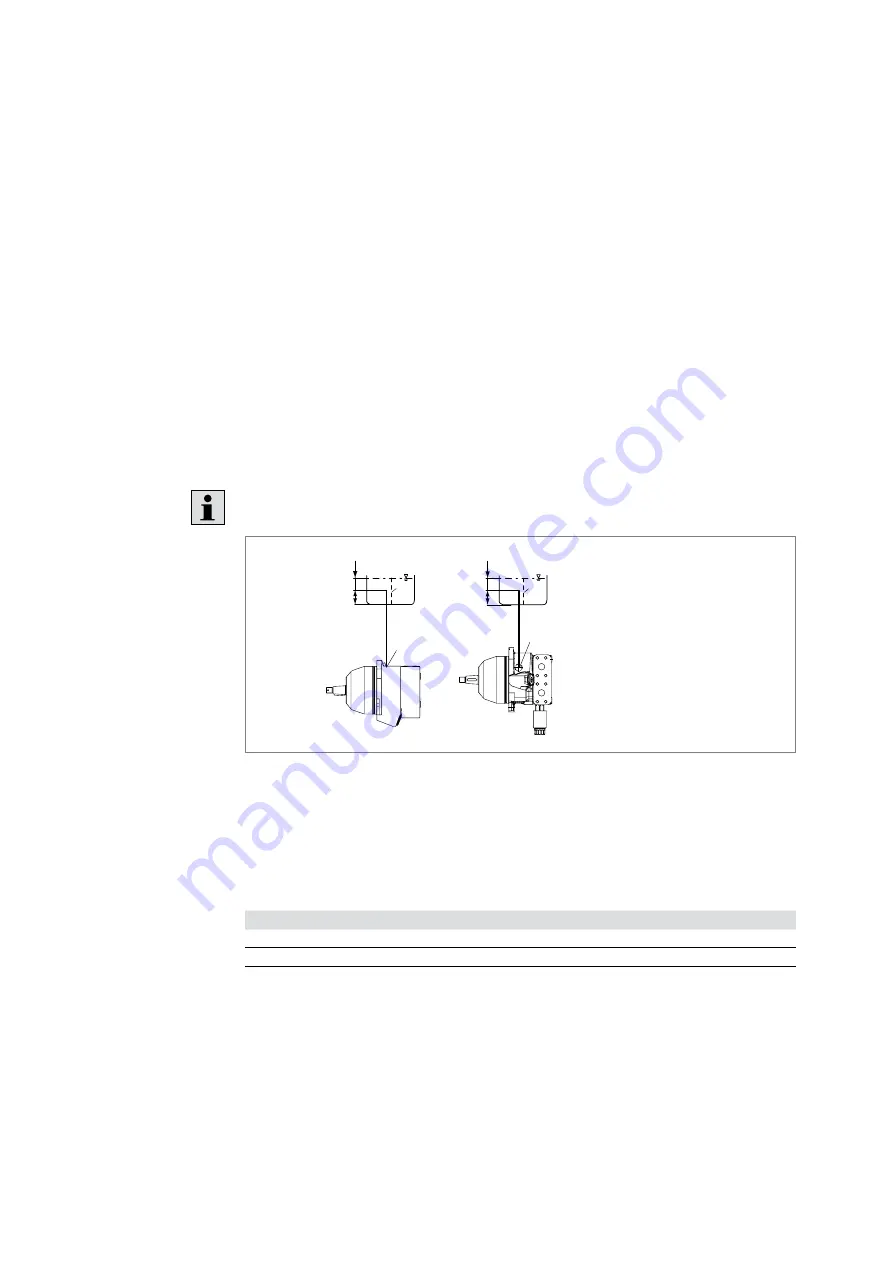

7.3 Installation position

The following installation positions are permissible. The piping layout shown

illustrates the basic layout.

7.3.1 Below-reservoir installation (standard)

Below-reservoir installation is when the axial piston unit is installed outside of the

reservoir and below the minimum fluid level.

Recommended installation position: 1.

L

h

t min

SB

h

min

L

h

t min

SB

h

min

1

2

Fig. 6: Below-reservoir installation A10VER with installation position 1–2

l

Highest drain port

h

min

Minimum required distance

to reservoir bottom (100 mm)

h

t min

Minimum required immersion depth

(200 mm)

Table 8: Below-reservoir installation

Installation position

Air bleeding

Filling

1 (drive shaft horizontal)

–

L

2 (drive shaft horizontal)

–

L