4.2

Technical data

4.2.1

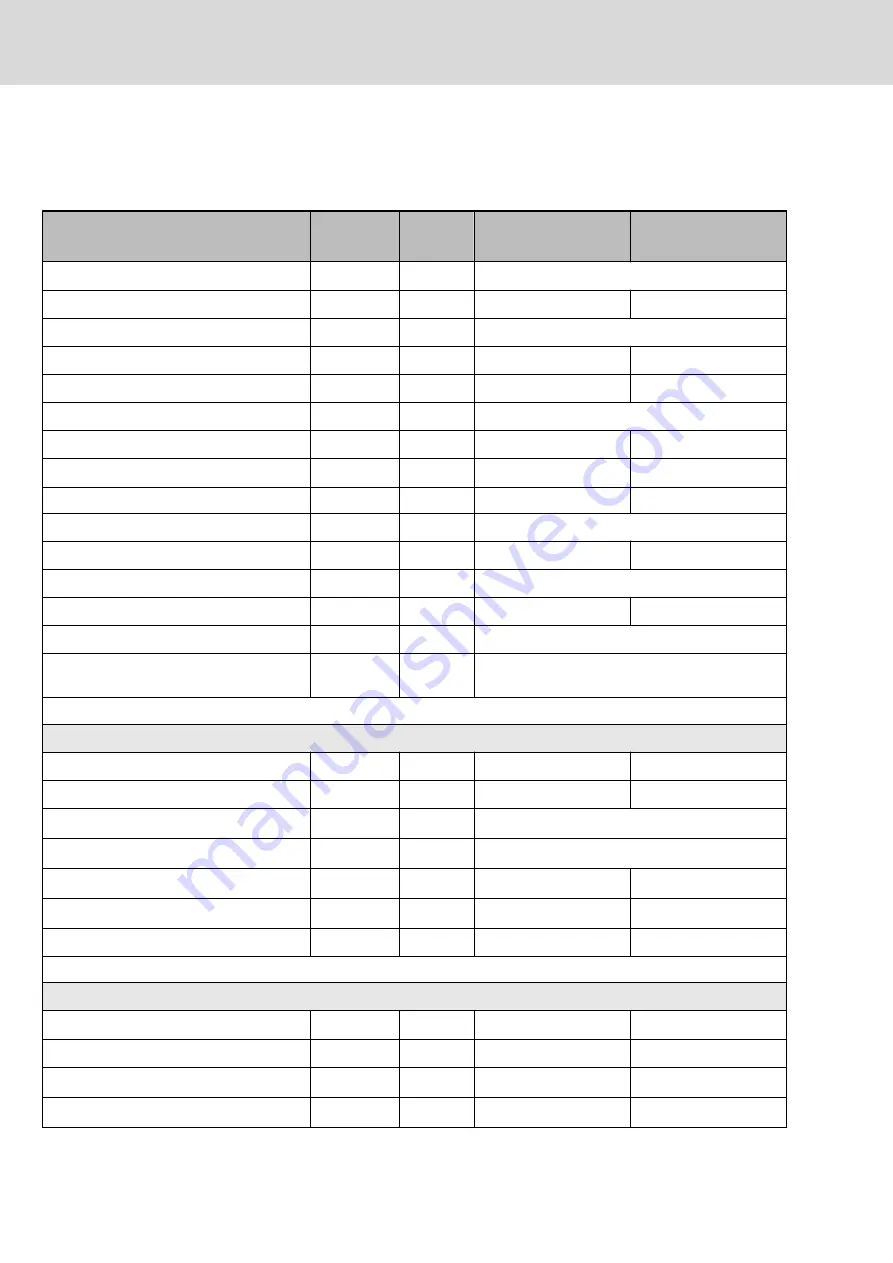

Data sheet BA1N16

Parameter

1)

Symbol

Unit

BA1N16-C3BHA

(forced ventilation)

BA1N16-C3BHL

(water cooling)

Maximum energy content

E

max

kJ

147.3

Rated power

3)

P

N

kW

42.5

32.0

Rated speed

n

N

min

-1

2000

Rated current

I

N

A

92.0

92.0

4)

Maximum current

I

max(rms)

A

196.5

290.7

Maximum speed

n

max

min

-1

6000

Thermal time constant

T

th

min

5.3

3.5

Leakage capacitance of the component

C

ab

nF

32.3

25.0

Number of pole pairs

p

--

2

3

Power wire cross-section

A

mm

2

25.0

Mass

m

mot

kg

300

290

Rotor inertia

J

rot

kg * m²

0.746

Sound pressure level

L

P

dB[A]

75 (+3)

72 (+3)

Ambient temperature during operation

T

um

°C

0 ... +40

Thermal

class

according

to

DIN EN 60034-1

I.CL.

-

155

Information on DC bus voltage 540 V

DC

Continuous power

3)

P

C

kW

42.5

32.0

Maximum power

3)

P

max

kW

90.2

122.4

Energy content for n

P

N

E

n

P

N

kJ

130.8

Speed range for energy content E

n

P

N

n

Range_P

N

min

-1

2000 ... 6000

Energy content for n

P

max

E

n

P

max

kJ

72.9

27.1

Speed range for energy content E

n

P

max

n

Range_P

max

min

-1

1770 ... 4580

1800 ... 3140

No-load losses

2)

at 4000 min

-1

P

V_4000

kW

2.83

3.05

Information on DC bus voltage 750 V

DC

Continuous power

3)

P

C

kW

48.5

43.1

Maximum power

3)

P

max

kW

126

151

Energy content for n

P

N

E

n

P

N

kJ

114.9

130.8

Speed range for energy content E

n

P

N

n

Range_P

N

min

-1

2810 ... 6000

2720 ... 6000

18/73

Technical data

BA1N Kinetic Energy Buffer

Bosch Rexroth AG R911393264_Edition 01

Summary of Contents for Rexroth BA1N

Page 1: ...BA1N Kinetic Energy Buffer Project Planning Manual R911393264 Edition 01 ...

Page 30: ...24 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 32: ...26 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 40: ...34 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 52: ...46 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 62: ...56 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 74: ...68 73 BA1N Kinetic Energy Buffer Bosch Rexroth AG R911393264_Edition 01 ...

Page 77: ...Notes BA1N Kinetic Energy Buffer 71 73 ...

Page 78: ...Notes 72 73 BA1N Kinetic Energy Buffer ...