Maintenance and repair

63/80

Hägglunds DOb, RE 15327-WA/05.2017, Installation and maintenance manual,

Bosch Rexroth AB

Scheduled maintenance

Planned maintenance at specific time intervals, including the following checks and

actions:

All points under frequent checks

Check all pressure levels

Check for stable temperature levels around the system

Drain water and sludge from the tank at the drain tap

Check the electric motor

Check the function of monitoring equipment/switches, etc

Cleaning.

NOTice

High pressure washing

Damage on equipment

▶

Never use a high pressure washing system to clean inside the drive unit

Check the cables

Check drain line flows and drain line oil condition

Check the hoses, couplings and pump(s), with respect to cracks, leakages and

condition

Check the shaft coupling through the inspection hole.

Check the air filter in the control unit

CAUTIoN

Rotating parts!

Risk of injury.

▶

Do not touch rotating parts.

Check that the panels of the drive unit not are damaged

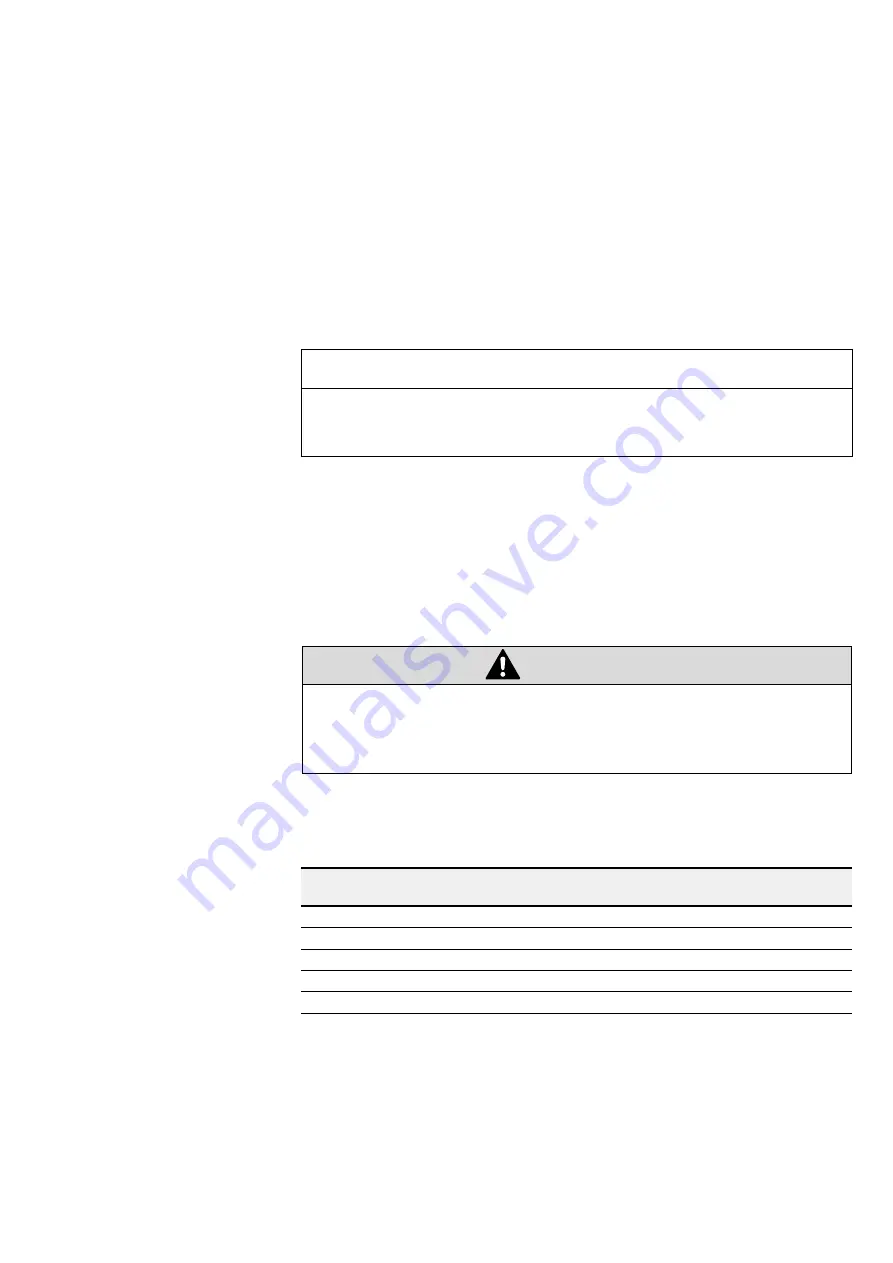

Table 11: Maintenace chart

Absolute max. intervals for major

inspection and replacement

Filter control

cabinet

Oil filters

Air breather

on tank

Hydraulic

fluid

After the first 100 working hours

-

R*

-

-

After 3 months or 500 working hours

-

R*

-

-

Once every 3 months

I

-

-

-

Once every 6 months

-

-

-

I

Once every 12 months

-

R*

R

-

I = Inspection

R = Replacement

*If the contamination indicator is tripped out, the filter must be changed immediately and the oil

examined.