power cables and power supply cables in opposite directions and preferably

in separate cable ducts.

Ideally, the motor power cables should exit the control cabinet at a distance

of at least d3 = 200 mm from the (filtered) power supply cable.

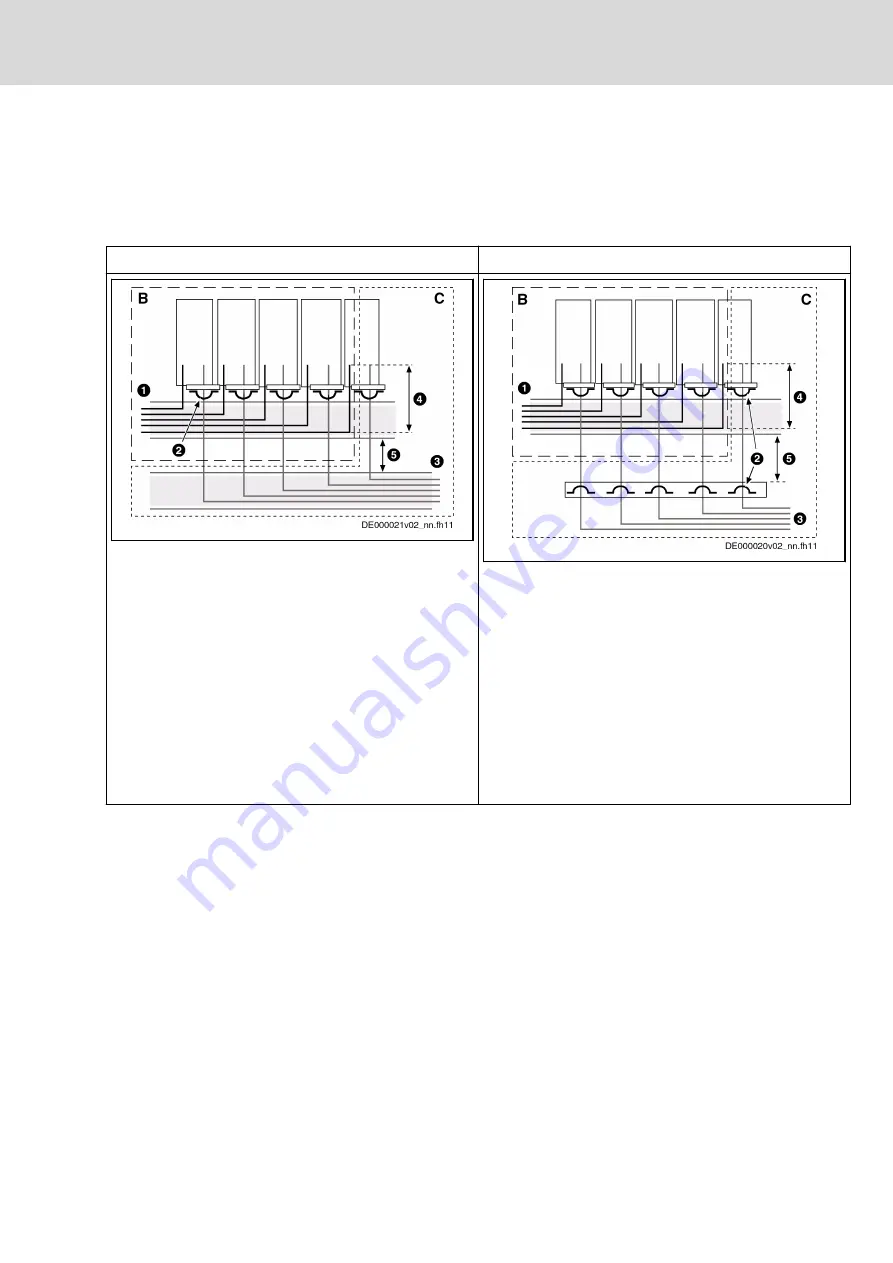

Converter - routing motor power cables

With cable duct

Without cable duct

B

Area B

C

Area C

1

Cable duct for mains connection lines

2

Shield connection of motor power cable with

clips at least at one point; alternatively, at

the device or control cabinet mounting plate

3

Cable duct for motor power cables

4

Parallel routing of mains connection lines

and motor power cables over a maximum of

300 mm

5

Distance of at least 100 mm or separated by

a grounded distance plate

Fig. 10-8:

Routing motor power cables with cable

duct

B

Area B

C

Area C

1

Cable duct for mains connection lines

2

Shield connection of motor power cable with

clips at least at one point; alternatively, at

the device or control cabinet mounting plate

3

Control cabinet outlet of motor power cables

4

Parallel routing of mains connection lines

and motor power cables over a maximum of

300 mm

5

Distance of at least 100 mm or separated by

a grounded distance plate

Fig. 10-9:

Routing motor power cables without cable

duct

Tab. 10-2:

Routing cables for converter

Ground connections

Housing and mounting plate

With the appropriate ground connections, it is possible to avoid the emission

of interference, because interference is discharged to ground on the shortest

possible way.

Ground connections of the metal housings of EMC-critical components (such

as filters, devices of the drive system, connection points of the cable shields,

devices with microprocessor and switching power supply units) have to be

well contacted over a large surface area. This also applies to all screw

connections between mounting plate and control cabinet wall and to

mounting a ground bar to the mounting plate.

The best solution is to use a zinc-coated mounting plate. Compared to a

varnished plate, the connections in this case have a good long-time stability.

Connecting elements

For varnished mounting plates, always use screw connections with tooth lock

washers and zinc-coated, tinned screws as connecting elements. At the

connection points, remove the varnish so that there is safe electrical contact

IndraDrive X Drive Controllers Power Sections XCS1, XMD1,

XMQ1

61/123

Mounting, dismounting and electrical installation

R911392532_Edition 01 Bosch Rexroth AG