9-40

Application Notes

Rexroth IndraDyn A

DOK-MOTOR*-MAD/MAF****-PR03-EN-P

9.18 Vibration Severity Level

IndraDyn A motors are dynamically balanced according to DIN ISO 2373.

Vibration severity step R is standard for all IndraDyn A motors. Steps S

and S1 are available for certain motors in case of special demands on the

mechanical running smoothness. Pay attention to the limitations in the

individual type codes.

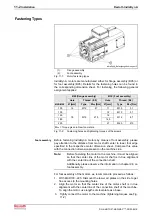

Effective vibration speed V

eff

in [mm/s]

MAD/MAF100...130

MAD/MAF160...180

Speed n [rpm]

Speed n [rpm]

Vibr

. sev. step

600-

1800

1800-

3600

3600-

6000

6000-

9000

9000-

12000

600-

1800

1800-

3600

3600-

6000

6000-

9000

R

0,71

1,12

1,8

2,8

4,5

1,8

1,8

2,8

4,5

S

0,45

0,71

1,12

1,8

2,8

0,71

1,12

1,8

1,8

S1

0,28

0,45

0,71

1,12

1,8

0,45

0,71

1,12

1,8

Fig. 9-52:

Effective vibration speed

The vibration behavior of attached or driven machine elements can cause

repercussions on the motor; in unfavorable cases, they can cause

premature deterioration or loss.

Due to the system-specific influences on the vibration behavior of the

system as a whole, the machine manufacturer must determine the

specific circumstances.

In certain cases, the machine elements may need to be balanced in such

a manner that no resonance or repercussions occur.

⇒

Already take the vibration behavior of the motor and the machine

elements into account when designing the system.

9.19 Explosion Protection

CAUTION

Danger of explosion! Invalidation of warranty!

⇒

The motor admitted for operation in hazardous areas

and labeled accordingly is merely a part of a drive

concept. Commissioning of the motors in such areas

may be carried out only with a control device that is

classified and permitted according to the conditions

of the areas subject to explosions.

⇒

It is imperative that you pay attention to the

information and notes in respect of project planning

for the selected control device for motor scavenging

already during project planning and before

commissioning the system.

Under certain preconditions, IndraDyn A motors are admitted for use in

hazardous areas. However, the ATEX motors (components for Group II,

Category 2G, ATEX guideline 94/9/EG, Appendix II, Section 2.2.1) may

only be used in certain defined environments. In this respect, please note

the required selection criteria in the type code of the respective motor, as

well as the additional information e.g. on selection, protection principle

and required labeling of the motors in chapter 13, “IndraDyn A for

Hazardous Areas”.

Summary of Contents for Rexroth IndraDyn A Series

Page 10: ...VIII Table of Contents Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 14: ...1 4 Introduction to the Product Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 150: ...5 42 Dimension Sheets IndraDyn A Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 174: ...6 24 Type Codes IndraDyn A Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 196: ...8 16 Connection Techniques Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 238: ...9 42 Application Notes Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 256: ...12 10 Operating IndraDyn A Motors Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 285: ...Rexroth IndraDyn A Index 14 5 DOK MOTOR MAD MAF PR03 EN P ...

Page 286: ...14 6 Index Rexroth IndraDyn A DOK MOTOR MAD MAF PR03 EN P ...

Page 287: ......