5-12

Operating Instructions

IndraDynA_ATEX

DOK-MOTOR*-IDYN*A*ATEX-IB02-D5-P

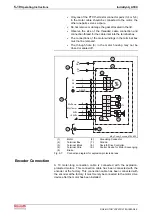

Protective conductor

terminal on motor size

Nominal

cross-section

Terminal area

100...130

4 mm²

4 mm² (finely stranded)

6 mm² (single-wire)

160...180

10 mm²

10 mm² (finely stranded)

10 mm² (single-wire)

Fig. 5-9:

Terminal for grounding conductor

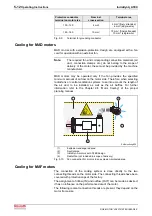

Cooling for MAD motors

MAD motors with explosion-protection design are equipped with a fan

cowl for operation with an external fan.

Note:

The required fan and corresponding connection materials (air

duct, connection clamps, etc.) do not belong to the scope of

delivery of the motor; these must be provided by the machine

manufacturer.

MAD motors may be operated only if the fan provides the specified

minimum amount of air flow on the motor side. Therefore, when selecting

radial fans or central ventilation systems, take into account the length of

the air duct to be installed, as well as the air baffles. For further

information refer to the Chapter 9.8 “Motor Cooling” of the project

planning manual.

1

4

3

2

Ex-Belueftung.EPS

(1):

Explosion-endangered area

(2):

Neutral area

(3):

IndraDyn A motors with ATEX design

(4):

Radial fan (not included in scope of delivery)

Fig. 5-10:

Fan connection for motors in an explosion-protected area

Cooling for MAF motors

The connection of the cooling system is done directly to the two

connecting threads on the motor side. The connecting threads have been

covered with protective caps at the factory.

The assignment of inflow (IN) and outflow (OUT) can be made as desired;

it has no influence on the performance data of the motor.

The following coolant connection threads are present, they depend on the

motor frame size.