25 / 74

MKE Synchronous Servomotors

Safety instructions on the product

Bosch Rexroth AG

R911402016, Edition 02

Type codes, meaning of the digits

5

Encoder

6

Shaft

7

Holding brake

8

Electrical connection

9

Housing design

10

Other designs (MKE037, -047, 098) / cable

gland (MKE118)

6

About this product

6.1

Safety instructions on the

product

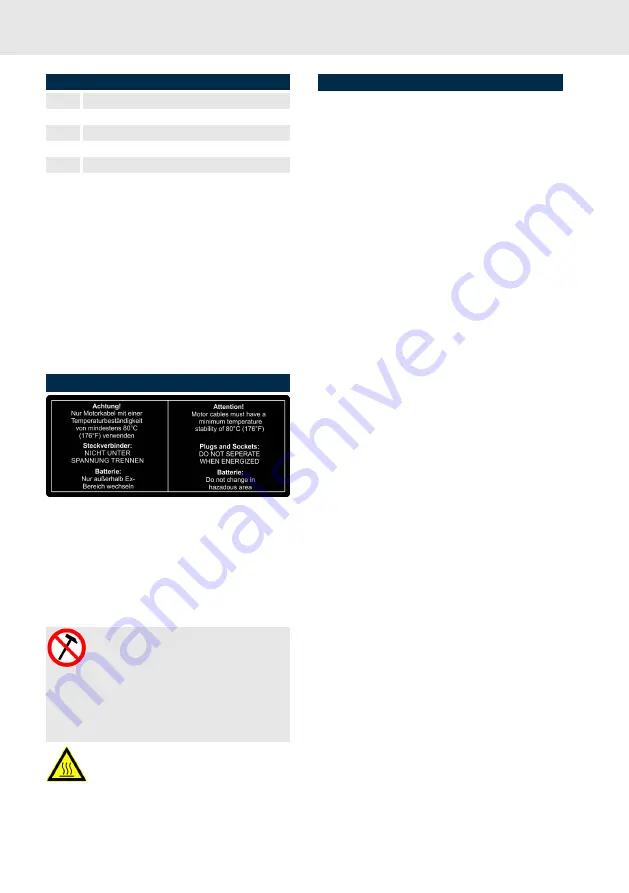

Please note the safety and prohibitive sign on the

motor. The sign significance is explained in the

following.

Information / meaning

Caution

Use motor cables with a thermal stability of at

least 80°C (176°F).

Plug connector

Never disconnect plug connectors under load

Battery

Change only outside of hazardous areas.

Motor damage due to strikes onto the motor

shaft

Do not strike the shaft end and do not exceed

the allowed axial and radial forces of the motor.

Hot surfaces with temperatures over 60

°C may

cause burns

Information / meaning

Let the motors cool down before working on the

motors or in close proximity to the motors. The

thermal time constant stated in the technical

data is a measure for the cooling time. Cooling

down can require up to 140 minutes.

- Wear safety gloves.

- Do not work on hot surfaces.