39 / 74

MKE Synchronous Servomotors

Assemble transmission elements

Bosch Rexroth AG

R911402016, Edition 02

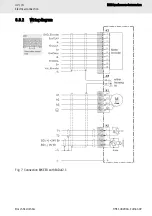

Table 15: Permissible shock load for MKE motors

Frame size

Maximum allowed shock load

(11

ms)

Axial

Radial

MKE037

10 m/s²

1000 m/s²

MKE047

10 m/s²

1000 m/s²

MKE098

10 m/s²

300 m/s²

MKE118

10 m/s²

200 m/s²

8

Assembly

8.1

Flange assembly

NOTICE

Motor damage due to ingress of liquids!

Liquid which exists over a longer period on the

shaft sealing ring of the output shaft can ingress

into the motor and cause damage.

−

Ensure that liquid cannot be present at the

output shaft.

−

Do not mount any open gearboxes (gear-

boxes that are not hermetically sealed).

Use all motor mounting holes to mount the motor

safely to the machine. For details on mounting

holes, please refer to the dimension sheets.

•

If coupling is direct, ensure that the support

is plane and the orientation is precise.

•

Avoid pinching or jamming the centering

collar on the motor side.

•

Avoid damaging the receptacle fit on the

plant side.

•

Use screws and washers for flange assembly

according to

.

8.2

Assemble transmission

elements

NOTICE

Motor damage due to strikes onto the motor

shaft

Do not strike the shaft end and do not exceed the

allowed axial and radial forces of the motor.

Fit and pull off the transmission elements such as

pulleys and couplings only with suitable equip-

ment; heat them, if necessary.

•

Avoid inadmissible belt tensions. Please con-

sider the allowed radial and axial forces in the

project planning manuals.

•

The balancing state of transmission elements

must comply with the full-key balancing of

the motors.

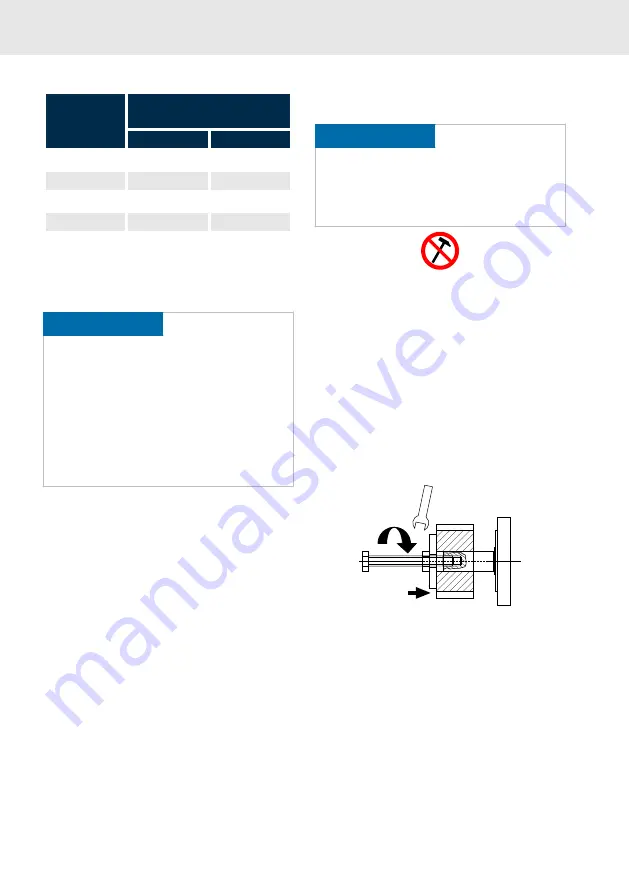

Fitting

Fig. 6: Fitting the transmission element

•

Use the centering hole for fitting transmis-

sion elements. For details on centering holes,

please refer to the specifications.

•

Heat the transmission element, if necessary.