Shaft with keyway

Cylindrical shaft end according to DIN 748-3 with frontal centering hole with

"DS" thread according to DIN 332-2 and keyway.

The keyway design allows form-locking transmission of torques with constant

direction and low requirements on the shaft-hub connection.

The machine elements to be driven have to be secured in axial direction via

the centering hole.

Type

Key DIN 6885-A

Centering hole DIN 332 Part 2

MS2E03-B

3×3×14

DS M3

MS2E03-D

4×4×16

DS M4

MS2E04

5×5×20

DS M5

MS2E05

6×6×32

DS M6

MS2E06

8×7×40

DS M8

MS2E07

10×8×45

DS M10

MS2E10

10×8×70

DS M12

Tab. 4-6:

Keys and centering hole for MS2E motors

Keys are not included in the scope of delivery.

We recommend regular visual inspections on shaft sealing rings. Depending

on operating conditions, signs of wear may appear after 5,000 operating

hours. If necessary, replace the shaft sealing rings.

We recommend to have these repairs made by Bosch Rexroth

Service.

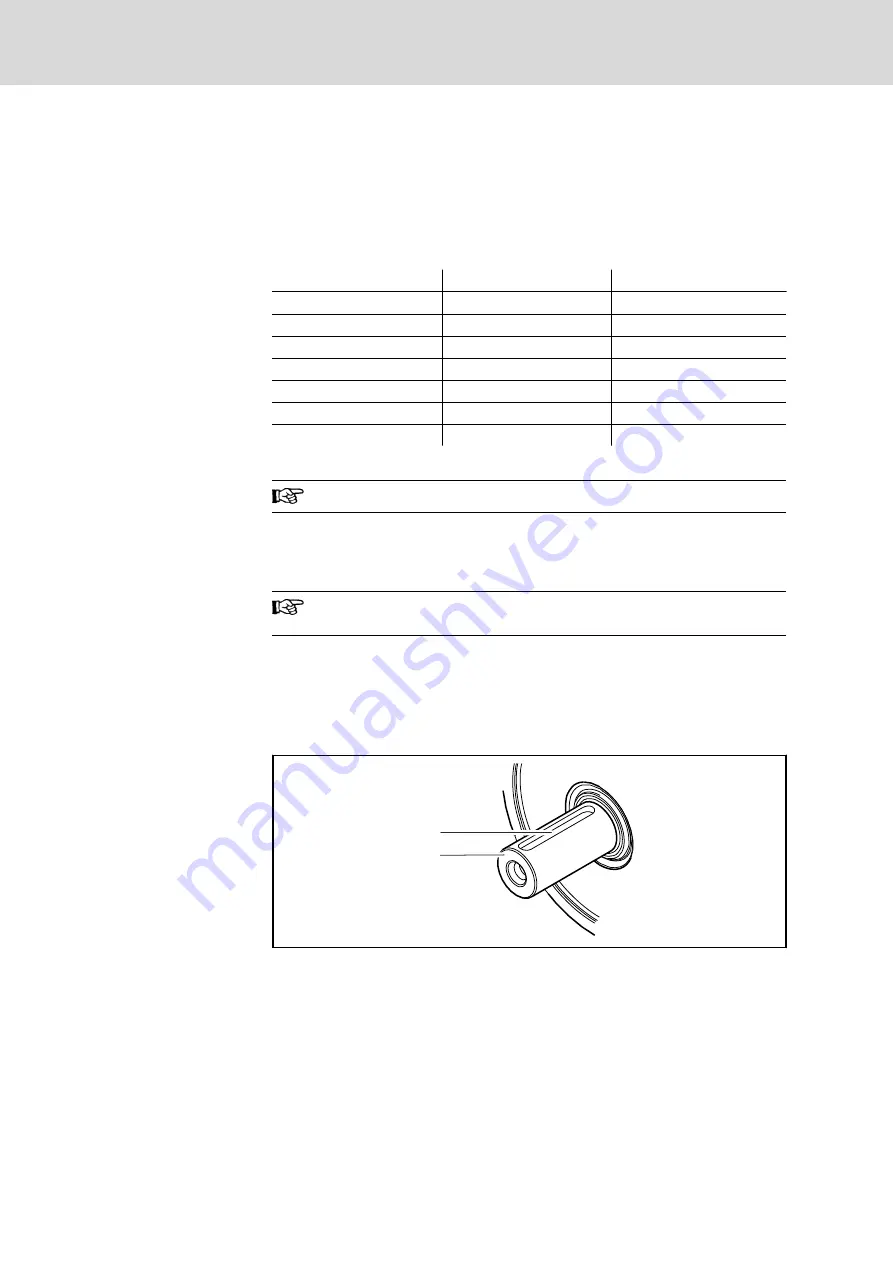

Winding

MS2E motors with key are balanced with "half key". Half key balancing ac‐

cording to DIN ISO 21940-32.

The balancing type is specified at the shaft front end with "H" for half key bal‐

ancing.

H

1

2

H

1

Centering hole

2

Labeling balancing

3

Keyway

Fig. 4-2:

Shaft end

Attachment of drive elements

Refer to the notes regarding the installation of drive elements.

Explosion protection

When mounting drive elements, check their suitability and keep the ATEX di‐

rectives during operation. Selecting of all mounting components underlies the

sole responsibility of the plant manufacturer or operator.

14/65

About this product

MS2E Synchronous Servomotors acc. to ATEX Directive

2014/34/EU

Bosch Rexroth AG R911387136_Edition 02