44/96

Pressure and flow control system SYDFE1 series 2X, 3X

| Mounting

Bosch Rexroth AG, Edition 10.2021, RE 30011-B

SYD_015

+

-

=

b

a

c

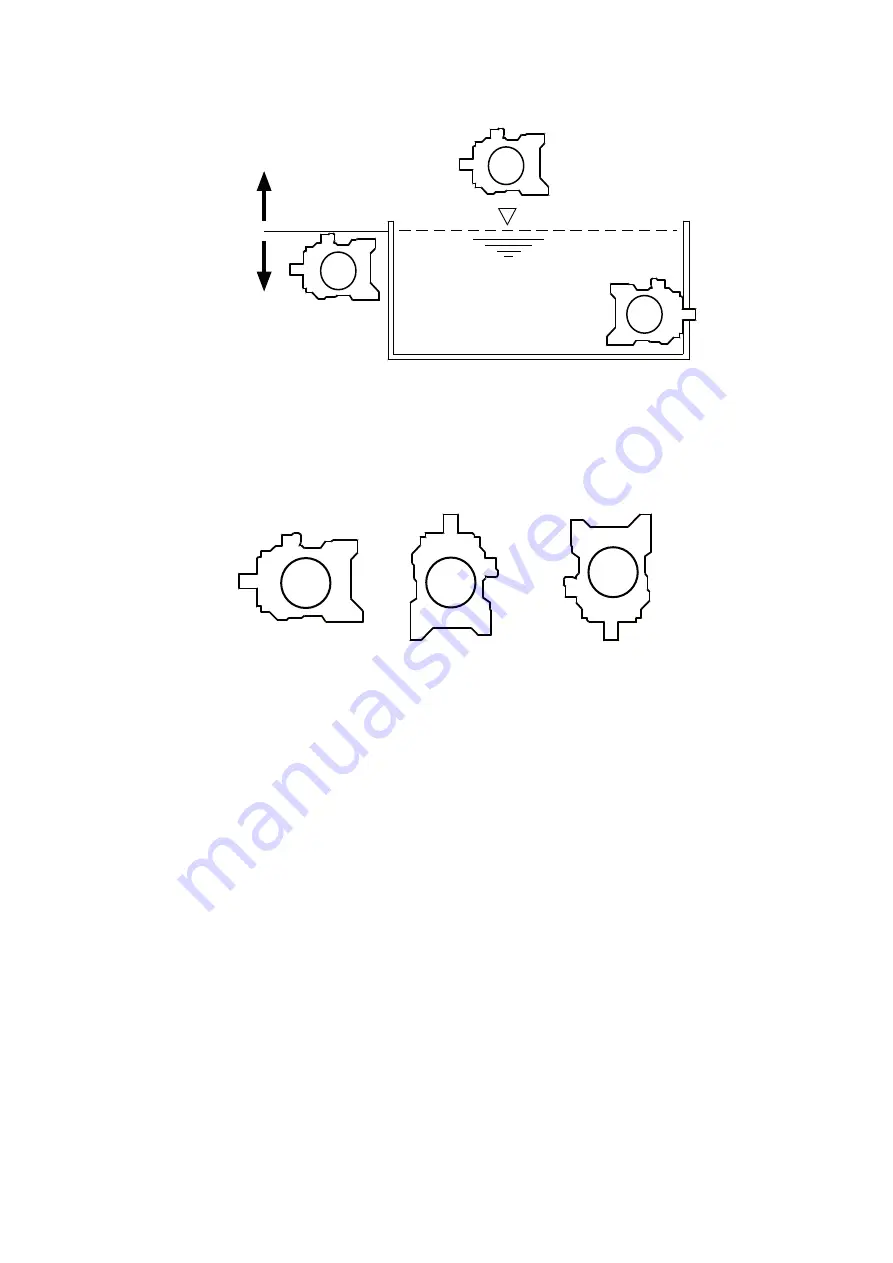

Fig. 18: Installation position

The following installation orientations are possible:

• Pos.1 horizontal: Shaft end horizontal

• Pos.2 vertical: Shaft end upwards

• Pos.3 vertical: Shaft end downwards (possible only with pump variant 0975)

SYD_016

3

2

1

Fig. 19: Installation orientations

7.3.2 Piping

The installation positions and installation orientations shown in Figs. Fig. 18 and

Fig. 19 determine the installation of

• suction lines

• case drain lines

• bleed lines

Make sure for all installation positions that always the higher of drain ports “L”

or “L1” is piped. Moreover, the distance between the end of installed pipes and

the minimum oil level must not be shorter than the specified minimum distance

(immersion depth “E”)

When installing suction and case drain lines, take care that the routing is straight

and short and has as few bends as possible.

When the system is at rest, the lines drain automatically in the course of time due

to the own weight of the hydraulic fluid.

Moreover, the different specific densities of hydraulic fluids must be taken into

account, since fluids with a higher density are more difficult to aspire and also

flow down more quickly. The limit speeds for hydraulic fluids with high density

(≥ mineral oil 0.87 g/ml) are specified in data sheet RE 90223.

Installation orientation

To be noticed