52/96

Pressure and flow control system SYDFE1 series 2X, 3X

| Mounting

Bosch Rexroth AG, Edition 10.2021, RE 30011-B

7.6

CONNECTING THE SYDFE1 CONTROL SYSTEM

ELECTRICALLY

The machine or system manufacturer is responsible for setting up the electrical

control.

With electrically controlled SYDFE1 control systems, the electrical control must be

connected according to the circuit diagram of the machine or system manufacturer.

The VT 5041-3X control electronics is connected using a 32-pin female multipoint

connector and can be installed in a Euro rack or in a card holder from Rexroth

(VT3002 according to RE 29928).

CAUTION

! Live installation!

Risk of injury when plugging or unplugging connectors under voltage.

▶ Before carrying out any installation work or plugging or unplugging connectors

from the product, disconnect the device from the power supply or the voltage

source or de-energize it reliably. Damage to the control system caused by

incorrect installation is not covered by the warranty!

1.

Disconnect the relevant system part from the power supply.

2.

Connect the SYDFE1 control system electrically (24 V).

7.6.1 Cabling of electronic components

Generally, the following is valid:

– Use low-capacitance cables according to the safety regulations of the German

VDE or national electrical safety regulations of your country. Whenever

possible, establish the cable connections without intermediate terminals!

– Select only cables that have the actually required number of wires (avoid

superfluous wires).

– The installation of electromagnetic sources of interference, e.g. unearthed

contactors, in the direct vicinity of the pilot valve is not permitted.

– Installing power cables in the vicinity of the control electronics is not

permitted.

– No switches or relay contacts may be installed in the electrical connections

between the pump/proportional valve and control electronics, because

breaking of a connection results in fault messages or malfunctions. Whenever

possible, do without intermediate terminal points or reduce their number to a

minimum.

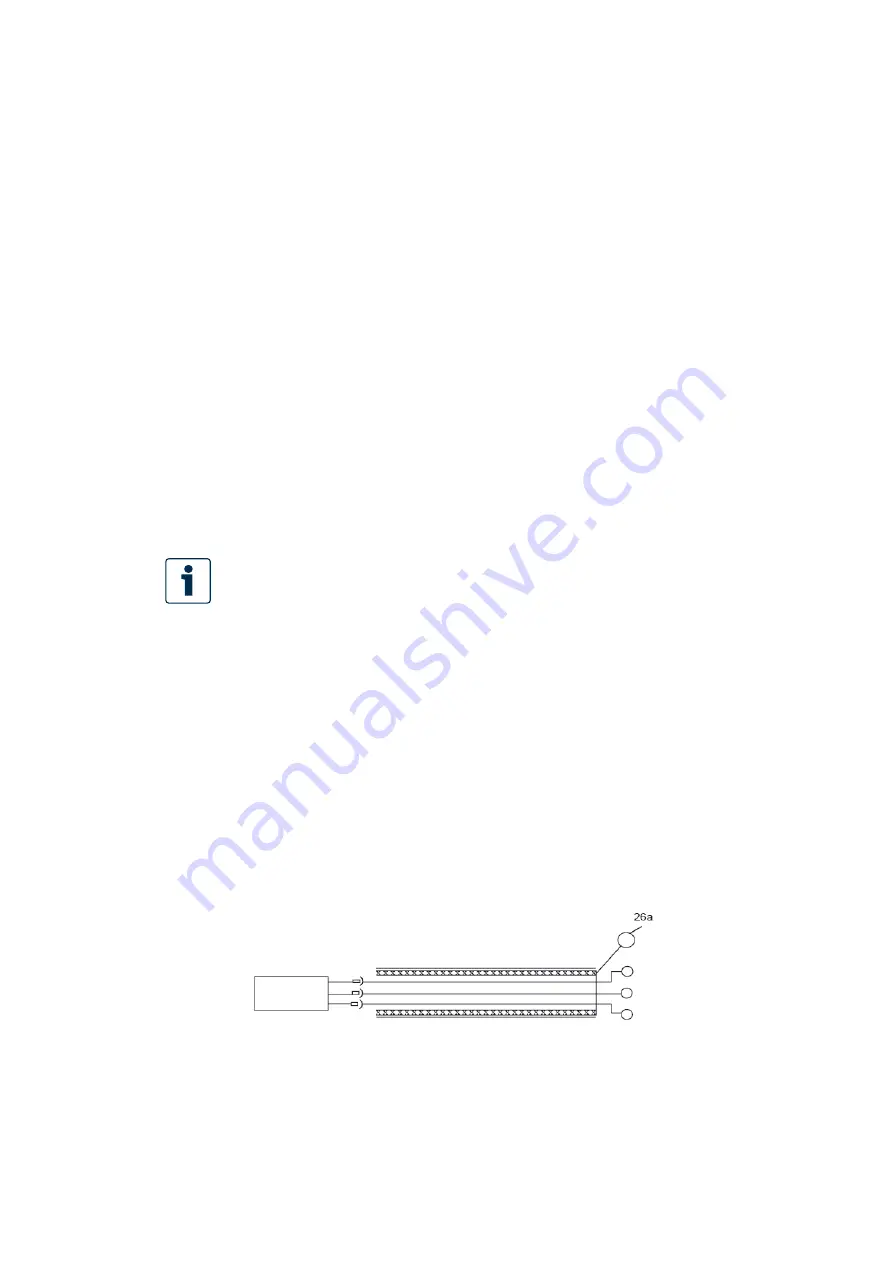

– Cables of inductive position transducers, swivel angle sensors and of the

pressure transducer must be shielded. Connect the shield only on one side

to the control electronics (see Fig. 22). Never connect the shield to the valve,

pump or pressure transducer.

The shield is not to be connected

at the connector to the

transducer

Transducer

The shield is brought out and

connected to 26a

Fig. 22: Connection of the cable shield