RE 30011-B, Edition 10.2021, Bosch Rexroth AG

Product description |

Pressure and flow control system SYDFE1 series 2X, 3X

19/96

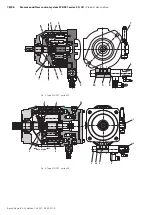

The sectional drawings overleaf show the mechanical basic position “+100 %“ of

the pump (depressurized, drive at rest). This corresponds to the maximum swivel

angle of the pump.

Zero stroke pressure: Pressure, which the pump with internal supply generates for

its own supply without activation of the pilot valve. The pressure level is usually

within the range of 8 to 12 bar. This pressure level can only be achieved when the

maximum oil flow, which the pump can deliver, is not exceeded. After the electric

drive was started, the pump with

internal supply

automatically swivels in to zero

stroke operation

• when the enable of the control electronics is

missing

or

• in the case of an error message of the control electronics (condition: VT 5041-

3X: J1 OFF) or

• in the de-energized state of the control electronics

provided that the required pilot pressure can be built up (consumer line is

closed).

In contrast to this, the pump with

external supply

swivels in to the

negative limit

stop “-100 %“

under the above conditions

!

NOTICE

! Cavitation of the pump!

Risk of damage to the pump in the case of systems with external supply.

▶ To prevent damage to the pump, provide a pressure relief/anti-cavitation valve

for systems with external supply. If a fault occurs during operation - not during

start-up - the motor must be switched off.

5.3

CONTROLLER STRUCTURE AND BASIC OPERATING

MODES

The controller structure is illustrated in the figure below.

Fig. 4: Controller structure

Up to three controllers are continuously active in the possible operating modes:

• Swivel angle controller

• Pressure controller

• Power limitation (optional)

These controllers alternate automatically and jerk-free through evaluation of

minimum value comparators.

During steady-state operation, one of the above controllers is active. For the other

controllers, the actual value is smaller than the command value.

Basic positions of the

swivel angle adjustment

feature

Controller structure

SYD_006

s

U

U

p

s

U

Power

controller

(option)

(Pin 24c)

Actual pressure (pin 8c/10c)

Pressure

controller

Minimum

value

comparator

Flow

controller

Minimum

value

comparator

Valve

controller

Valve command value

Power setpoint

(potentiometer or

pin 18c/20c)

Swivel angle setpoint

(pin 14c/16c)

Actual swivel angle (pin 12c)

Pressure setpoint (pin 6c/4c)

Basic operating modes