RE 30011-B, Edition 10.2021, Bosch Rexroth AG

Product description |

Pressure and flow control system SYDFE1 series 2X, 3X

29/96

The details given for the noise pressure level in the technical documentation refer

to measurements taken in an anechoic chamber. Influences of the surroundings

such as place of installation, general mechanical concept, piping, etc., are not

taken into account.

5.8.1 Generation of noise in the power unit

“Noise“ is composed of various elements. The total result of “noise” is influenced

not only by air-borne noise, but also by structure- and fluid-borne noise.

As a result of unfavorable installation and piping conditions, the noise pressure

level of the complete system can be 5 to 10 dB(A) higher than the value of the

pump alone.

Noise can be reduced by taking, for example, the following measures:

• Low-noise tank

• Damping ring between pump and pump mounting bracket

• flexible pipe conduit

• Anti-vibration rails under the motor

• Installation of the pump at a sufficient distance to the tank wall

5.8.2 Pulsation damper

For some special applications, we recommend the use of a pulsation damper. Due

to the reduction of typical pump pressure pulsation, this has a positive effect on

the noise level of the hydraulic system as a whole.

Further information can be found in data sheet RE 50142.

5.9

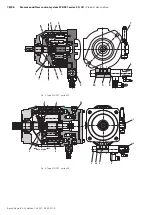

SHAFT VARIANT

The SYDFE1 control system is available with keyed or splined shafts. When

compared with the keyed shaft, the splined shaft is not only advantageous with

regard to its degrees of freedom during assembly and operation, but also due to

its increased torque load carrying capacity and its stability under changing loads.

This increased torque load carrying capacity is useful in particular when pump

combinations are to be installed. In the case of multiple pumps, all built-on units

are fitted with splined shafts.

In view of the dynamic load carrying capacity and standardization, we recommend

the use of standard types with splined shafts. This offers advantages with regard

to availability and future spare parts requirements.

When a splined shaft is selected, a clamp coupling must be used for the

mechanical connection to the electric motor. Otherwise, frictional corrosion may

occur that leads to damage to the pump.

Notes on the transmission of permissible maximum torques can be found in the

data sheet.

Due to the advantages of the splined shaft, keyed shafts are

not

recommended for

new applications. The keyed shaft is no longer used for applications with through-

drive.

If a single pump is to be used later as “end pump” in a multiple-pump system, a

splined shaft must be selected.

Keyed shaft