52/96

SYDFED-2X, SYDFED-3X, SYHDFED-1X

| Installation

Bosch Rexroth AG, Edition 11.2021, RE 30017-B

7.6

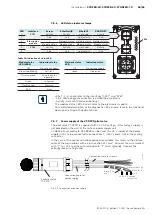

CONNECTING THE SY(H)DFED CONTROL SYSTEM

ELECTRICALLY

The machine or system manufacturer is responsible for setting up the electrical

control.

For electrically controlled SY(H)DFED control systems, the electrical control

must be connected according to the circuit diagram of the machine or system

manufacturer.

Damage to the control system caused by incorrect installation is not covered by

the warranty!

CAUTION

! Live installation!

Risk of injury when plugging or unplugging connectors under voltage.

▶ Before carrying out any installation work or plugging or unplugging connectors

from the product, disconnect the device from the power supply or the voltage

source or de-energize it reliably. Damage to the control system caused by

incorrect installation is not covered by the warranty!

1.

Disconnect the relevant system part from the power supply.

2.

Connect the SY(H)DFED control system electrically (24 V).

7.6.1 Cabling of electronic components

Generally, the following is valid:

– Keep the number of intermediate terminals to a minimum.

– The arrangement of electromagnetic sources of interference in the direct

vicinity of the pilot valve is not permitted.

– Installing power cables in the vicinity of the pilot valve is not permitted.

– Due to the use in a hydraulic environment, use only cable material that is

specified as “oil-proof”. Otherwise, possible hardening of the cable jacket

could lead to embrittlement and thus to breaking of individual wires.

– Select only cables that have the actually required number of wires (avoid

superfluous wires).

– Cables for command values and actual values should be as short as possible.

– The signal cables to the pilot valve must in any case be shielded. The cable

shield must be connected to ground on one end in the control cabinet.

– Strip the shield as short as possible and connect it in accordance with the

data given in the RE data sheets.

– The contacts on the mating connector must not be exposed to mechanical

stress. This can lead to a defective connection between the mating connector

and the plug-in connector.

Due to the fact that the control electronics is integrated in the valve housing in the

factory, no additional cabling is required for the position transducer systems of the

pump and the valve.

Cabling of the control system is therefore restricted to the connection of the 12-

pin central connector of the integrated electronics to the customer’s control, the

pressure sensor and the field bus connection, if provided.

For this connection, ready-to-connect and standardized cable kits are available

in different lengths. On request, the 12-pin mating connector can be supplied

separately for individual designs. See data sheet.

The HM20-2X/...-F-C13 pressure transducer is fitted with a ready-to-connect,

standardized connection cable for direct connection to the X2M1 or X2M2

connection port.