RE 30017-B, Edition 11.2021, Bosch Rexroth AG

Troubleshooting |

SYDFED-2X, SYDFED-3X, SYHDFED-1X

83/96

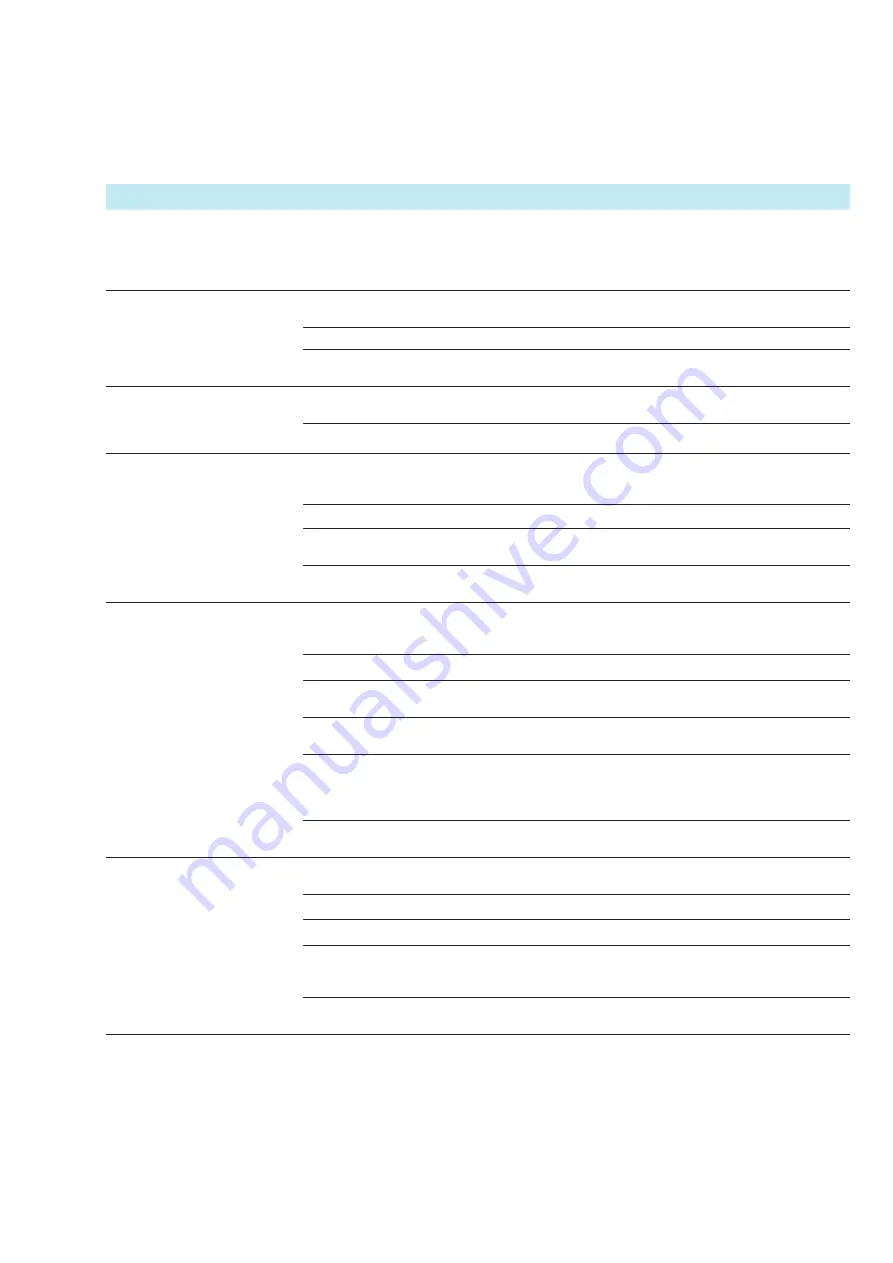

15.3 FAULT TABLE

Table 28: Fault table of SY(H)DFED control systems

Malfunction

Possible cause

Remedy

Message “analog input, wire

break” at actual pressure value

input

Actual pressure value of the relevant

pressure transducer fell below or exceeded

the limit value, that is, the value is outside

the permissible measuring range of the A/D

converter.

Test actual pressure value signal (wire

rupture, working range, signal type,

polarity)

Message “Wire rupture of

swivel angle sensor”

Defective swivel angle sensor cable (visual

inspection)

Replace swivel angle sensor

Defective swivel angle sensor

Replace swivel angle sensor

Internal electronics fault

Have the pilot valve repaired by Rexroth

Service or replace pilot valve

Message “Valve error pump

controller” (deviation between

command and actual position

of the valve spool)

Valve spool jams due to contamination

Replace pilot valve (see page 76),

contact Rexroth Service

Internal electronics fault

Replace pilot valve, see page 76

Message “Control deviation

pump controller”

Backpressure cannot be built up (minimum

pressure at the pump 8...10 bar)

Check that the hydraulic system is

leak-free and there is no excessive oil

consumption

Drive motor switched off or speed too low

Check electrical control and motor control

Valve spool does not move as a result of

electronics fault

Replace pilot valve, see page 76

Valve spool jams due to contamination

Replace pilot valve (see page 76),

contact Rexroth Service

Humming noise in the pressure

control or fluctuations in

pressure/flow

Air cushion around the sensor

Bleed control system, pre-load valve (see

chapter 8.1.7 on page 65) and pipes

completely

Problem with the cable shield

Connect shield to ground

Incorrect protective earth connection in the

control cabinet

Properly connect protective earth

connector

No connection from M0 to L0

Connect M0 (XH4, pin 4) and L0 (XH4, pin

2) in the control cabinet

Unfavorable place of installation/mounting

technique for the pressure transducer

Change place of installation (e.g.

suspended mounting, no minimess line,

no throttling point between pump and

pressure transducer), see page 57.

Improperly high gain of the actual pressure

value

Reduce P-gain, see chapter 8.1.8.1 on

page 66

Screaming noise

Oil level in the tank too low; pump partly

aspires air

Top up oil

Pump aspires air

Change routing of the suction line

Suction line leaky

Seal suction line

Pump cavitates when pressure is reduced

Diagnostics: Measure, whether the pressure in

the pressure line overshoots

Optimize controller, reduce the command

value via a ramp or in steps

Fluid in the tank mixed with air; cooling and/or

filtration circuit leaky

Seal