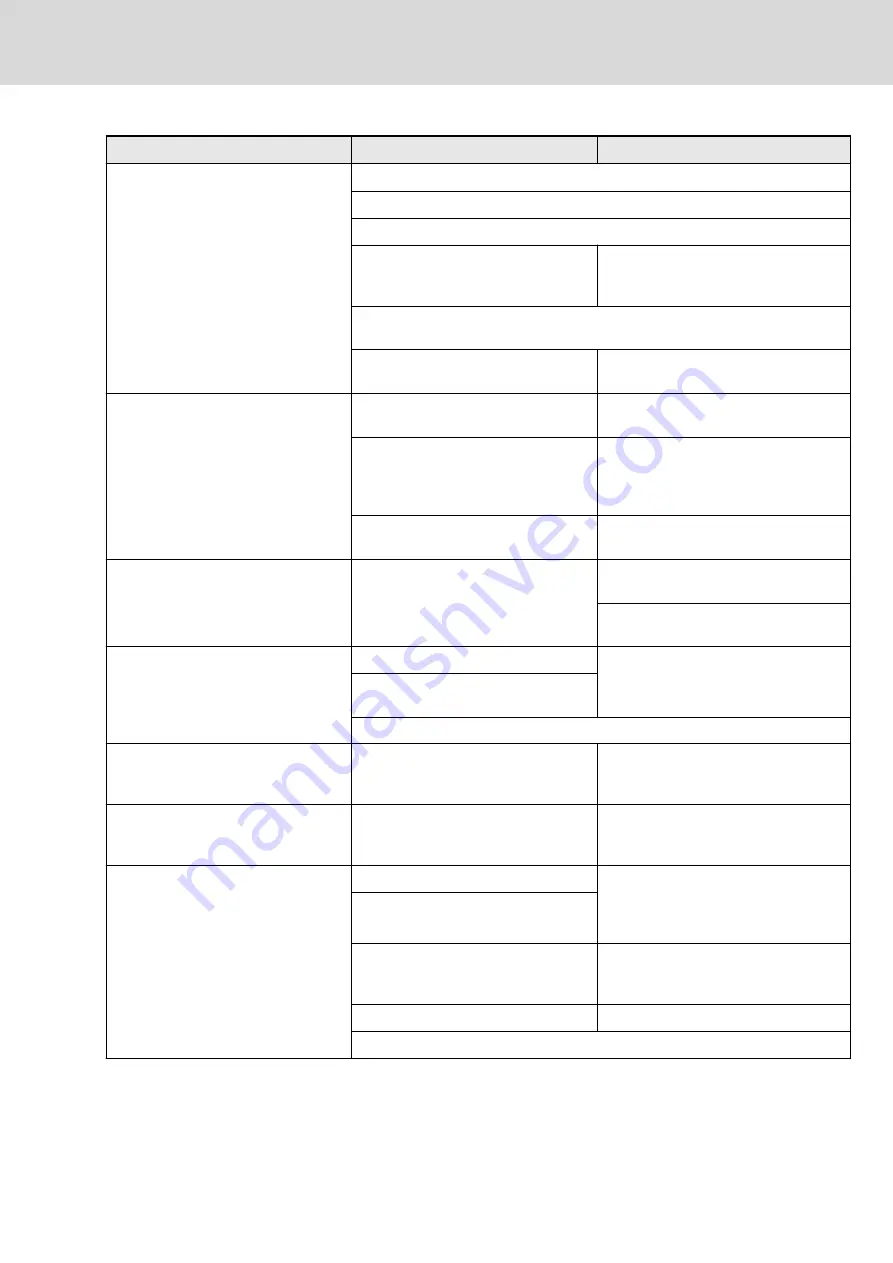

Malfunction

Possible cause

Remedy

Volumetric or mechanical efficiency is

not achieved

See malfuntions "Viscosity >300 mm

2

/s"

See malfuntions "Viscosity <10 mm

2

/s"

See malfunctions "Output flow is not achieved"

Operation projected with too low and/or

too high speed

Observe the notes in the project plan‐

ning manual "RE 10227 (PGH.-3X) / RE

10223 (PGH.-2X) / RE 10213 (PGF)".

See malfunctions "Admissible level of contamination of the hydraulic fluid excee‐

ded"

Mixing of different fluids

Observe the information on hydraulic flu‐

ids in RE 90220

Admissible level of contamination of

the hydraulic fluid has been exceeded

Fluid aging and abrasion from system

Check the fluid contamination according

to the maintenance schedule

Insufficient filtration

Observe the notes in the project plan‐

ning manual "RE 10227 (PGH.-3X) / RE

10223 (PGH.-2X) / RE 10213 (PGF)"

and check the fluid contamination.

Unexpected inlet of contamination (e.g.

in case of fluid exchange)

Provide for a clean environment, filling

only via filter

Wrong direction of rotation of the drive

motor

Drive motor corrected incorrectly

Assembling only by authorized, trained

and instructed experts

Check the direction of rotation in case of

recommissioning after mains separation

Protective motor switch is activated

Drive motor too weak

Observe the necessary drive power in

"RE 10227 (PGH.-3X) / RE 10223

(PGH.-2X) / RE 10213 (PGF)".

See malfuntion "Wrong connection of

drive motor"

See malfuntion "Pump wear"

Input speed too high/too low

Motor projected with too low and/or too

high speed

Observe the notes in the project plan‐

ning manual "RE 10227 (PGH.-3X) / RE

10223 (PGH.-2X) / RE 10213 (PGF)".

Air inlet through the output side

O-rings defective (wrong medium,

damage to the sealing, missing O-ring,

wrong O-ring)

Use the original combination part set, re‐

place the seals

Fluid leakage

Tank hangs too high

Observe the project planning information

in maintenance and commissioning of

hydraulic components RE 07800 / RE

07900

Fluid level too high

Pre-charged fluid tank (too high pres‐

surized) and/or pre-filling pump

Observe the project planning information

for pre-charged tank and/or pre-filling

pump

Defective seal

Exchange the damaged O-ring

See malfunctions "Interfaces not tight"

DOK-SYTROX-MPES2******-IT01-EN-P

Rexroth Sytronix FcP 50xx/70xx Motor-Pump Unit MPES2

Bosch Rexroth AG

91/143

Troubleshooting

LSA Control S.L. www.lsa-control.com comercial@lsa-control.com (+34) 960 62 43 01