46

Bosch Rexroth AG

| Tightening Technology

3 608 878 300

System 350

| 3 608 878 300/2019-03

3.4.3

Tightening spindles

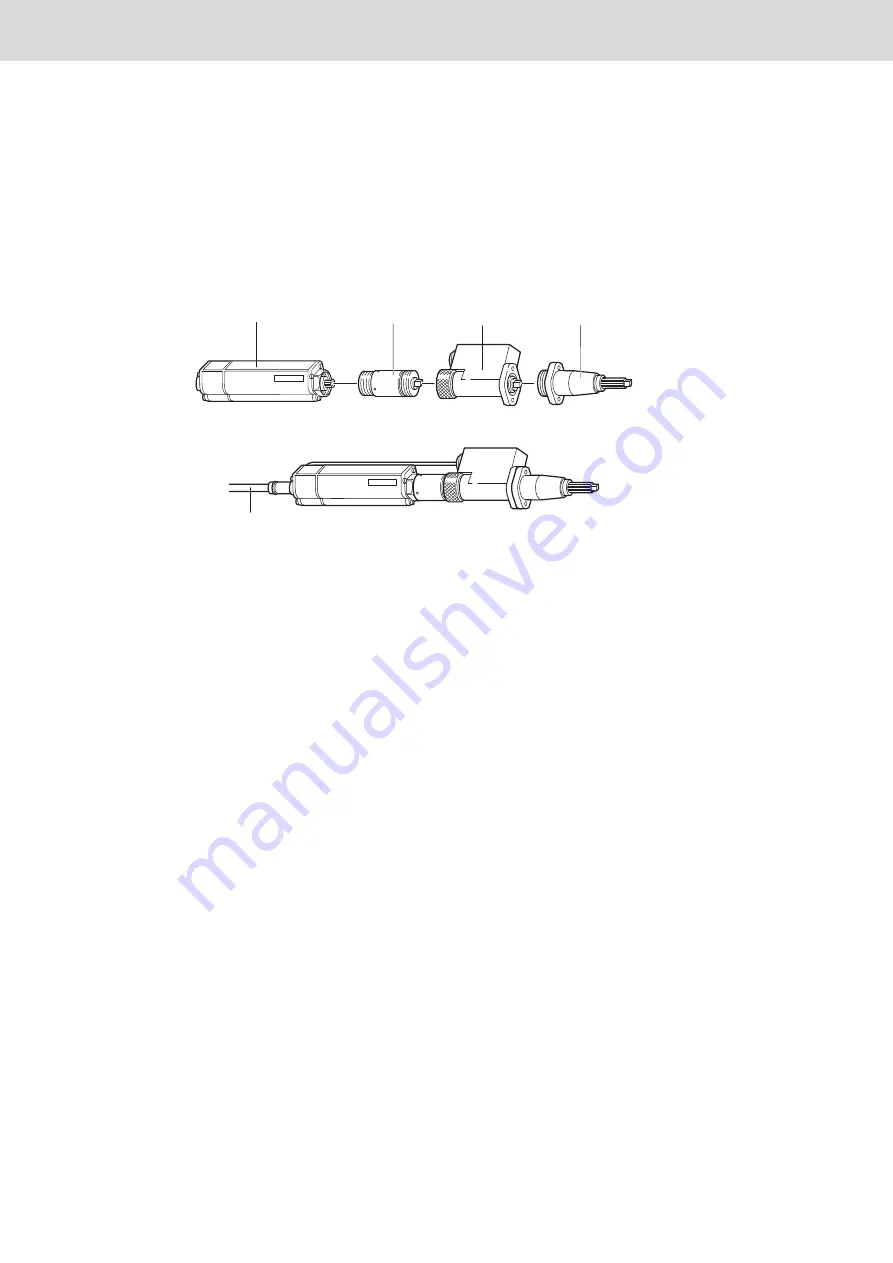

The modular design of Rexroth's tightening spindles (Fig.

) allows for very exact adjustment to the

tightening job and the precision requirements. You can obtain the highest possible level of system

reliability by installing a redundant measurement transducer in the tightening spindle.

The tightening spindles are available in the sizes 2/3/4 and 5, depending on the torque requirements. The

correct selection of the size has to be implemented separately for each tightening job and is explained in

more detail in chapter

.

The following figure shows the design of a straight tightening spindle:

Fig. 3–11:

Modular tightening spindle design

Drive unit

EC motor (1)

The EC motor is maintenance-free and easy to install. Its compact exterior dimensions ensure short

tightening times and high dynamics.

Planetary gearbox (2)

The space-saving planetary gearbox converts the low motor torque into a high output drive torque and

thus obtains a high level of efficiency. The planetary gearbox is simply bolted to the EC motor. Several

gearboxes are available per series, for use in various applications.

Measurement

transducer (3)

The measurement transducer is designed as a contact-free, maintenance-free action transducer. The

measured values (e. g. torque, angle of turn, and gradient) are processed directly in the measurement

transducer. It is equipped with an integrated cycle counter and can also be used as a redundancy

transducer. The measurement data is digitally transferred from the measurement transducer to the

tightening controller via a standard bus system and is thus resistant to interference.

Output drive (4)

Numerous different output drives are available for various applications. You can choose between straight

output drive, offset output drive with integrated transducer, angle head, angle head with integrated

measurement transducer or feed output drive, among others.

The offset output drive with integrated measurement transducer and angle head with integrated

measurement transducer features torque measurement directly at the bolt and measured value transfer

without slip ring. Thus, the measured values are not influenced by fluctuations in efficiency.

Tightening spindle

connection cable (5)

The connection between servo amplifier and tightening spindle is implemented with a single cable. This

cable requires little wiring effort and is exceptionally sturdy, providing safety advantages for applications

in which the tightening spindle is in constant motion, e. g. in systems with robotic arms. A maximum

distance of up to 100 m can be safely bridged.

(1)

(2)

(3)

(4)

(5)

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...