3 608 878 300

Tightening Technology |

Bosch Rexroth AG 477

System 350

| 3 608 878 300/2019-03

6.12.4

Configuring the PLUS Protocol connection in the BS350 operating system

The configuration window for PLUS in the BS350 operating system can be opened in two different ways.

This depends on the question whether the BS350 is connected to a tightening system ("online") or not

("offline"):

•

Online:

System

PLUS configuration

•

Offline:

File

New

PLUS configuration

Connection parameters

Operation parameters

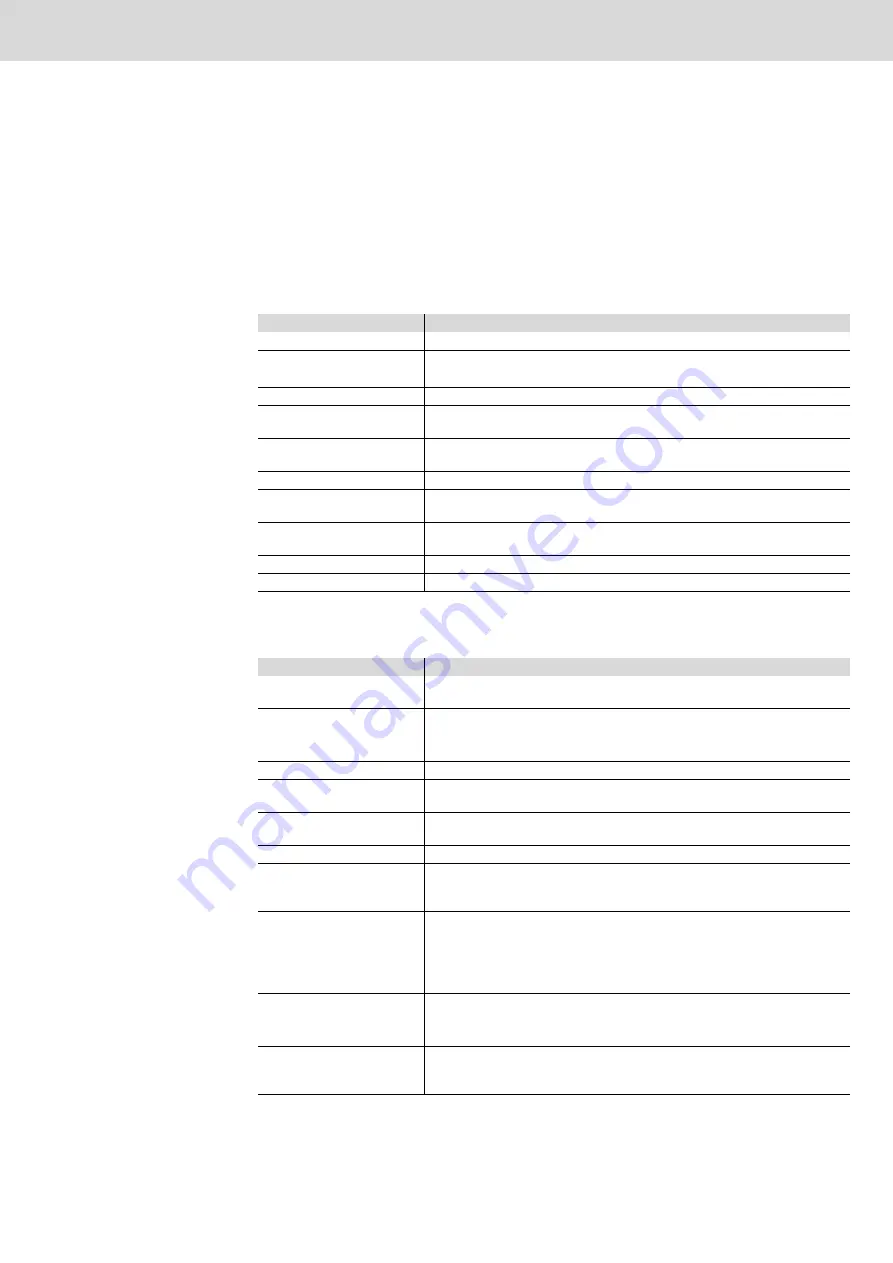

Table 6–152:

Settings in BS350 for PLUS - Tandem parameters

Element

Description

Port

PLUS server port.

IP filter

Default setting: 0.0.0.0 – allows communication with every tandem server

Fixed IP address entered – allows communication with only one entered server

Coupling no.

Specified by Daimler.

Resync with Conn.

Synchronization (block counter) after the connection to the server has been

established.

Ackn Timeout

Waiting time within which a telegram must have been acknowledged (in

milliseconds).

Response Timeout

Waiting time of a request until the response is given (in milliseconds).

Q1 repeat

Specifies how often the data must be sent again after PLUS has given a negative

response.

Resync after Q1

Synchronization (block counter) after a negative response from the BS350

tightening system.

Users

Parameter for data field in the PLUS Protocol

Error code

Error code for non-tightened tightening positions (default: N31)

Table 6–153:

Settings in BS350 for PLUS - OP

Element

Description

OP

Operation 1 to Operation 8 – Selects the operation for which the parameters are to

be set.

Active

Specifies whether the operation selected is to be used.

Note: Operations are processed sequentially. The first inactive operation defines the

total number of active operations.

Delete OP

Deletes the operation selected.

ID

Unique identifier of the operation selected – cannot be edited! Only for BS350, is

not used in the PLUS Protocol.

Name

Name for the operation selected, can be selected as desired. Only for BS350, is not

used in the PLUS Protocol.

Production point

Specifies the production point at which the operation is performed.

ID filter

Allows selecting/filtering certain areas from the complete ID If you enter “I" here, the

character is applied at the place in the PLUS ID code that is identified by “I". If you

enter an asterisk ("*"), the character is ignored.

ID_PosMask

Individual positions from the complete ID code can be masked for further

processing in IndraLogic (IL), e.g. for program selection. If you enter "P" here, the

character is applied at the place in the PLUS ID code that is identified by "P". If you

enter an asterisk ("*"), the character is ignored.

ID type request/

ID type station

Defines the ID type inquired:

KNR (car body number), PNR (production number) LTR (carrier number) or VTI

(variable ID)

Operating mode

Parameter for transferring the operating mode to the IL for execution. The IL requires

this information in case of a generic IL program. Whether or not this information is

used, depends on the IL.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...