478

Bosch Rexroth AG

| Tightening Technology

3 608 878 300

System 350

| 3 608 878 300/2019-03

Component type parameters

Right-click the header of the table to create a new activity pattern or delete an existing activity pattern.

Tightening tool assignment

Right-click the header of the table to create a new quality identifier or delete an existing quality

identifier.

For each tightening result, the following table is searched to assign the suitable quality identifier for the

combination of channel, application/program and position for data output.

6.12.4.1

Enabling PLUS

Via

System

Tightening cell data

PLUS

, the data protocol can be enabled.

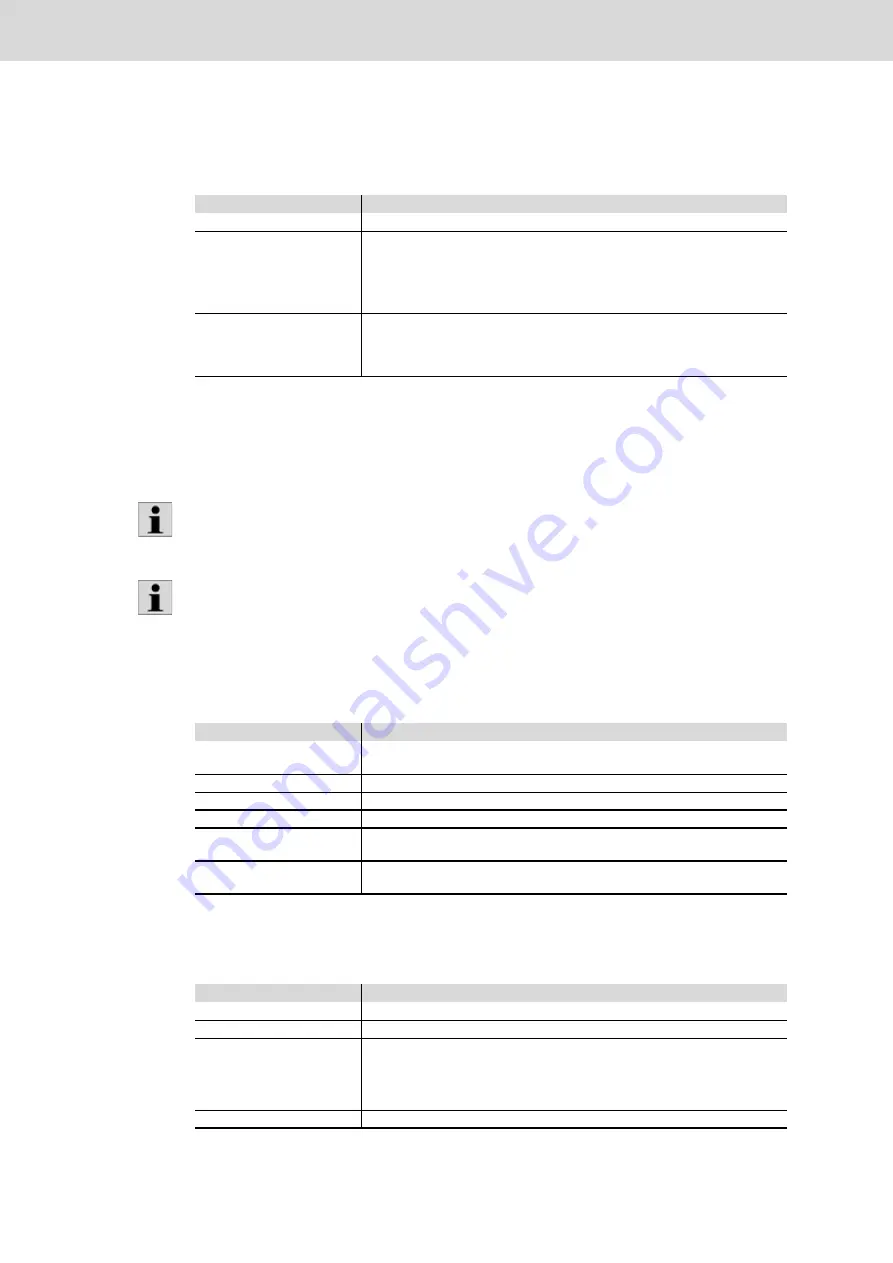

Table 6–154:

Settings in BS350 for PLUS - Component type parameters

Element

Description

Cons. no.

Irrelevant.

Activity pattern

Selects the activity pattern for controlling the sequence.

The activity pattern is a 32-digit text, consisting of "1" and "0". The content defines

how a component is to be processed (e.g. number of tightening positions, program

number, etc.). To achieve this, a unique assignment is defined between PLUS and

the tightening system, which will then have to be configured accordingly.

Type/App/Prgnummer

and application type

Transfer parameter for the IL so that sequences can be incorporated flexibly. In a

(limited) generic case, the IL can then describe a complete tightening process.

Alternatively, the IL can ignore these fields and control the sequence using the IL

program.

The

Pos

field is only used if the

ID_PosMask

(see table

6–152

) is set respectively. In this case, the

number of characters in

Pos

and

ID_PosMask

has to be identical.

For Integra 6 with the standard Integra PLC interface, the

Activity pattern

field is not used as here, the

system always works in the "Work and Send” mode. The field can, however, be used as information.

The superior station PLC must request the activity pattern from PLUS and decode it into a type number.

This type number is forwarded to the tightening system via the PLC interface and compared to the list of

component type parameters.

Table 6–155:

Settings in BS350 for PLUS - Component type parameters

Element

Description

Active

Specifies whether the particular tightening is output (activated) or discarded

(deactivated)

Channel

Selects the channel pertaining to the operation

App

Application number

Prg

Program number

Pos

Tightening position Can be set at runtime by ID/Job/IL. As a result, "stitching" is

possible with unique tightening position assignment.

QI

Quality identifier. Based on the combination of App, Prg and Pos, a tightening result

is uniquely assigned to a tightening position and its QI.

Table 6–156:

Settings in BS350 for PLUS activation

Element

Description

Activated

The data protocol is active if this option is selected.

Version

Data protocol display:

Rexroth PLUS 1.0

Open...

Loading of stored data from a file.

Click this button to open a PLUS configuration file (

*.dcg

file).

The

*.dcg

files can only be opened with the dialog window under which they have

been saved.

Save as ...

Saving of data to a data carrier.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...