3 608 878 300

Tightening Technology |

Bosch Rexroth AG 589

System 350

| 3 608 878 300/2019-03

IMpdp

You can make the following settings in the

Set up Profibus DP interface

group:

No settings can be made in the

Configured ranges

field: The grayed out fields cannot be edited. The

parameters displayed in this field depend on the selected number of I/O points.

A participant profile in form of a GDS file (Generic Station Description - master data file) is required for

commissioning of the IMpdp interface module. The GSD file (

*.

gsd

) allows the software to recognize the

adjustable parameters and their value ranges.

After setting all parameters, create the master data file by clicking

Create GSD file

.

Save the file and

import it into the field bus configurator.

Click

Accept

to take over this data in the configuration for the tightening channel in the BS350.

The indicated value ranges are maximum values that can only be fully used if the other parameters have

not been set to the maximum value.

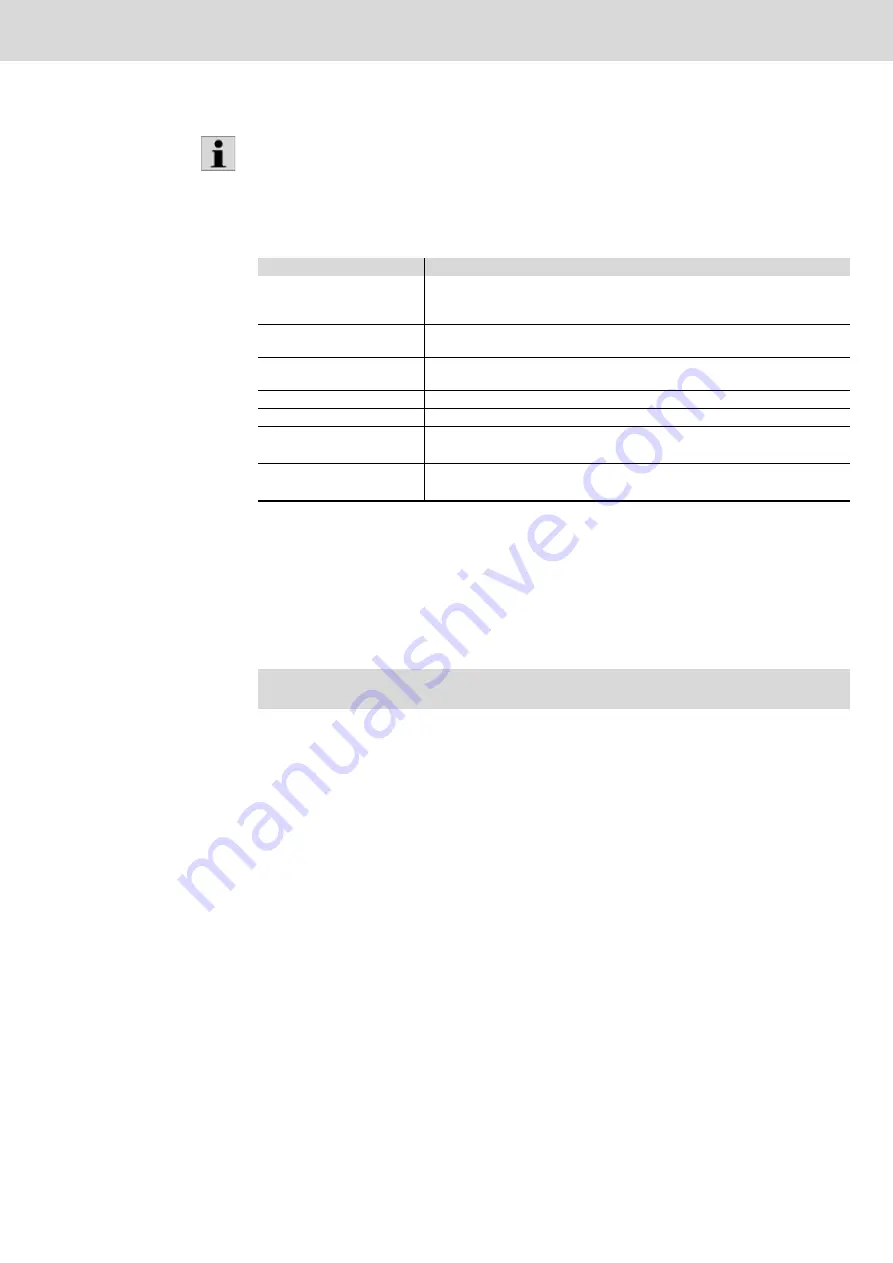

Table 7–26:

Settings in BS350 for IMpdp - I/O and data

Element

Description

Station address

Address of the IMpdp in the PROFIBUS network. The address is assigned during

field bus planning. The address section is from 2 to 123. The field bus master

(partner controller) is usually assigned the address 0 or 1.

Number of I points

Number of control signals to be processed via the PROFIBUS interface. Value

range 16 to 512 input signals (2 to 64 bytes)

Number of O points

Number of control signals to be processed via the PROFIBUS interface. Value

range 16 to 512 output signals (2 to 64 bytes)

Receive data

Memory location for receiving the ID code, max. 198 bytes at 2 bytes for I points

Send data

Memory location for sending results, max. 198 bytes at 2 bytes for O points

Receive IL data

Memory location for receiving IL data, max. 198 bytes at 2 bytes for I points

These data are processed using the IL function block ControlFieldbus.

Send IL data

Memory location for sending of IL data, max. 198 bytes at 2 bytes for O points

These data are processed using the IL function block ControlFieldbus.

Example

If 16I was selected as the number of I points and 32O as the number of O points, 16 inputs (= 2 bytes)

and 32 outputs (= 4 bytes) will also be available in the field bus configurator.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...