3 608 878 300

Tightening Technology |

Bosch Rexroth AG 103

System 350

| 3 608 878 300/2019-03

4.3.4

Performance level (PL) within the Rexroth Tightening System 350

The basis of this section is that every machine manufacturer is obliged to identify possible dangers this

machine might pose for the operator and to remove the risk related to the danger. In situations in which

the danger cannot be removed, every machine manufacturer is obliged to reduce this danger to the

largest possible extent. The danger can be reduced by:

•

Safety functions of the machine in the sense of intrinsically safe construction

•

Protective equipment

•

Instructions for the user

Since the Machinery Directive 2006/42/EC came into effect on December 29, 2009, machine

manufacturers are obliged to make a quantitative statement regarding the probability of a dangerous

failure of the safety functions and/or the safety equipment of their machine. For the

Rexroth Tightening

System 350

, these characteristics have been determined by an independent, accredited organization.

Risk assessment

In the risk evaluation of a machine, the later is first of all dismantled into its partial functionalities. For each

partial functionality, the risk emanating from this partial functionality for the user is then analyzed

separately. In order to be able to design a safety function or safety equipment for a specific dangerous

situation, you first of all have to determine the contribution to the risk reduction that has to be made by

the protective equipment.

This contribution can be determined by applying the standard

DIN EN ISO 13849-1:2008 Safety of

machinery – Safety-related parts of control systems"

.

The contribution to the risk reduction depends on

•

The severity of the injury to be expected,

•

The frequency with which the user is exposed to the danger,

•

And the possibility to recognize an imminent danger in due time.

It is indicated as discrete level specifying the ability of safety-related parts of a control system to perform

a safety function under foreseeable conditions, the so-called Performance Level (PL). Here, the

performance level is divided into 5 levels "a" to "e", whereas the following applies:

•

PL = a

is the lowest level of requirements for the reliability of the safety function and/or the protective

equipment of the machine.

•

PL = e

is the highest level of requirements on the reliability of the safety function and/or the protective

equipment of the machine.

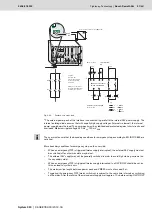

Functional safety in the Rexroth Tightening System 350

Depending on the machine design, the tightening spindle must - with tightening system - stop safely under

certain conditions and must not restart unexpectedly. This cannot be ensured by a tightening controller

consisting of hardware and software. (by definition of the machinery directive, industrial control systems

are generally not classified as safe. Exceptions are special safety control systems referred to as safety

PLCs.)

In order to still be able to guarantee safe stop and safe protection against unexpected restart, the

Rexroth

Tightening System 350

features a default emergency OFF interface. This interface is a safety function

within the

Rexroth Tightening System350

for which the probability of a dangerous failure has been

determined according to DIN EN ISO 13849-1.

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...