3 608 878 300

Tightening Technology |

Bosch Rexroth AG 503

System 350

| 3 608 878 300/2019-03

These characteristics are generated per activated docu buffer (if monitoring functions are available), see

Tightening results from several steps of a tightening process

. The torque threshold actual

value is not represented by a characteristic - however, it is included in the graph data.

Graphs

Currently, only angle/torque graphs are transmitted (the QDA protocol does not support other graph

types or more than one Y axis).

The transmission of the graphs can be configured for each tightening position. Via the parameter

graph

filter ,

the following options can be selected:

•

No graph transmission for the tightening position (

no graph

)

•

Graph transmission only for OK or only for NOK tightening processes (

only OK graph

or

only NOK

graph

)

•

Always graph transmission (

OK and NOK graph

)

In the tightening program itself (in the start step), the desired graph length (in points) can be defined. A

maximum of 2000 graph points can be set. If the tightening process generates more graph points, the

oldest may be removed.

K fields

6.13.2

Settings in the BS350 operating system

QDA protocol is configured via the BS350 operating system.

The configuration window can be opened in two different ways. This depends on the question whether

the BS350 is connected to a tightening system ("online") or not ("offline"):

•

Online:

System

QDA configuration

If no configuration file is stored on the tightening controller, a message is output and the configuration

window is not opened:

•

Offline:

File

New

QDA configuration

The configuration window is divided as follows:

•

Configuration of the target server, see

•

Definition of path information and ID codes, see

•

Configuration of the tightening position definition, see

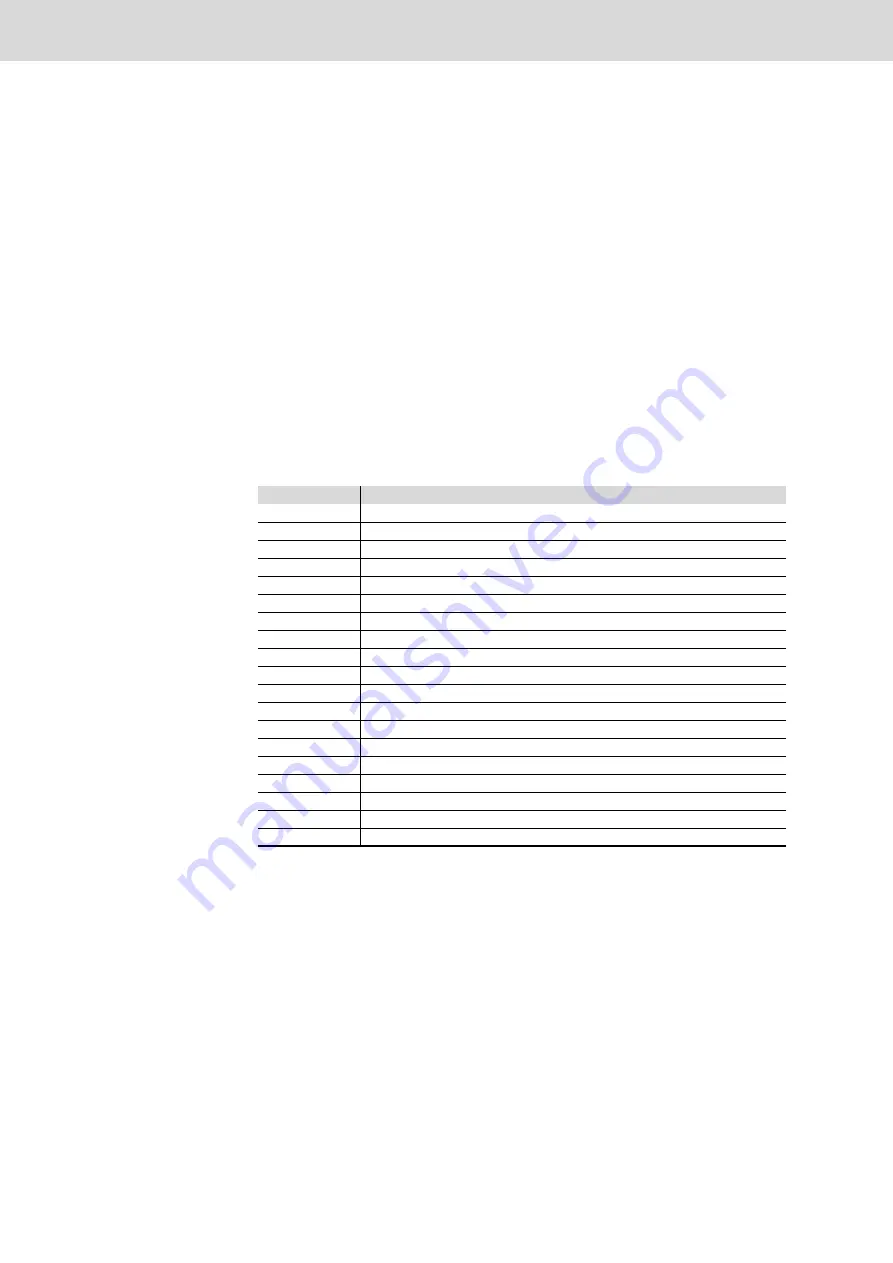

Table 6–182:

K fields

K field

Description

K0001

Measurement

K0002

Status (0 = available, 255, empty)

K0004

Date/time

K0100

Selection of the transmission type:

K0014

ID code

K0055

Number of repeated attempts

K0056

Results status: OK/NOK

K0057

Quality code text

K1001

Part number (ID/config)

K1002

Test plan (config)

K1086

OP/AVO (config)

K1201

Location name (with "-", max. 40 characters)

K1202

Hardware identifier (serno/spindle ID)

K2001

Characteristic number (serial no.)

K2002

Characteristic name (tightening position name + characteristic identification)

K2003

Characteristic identifier (channel/prg/step...)

K2009/K2022

Units/decimal places

K2101-K2121

Limits, values & type

K2142

Characteristic type

Summary of Contents for Rexroth Tightening System 350

Page 4: ...4 641 Bosch Rexroth AG Schraubtechnik System 350 3 608 878 300 2019 03 ...

Page 120: ...120 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 194: ...194 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...

Page 638: ...638 641 Bosch Rexroth AG Tightening Technology 3 608 878 300 System 350 3 608 878 300 2019 03 ...