Hydraulics training system WS290 | RE 00225-B/12.15

Bosch Rexroth AG 69/104

Set-up, installation and commissioning

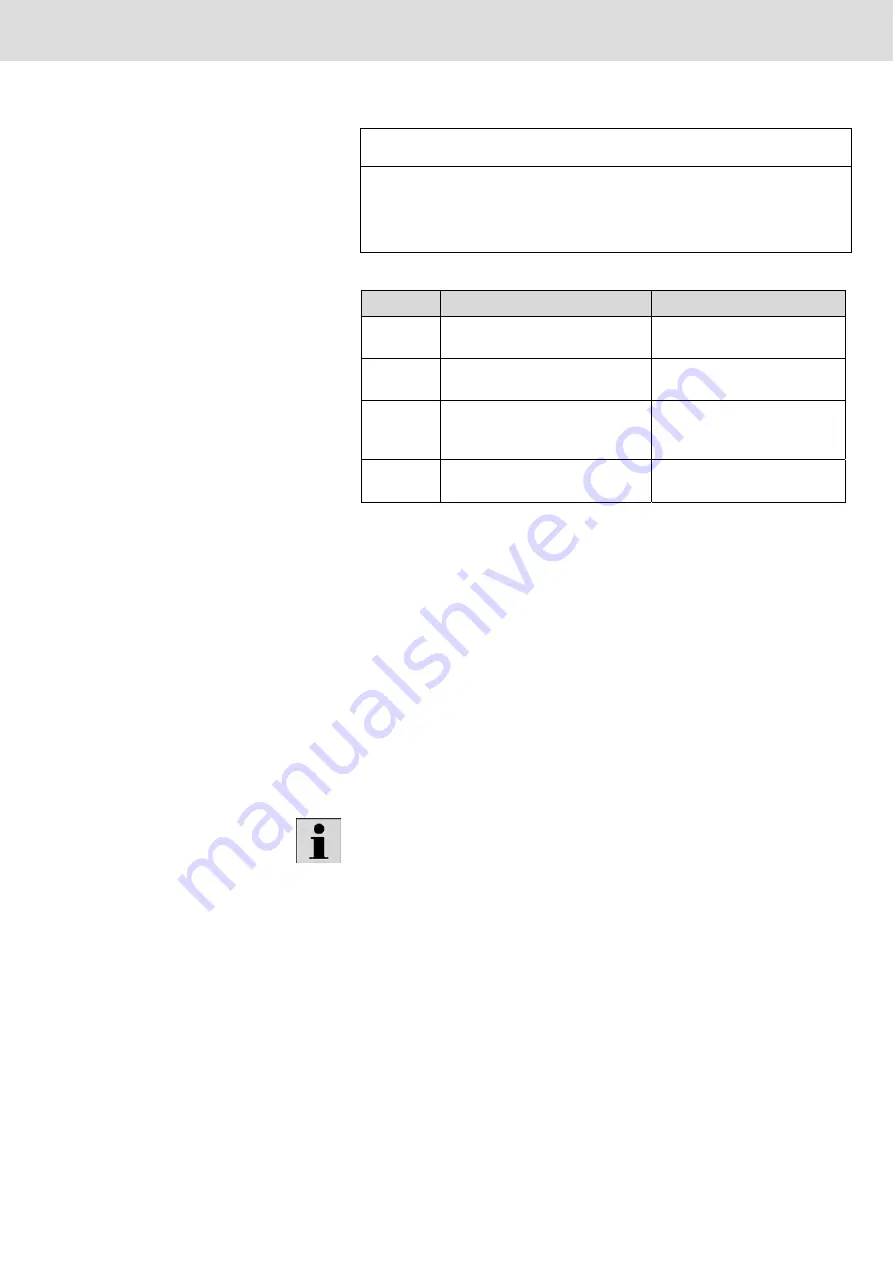

Table 9:

Possible errors and measures

No.

Possible causes

Remedy

1

Hydraulic fluid missing in the oil tank Fill hydraulic fluid into the

oil tank.

2

Leaky system

Check the system for leakage

and seal it

3

Pump defect

Stop the pump

Inform the Bosch Rexroth

service (pump exchange)

4

3-way ball valve not in

operating position

Bring the ball valve in

operating position

Operate the "OFF" switch at the power unit after 10 seconds at the latest.

9.5.4

Testing the hydraulic fluid condition

The pump circulation test at the measuring glass was successful. The closed

pump circuit as set-up in section 9.5.3 is maintained.

Close the shut-off cock at the measuring glass.

Operate the "ON" switch at the power unit.

Approx. 3 seconds after start-up of the pump, hydraulic fluid must flow into the

measuring glass.

Only fill approximately half of the measuring glass.

Immediately operate the "OFF" switch at the power unit.

Particularly with cold oil, the measuring glass may overflow as the pump

delivers more oil than it can flow back into the oil tank via the hose (5).

Carry out a visual inspection of the hydraulic fluid in the measuring glass:

–

The oil should be free from bubbles,

–

The color should be like amber and clear.

NOTICE

Danger of the hydraulic pump running dry!

Damage to property!

Stop the system immediately and check the possible causes.

In case of a defect, inform the Bosch Rexroth service.

Prerequisites:

How the test is carried out: