Hydraulics training system WS290 | RE 00225-B/12.15

Bosch Rexroth AG 85/104

Maintenance works

13.2

Maintenance schedule

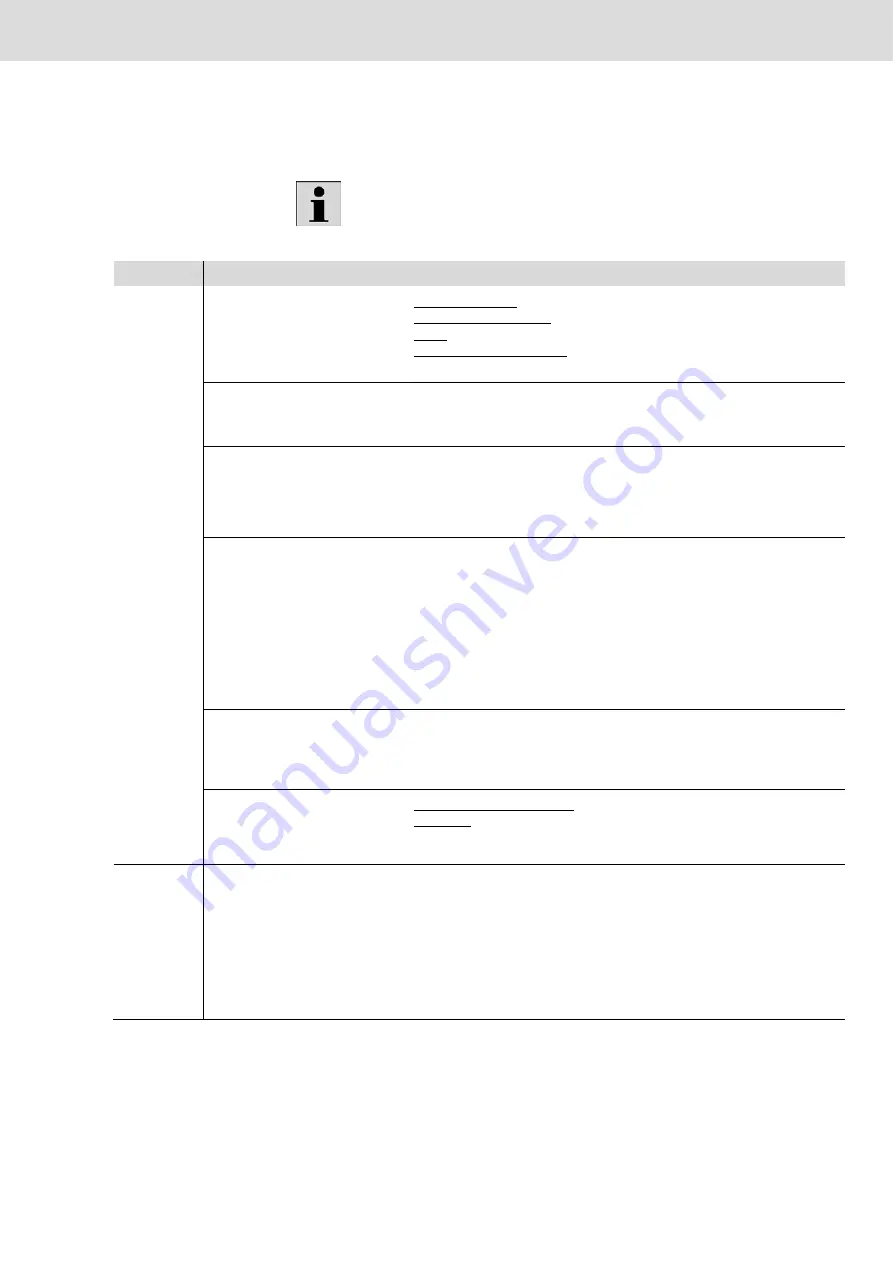

In the table below, the works are arranged, initially by maintenance interval

and then by assemblies/parts. The intervals have to be complied with.

Table 12:

Maintenance schedule for WS290 training system

When?

What?

Where?

Comments

Daily/prior to

any use

EMERGENCY OFF pushbutton

Check the function.

Effects when pressing the

button

No start-up when interlocked

In the event of a malfunction:

Stop the system

Inform specialized electrician

Oil tank

Check filling level:

Above MIN?

Below MAX?

In case of low filling level:

Refill hydraulic fluid up to the MAX marking

Oil grade: According to DIN 51519 HLP VG22

Oil tank in the measuring glass

Check condition of the hydraulic

fluid:

No turbidity?

No black coloring?

No acid smell?

Exchange hydraulic fluid in case of:

Turbidity, black coloring, acid smell

Return flow filter

Check filter contamination:

Color sector of the pressure

gauge display green/yellow/red.

In case the display is in the YELLOW range:

Exchange filter element

Clean oil

In case the display is in the RED range:

Exchange filter element

Exchange the oil

When exchanging filters, only use original

spare parts!

Fittings

Check for externally visible

damage:

Breaks on pressure gauges?

At protective screws?

Have them replaced immediately

in case of damage!

Inform the Bosch Rexroth service.

Hydraulic power unit

Running smoothness of motor

and pump:

Noises?

Vibrations?

In case of irregularities:

Inform the Bosch Rexroth service.

Hydraulic lines, hydraulic hoses

Check all lines, hoses and

fittings for leakage and

externally visible damage!

Hydraulic hoses must be

immediately exchanged, if:

The exterior is damaged (abrasive points,

cuts, cracks, embrittlement).

They are deformed in the pressurized or

depressurized condition, if the hydraulic

hose lines do not have their natural forms.

Leakages.