Bosch Rexroth AG

VCH 05.1

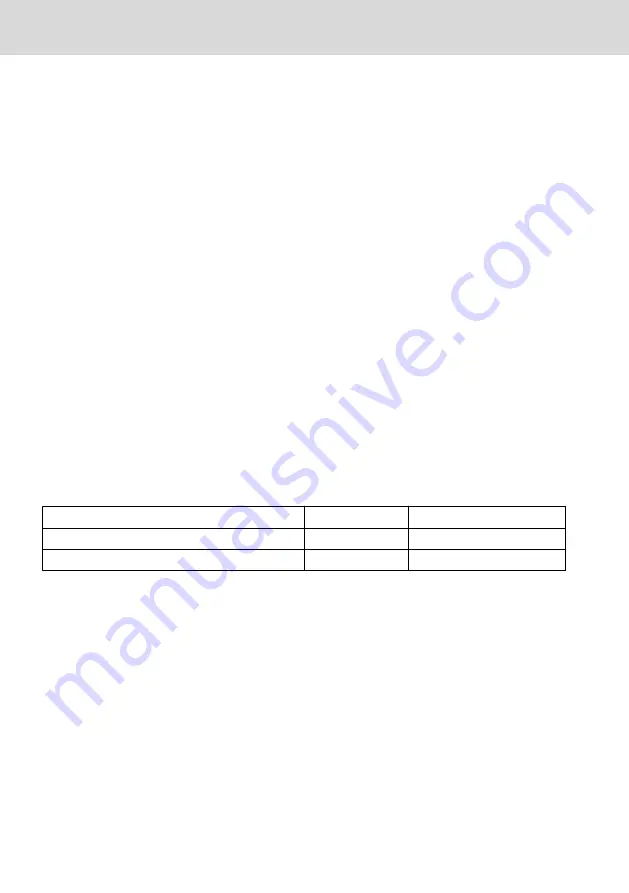

Record of Revision

Edition

Release Date

Notes

First edition

04.2013

--

Edition 02

04.2014

Revision

Copyright

© Bosch Rexroth AG 2014

This document, as well as the data, specifications and other information set

forth in it, are the exclusive property of Bosch Rexroth AG. It may not be repro-

duced or given to third parties without its consent.

Liability

The specified data is intended for product description purposes only and shall

not be deemed to be a guaranteed characteristic unless expressly stipulated in

the contract. All rights are reserved with respect to the content of this docu-

mentation and the availability of the product.

Editorial Department

Development Automation Systems EH (KaWa/PiGe)

RS-0dd51e5d937fa7980a6846a5019d1794-2-en-US-4