Maintenance | Start Line TCE 420 | 45

en

1 695 108 074

2016-07-27

|

Robert Bosch GmbH

9. Maintenance

9.1

Warning

!

Non-professional personnel should not perform

maintenance.

!

Before performing any maintenance, you should

switch off the air supply and power. By repeatedly

depressing the pedal, you can release the residual

air in the machine completely.

!

Perform maintenance periodically as described in

this operating manual. This is necessary to prolong

the life of the TCE 420 and guarantee normal

operating conditions.

!

If maintenance is not performed periodically, the

reliability and proper operation of the TCE 420

are no longer guaranteed, and the TCE 420 can

be damaged. Operators and persons nearby can be

injured.

!

Defective parts must be replaced with original parts

provided by the manufacturer.

!

Removing or breaking safety devices such as the

safety valve and standard nozzles violate the safety

standards.

!

You should not modify components on the machine

without authorization.

i

Special note: The manufacture will not honor claims

arising from the use of parts provided by other

suppliers and for damage caused by removing or

breaking the safety devices.

¶

Keep the working area clean.

¶

Do not use compressed air to remove dirt from the

TCE 420.

¶

Keep generation of dust in the area to a minimum.

9.2

Maintenance operations

9.2.1

Maintenance unit and bead breaking cylinder

!

Perform \the following operation at least once every

30 days.

1.

Check the oil level in the oil cup. If there is not

enough oil, remove the oil cup and replenish the

lubrication oil as shown in following figure. The oil

filled into the lubricator must be the special SAE 20

oil.

2.

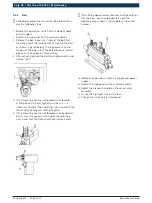

Oil feeding speed regulation: Move the bead

breaking cylinder back and forward to check

whether the oil feeding speed is one drop of oil per

2 stokes of the cylinder. If not, use the bolt B to

adjust as shown in following figure.

3.

Drainage: Check the water quantity in the water cup.

Turn/press the valve at the low end of the water cup

to drain.

4.

Before operating, always run the bead breaking

cylinder back and forward while observing the

lubricator to make sure it starts feeding oil to the air

passage. After you confirm that the lubricator works

normal, you can guarantee each part of the air route

system under

perfect lubrication

.

5.

Periodically tighten the nut at the fixed equipment.

6.

Periodically fill in the lubrication oil components can

move and slide to each other.