14.

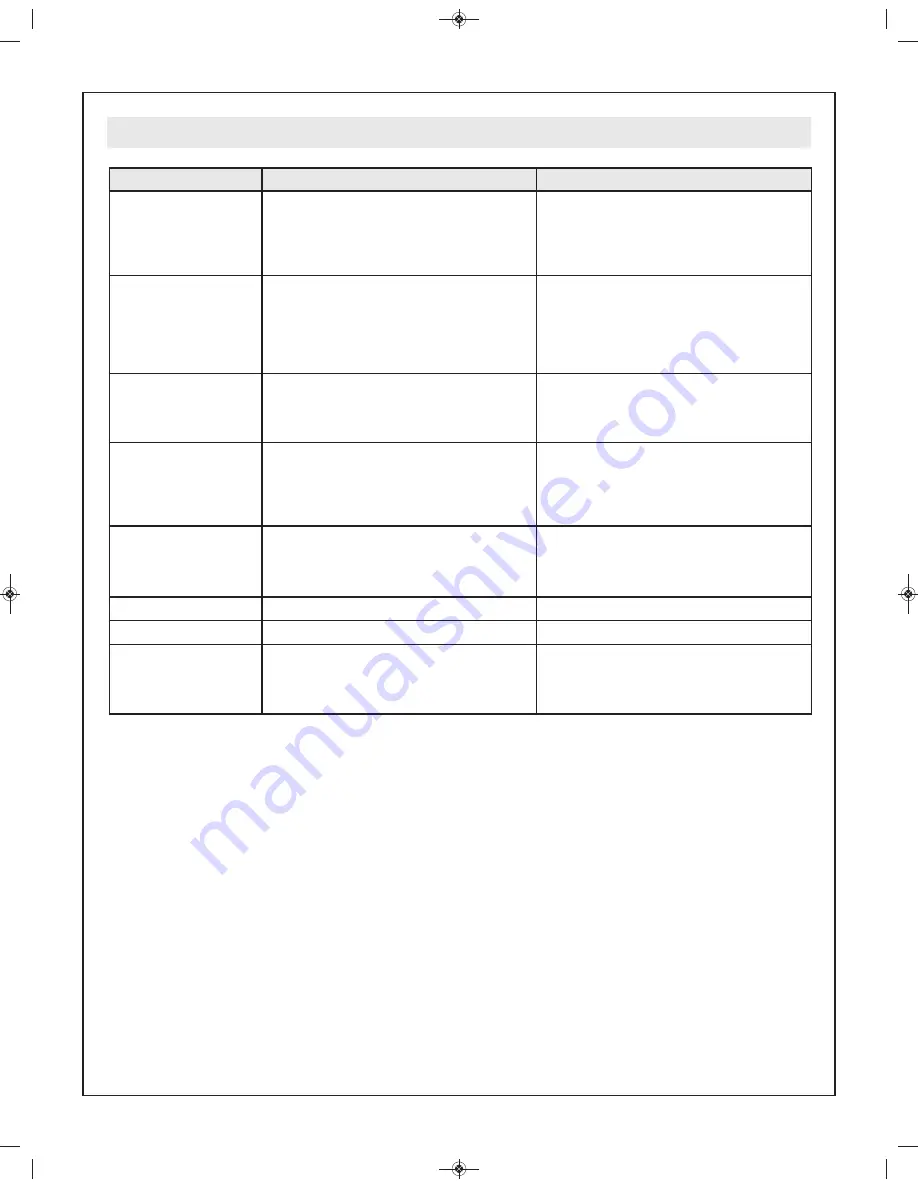

Troubleshooting

PROBLEM

SYMPTOMS

RESOLUTION

Tool operates, but no

staple is driven.

• Check for a jam.

• Check function of follower.

• Follower springs weakened or damaged?

• Check for proper staples.

• Verify tool is loaded.

• Clear a jam.

• Clean and lubricate.

• Replace follower spring.

• Use only recommended staples.

• Reload tool.

Staple driving action

seems slow or weak.

• Check air pressure is in operational range.

• Driver blade worn?

• Piston O-ring worn or damaged?

• Bumper worn?

• Check recommend hose diameter and length.

• Increase air pressure (Do not exceed 120 psi).

• Use pneumatic tool lubricant.

• Contact BOSCH for replacement or repair.

• Replace Bumper.

• Follow recommendations.

• Check hose for kinks.

Tool drives staples too

deep.

• Check air pressure.

• Check Depth of Drive.

• Check bumper wear.

• Reduce air pressure. Min. Operational

pressure 60 psi.

• Use “Depth of Drive Adjustment”.

• Replace bumper.

Tool drives staples too

shallow.

• Check air pressure.

• Check Depth of Drive.

• Check recommend hose diameter and length.

• Increase air pressure. Max. Operational

pressure 120 psi.

• Use “Depth of Drive Adjustment”.

• Follow recommendations.

• Check hose for kinks.

Tool skips staples or has

intermittent feed.

• Check for proper staples.

• Check function of magazine per page 7.

• Follower spring weakened or damaged?

• Piston O-ring cut or heavily worn?

• Use only recommended staples.

• Clean and lubricate.

• Replace follower spring.

• Contact BOSCH for replacement.

Staples jam frequently.

• Check for proper staples.

• Use only recommended.

Driven staples are bent.

• Driver blade worn?

• Contact BOSCH for replacement.

Staples driven properly

during normal operation,

but does not drive fully at

faster nailing speeds.

• Check inside diameter of air hose.

• Check suitability of compressor.

• Use correct air hose.

• Use correctly sized compressor for number of

tools used and work rate.

BM 2610957389 04-09:BM STN150-18 06-09 6/17/09 7:45 AM Page 14