Page 2

© 2011 Bosch Security Systems, Inc.

DS970 Series Installation Instructions

•

Remove the circuit board from the base. Loosen the Vertical

Adjust Screw and slide the circuit board down, then out.

•

Break away the appropriate thin-wall wire entrance and mounting

hole coverings in the base.

•

Using the base as a template and aligning it so that the detector

will be mounted with the terminal block at the top and the PIR

lens at the bottom, mark the location of the mounting holes on

the mounting surface. Pre-start the mounting screws.

•

Route wiring as necessary. Route to the rear of the base and

through the wire entrance.

Make sure all wiring is unpowered

before routing.

•

Securely attach the base to the mounting surface.

•

Return the circuit board to the base and tighten the Vertical Adjust

Screw.

4.0

Wiring

CAUTION

Only apply power after all connections have been

made and inspected. Do not coil excess wiring inside

detector.

NOTE:

Input power must use only an Approved Limited Power

Source. Alarm and Tamper Contacts to be connected to a

SELV (Safety Extra-Low Voltage) circuit only.

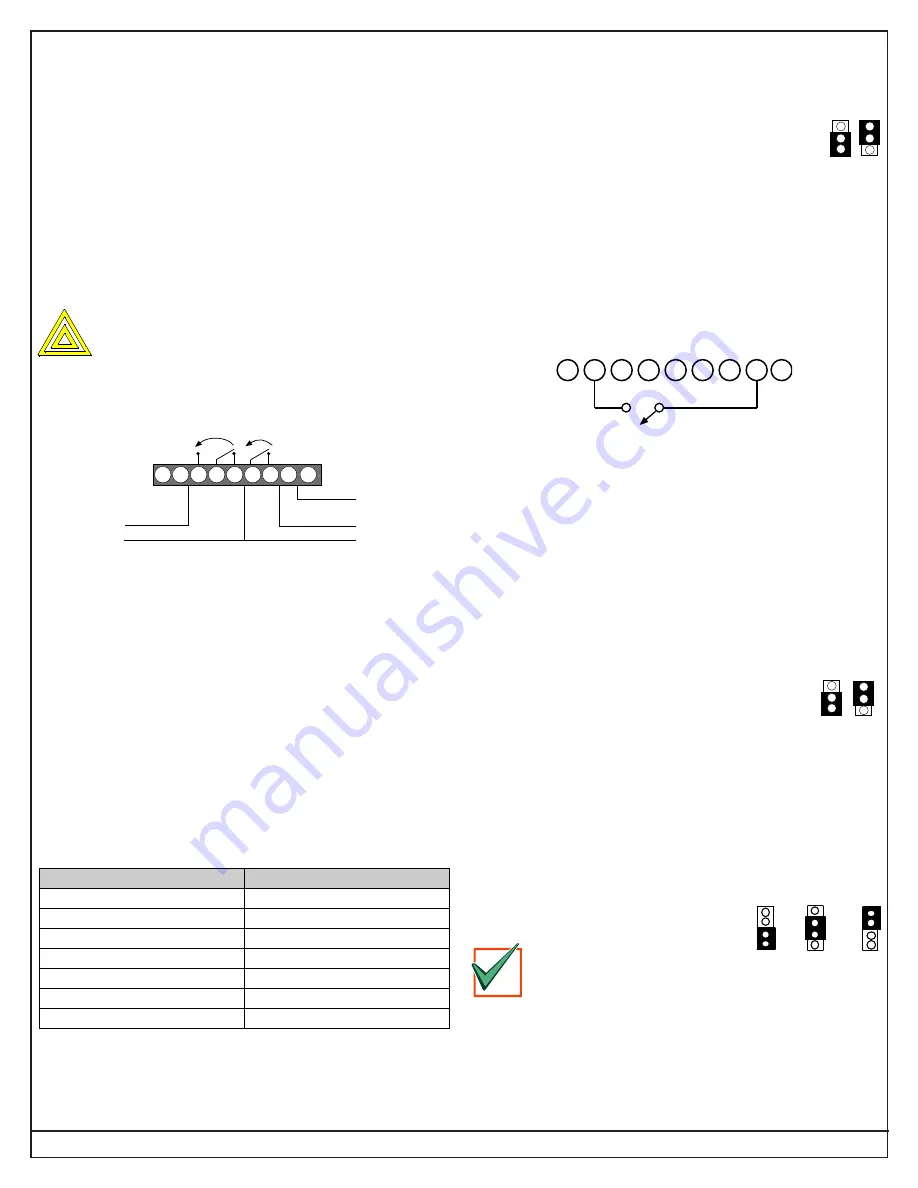

– + NO C NC T T M

9-15 VDC

Input

Alarm Relay

Tamper

Memory

Input

TR Trouble

Alarm

1 2 3 4 5 6 7 8 9

•

Terminals 1 (–) & 2 (+):

Voltage limits are 9 to 15 VDC. Use no

smaller than #22 AWG (0.8 mm) wire pair between the detector

and the power source.

•

Terminals 3, 4, & 5

: Alarm relay (reed) contacts rated 3 watts,

125 mA, 28 VDC maximum for DC resistive loads and protected

by a 4.7 ohm, ½ watt resistor in the common "C" leg of the relay.

Use Terminals 4 & 5 for Normally Closed circuits.

NOTE:

Do not use with capacitive or inductive loads.

•

Terminals 6 & 7:

Tamper contacts rated at 28 VDC, 125 mA.

•

Terminal 8

: Memory. Refer to Section 6.0 Feature Selection.

•

Terminal 9

: Trouble. Solid State output.

NOTE:

Plug the wire entrance hole with the foam plug provided

after all wiring connections have been made.

5.0

LED Operation

The detector uses a tri-color LED to indicate the various alarm and

supervision trouble conditions that may exist. See chart below.

LED

CAUSE

Steady red

Unit alarm

Steady yellow

Microwave activation (walk test)

Steady green

PIR activation (walk test)

Flashing red

Warm-up period after power-up

Flashing red (2 pulse sequence)

Motion monitor time-out

Flashing red (3 pulse sequence)

Anti-mask detection

Flashing red (4 pulse sequence)

MW or PIR self-test failure

Flashing red 2 - 4 = The LED flashes 2-4 times a cycle.

NOTE:

During walk testing, the LED will light for the first technology

(microwave or PIR) and then light red to indicate a detector

alarm. The LED will not indicate activation of the second

technology by lighting its color.

6.0

Feature Selection

6.1

LED On/Off Pins

The ON position allows operation of the tri-color LED. If

LED indication is not desired after setup and walk tests

are completed, place in the OFF position. The OFF position does not

prevent the LED from indicating supervision trouble conditions.

6.2

Memory Operation and Microwave Inhibit

To use the alarm memory function, cut the Memory Jumper (after

walk testing). When this jumper is cut, the Microwave Inhibit function

is also activated. This eliminates microwave transmissions during

disarmed periods.

To supply voltage, connect a switch between Terminals 2 and 8 on

the detector’s T-strip as shown here:

1

2

3

4

5

6

7

8

9

Note

:

If switched voltage (between 9 and 15 V) is supplied from

another source, such as an alarm panel, then wiring must

also be provided from Terminal 1 of the detector to the

negative (-) side of the alternate source.

When voltage is applied to Terminal 8, any stored alarm is cleared

from memory and it is ready to store the next alarm.

When voltage is removed from Terminal 8 (disarmed condition), the

tri-color LED is enabled, and a stored alarm will cause the tri-color

LED to turn ON red continuously. If there is no stored alarm, the tri-

color LED and relay will respond to PIR only; they will activate only

during a present alarm.

NOTE:

The Motion Monitor and Anti-Mask pins must be in the OFF

position in order for the Microwave Inhibit

feature to work.

6.3

PIR Sensitivity Selection Pins

For selection, place the plug across the pins marked

STD for Standard or INT for Intermediate mode.

•

Standard Sensitivity:

The recommended setting for maximum

false alarm immunity. Tolerates environmental extremes on this

setting.

•

Intermediate Sensitivity:

The recommended setting for any

location where an intruder is expected to cover only a small portion

of the protected area. Tolerates normal environments on this

setting. This setting will improve your intruder catch performance.

6.4

Motion Monitor/Anti-Mask Pins

By enabling Motion Monitor and the Anti-Mask feature with the selection

pins, a choice of Off or 1 day or 30 days

may be chosen for Motion Monitor.

IMPORTANT

If 1-day Motion Monitor is

selected, the memory feature must be enabled by

cutting the memory jumper. The Motion monitor timer

will be suspended when the detector is in night (armed)

mode.

On

Off

INT

STD

Off

30

1