Technical description

|

11

6 720 807 794 (2013/04)

UNIMAT

3.2.2

Function principle

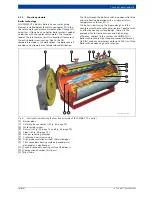

In the flue gas heat exchanger, heat is recovered from

the hotter boiler flue gas by channelling cooler mains

return water through the heat exchanger pipe to reduce

the flue gas temperature. The energy gained in this way

gives a higher boiler efficiency and therefore lower fuel

consumption and lower flue gas emissions.

With the fuels gas and low sulphur fuel oil, aim for as low

a water inlet temperature as possible at the flue gas heat

exchanger. This deliberately creates operation with

condensate (flue gas condensation), so that even higher

efficiency can be achieved.

If the flue gas heat exchanger is operated with fuel oil

(not low sulphur quality), ensure a corresponding

minimum water inlet temperature at the flue gas heat

exchanger of 60 °C to protect it from corrosion on the

flue gas side. With oil operation, an optional control on

the water side can be used to raise the water inlet

temperature at the flue gas heat exchanger to the

required minimum level by mixing in pre-heated water.

With oil operation, for flue gas heat exchangers with an

integral flue gas bypass, if the water inlet temperature

cannot be raised to the minimum level, the entire flue

gas flow from the boiler bypasses the flue gas heat

exchanger, using the flue gas control valve. A flue gas

temperature control unit is available as an option for an

additional charge.