46

|

Boiler control and control system

UNIMAT

6 720 807 794 (2013/04)

7.4

UNIMATIC display units and control units

With the standard equipment level of the UNIMATIC

display units and control units, the digital display shows

the flow, return or flue gas temperature with an accuracy

level of

±

2 K. LEDs indicate which temperature is

currently being shown. The measured values can be

passed on via three outputs for 4 to 20 mA. The keypad

enables temperature limits to be set. If a limit is

exceeded, the associated diode flashes and a signal is

issued to one of the three floating outputs. The control

unit with the standard equipment level (display module

A) is therefore an ideal supplement to the CFB control

units.

The B, C and D measuring and control modules also

enable constant control of the boiler. They can be used

instead of the CFB 810 control unit.

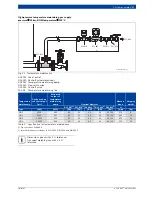

Fig. 28 UNIMATIC display units and control units for UT-

L boilers (dimensions in mm)

+

Available

–

Not available

7.5

BCO boiler control

The intuitive BCO boiler control based on a PLC offers

maximum operating data transparency for optimum

boiler operation and also provides comprehensive

control solutions for medium and large-scale systems.

The touchscreen display allows a wide range of

information such as operating conditions, operating

data and measured values to be displayed. It is easy to

connect to overriding visualisation and control systems

and is teleservice-ready.

Component

Type of instrument casing

A

B

C

D

Temperature indicator

+

+

+

+

Temperature monitor

–

+

+

+

Burner control (stages)

–

2

1)

1) Excess temperature protection for modulating burner

3

High limit safety cut-out

–

+

+

+

Temperature control unit

–

+

–

+

Stage II

–

+

–

+

Stage III

–

–

–

+

Table 25 Equipment level of the UNIMATIC display units

and control units

350

150

200

265

6 720 642 347-39.2il