Basic principles

|

5

6 720 807 794 (2013/04)

UNIMAT

surfaces. It means the heating surfaces can be viewed

from the water chamber.

•

Matching system technology

Numerous matching components are available for all

boilers, which enable optimisation of the entire

system.

2

Basic principles

2.1

Basic principles of condensing

technology

2.1.1

Net and gross calorific values

The net calorific value H

i

(formerly H

u

) specifies the

amount of heat that can be obtained from one cubic

metre of gas or one kilogram of fuel oil. With this

reference figure, the products of combustion are

present in a gaseous state.

Compared to the net calorific value H

i

, the gross calorific

value H

s

(formerly H

o

) also contains the condensation

heat from the water vapour as additional energy.

2.1.2

Boiler efficiency above 100 %

The condensing boiler or boiler with condensing heat

exchanger utilises not only the net calorific value H

i

in

order to produce heat, but also the gross calorific value

H

s

of a fuel.

For all efficiency calculations in German and European

standards, the net calorific value H

i

is always selected at

100 % as a reference figure, meaning that a boiler

efficiency of over 100 % can result. This is the only way

of comparing conventional boilers and condensing

boilers or boilers with condensing heat exchangers.

Boiler efficiency can be raised by up to 15 % in

comparison with conventional boilers. Compared with

older systems, it is even possible to save up to 40 %

energy.

When comparing the energy utilisation of conventional

boilers and condensing boilers or boilers with

condensing heat exchangers, an energy statement such

as the example shown in Fig. 3 can result.

Condensation heat (latent heat)

• The proportion of condensation heat in natural gas is

approx. 11 %, relative to the net calorific value H

i

.

With low-sulphur fuel oil, the proportion of

condensation heat is approx. 7 %, relative to the net

calorific value H

i

.

This heat is unused in conventional boilers.

• By making use of the condensation in the water

vapour, the condensing boiler or boiler with

condensing heat exchanger enables considerable

utilisation of this heat potential.

Flue loss (sensible heat)

• With the conventional boiler, the heat in the flue gas,

which is at a relatively high temperature of 150 °C to

210 °C, escapes. This means an unused heat

proportion of around 6 % to 9 % is lost.

• The dramatic reduction of the flue gas temperatures

in a condensing boiler or boiler with condensing heat

exchanger down to 30 °C makes use of the sensible

heat in the hot gas and considerably reduces the flue

loss.

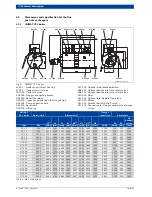

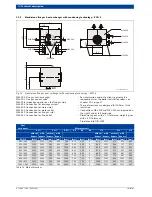

Energy statement comparing conventional boilers and

condensing boilers or boilers with condensing heat

exchangers

Fig. 3

Energy statement comparing conventional boilers

and condensing boilers or boilers with

condensing heat exchangers (example with

natural gas)

Conventional boiler

Condensing boiler or boiler with condensing

heat exchanger

η

K

Boiler efficiency

q

A

Flue losses (sensible heat)

q

L

Unused condensation heat (latent

heat)

q

S

Radiation losses

1)

Relative to net calorific value H

i

= 100 %

q

L

= 11 %

q

A

= 5,9 %

q

S

= 0,1 %

q

L

= 1,5 %

q

A

= 1 %

q

S

= 0,5 %

6 720 642 347-75.1il

η

K

= 94 %

111 %

1)

111 %

1)

η

K

= 108 %