58

|

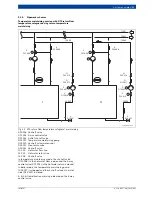

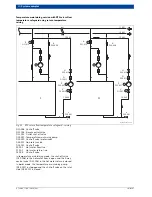

System examples

UNIMAT

6 720 807 794 (2013/04)

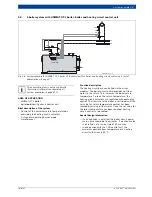

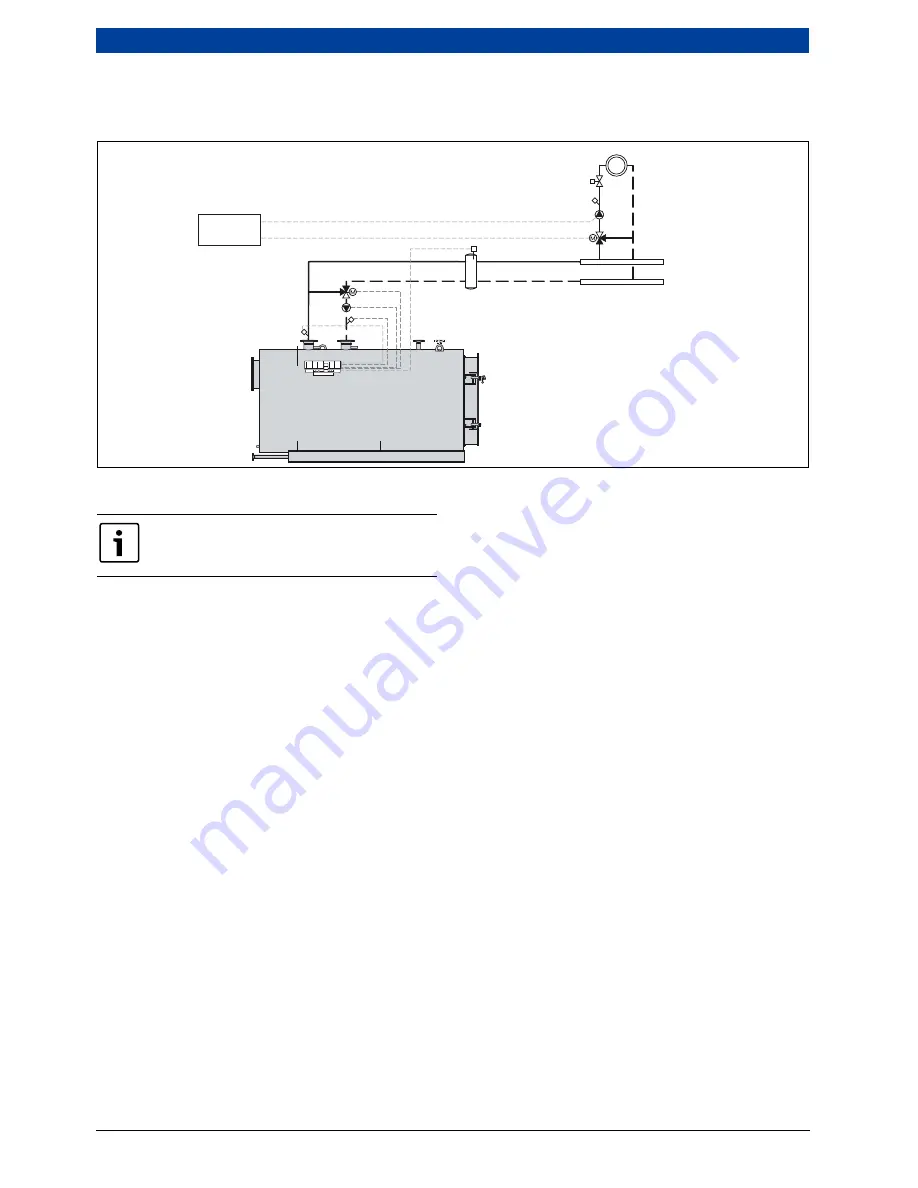

9.5

1-boiler system with UNIMAT UT-Lboiler: boiler and heating circuit control unit with hydraulic

separation

Fig. 39 System example with boiler and heating circuit control unit and hydraulic separation (list of abbreviations

page 47)

AREA OF APPLICATION

• UNIMAT UT-L boiler

• boiler

and

heating circuit control unit

• Hydraulic separation

• System structure in this form if a feed pump is

required, e.g. through sizing the heating circuit

pumps, or if several distributor stations are required,

or if the distributor stations are installed far apart

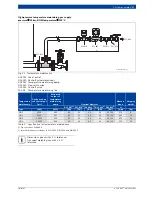

Brief description of the system

• Minimum return temperature controlled via a

separate actuator in the boiler circuit and a boiler

circuit pump

• 2-stage or modulating burner mode

• Automatic or weather-compensated load limitation

• Control of heating circuit using CFB control unit

Function description

The 3-way valve is actuated to control the return

temperature. The return temperature sensor measures

the boiler return temperature. If this falls below the set

value, the flow rate to the heating return is constantly

restricted by actuating the 3-way valve. If the return

temperature rises above the set value, the 3-way valve is

reopened and the flow rate to the heating circuit

increases.

Special design information

• Size the boiler circuit pump for the maximum

calculated flow rate and the pressure loss in the

boiler circuit. Switch it to constant mode or set a run-

on time of 60 minutes.

• Allow for a low loss header or a distributor with

bypass and non-return valve.

• In conjunction with the CFB control unit, the

maximum possible flow temperature of a heating

circuit with mixer is 90 °C.

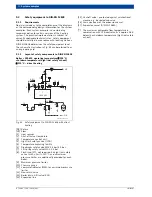

HK

SH

PH

FV

THV

WH

6 720 803 977-19.1itl

CFB 930

+ CMC 930

+ CMM 920

DDC / GLT

RK

FZ

FVS

VK

PK

SR

FK

The circuit diagram is only a schematic

illustration! Information regarding all

system examples

page 47 ff.