System examples

|

59

6 720 807 794 (2013/04)

UNIMAT

9.6

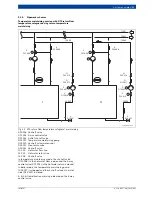

1-boiler system with UNIMAT UT-L boiler: boiler circuit control unit

Fig. 40 System example with boiler circuit control unit (list of abbreviations

page 47)

[

1)

] Enabling (potential-free)

Burner stage I

Burner stage II or modulation

AREA OF APPLICATION

• UNIMAT UT-L boiler

• boiler circuit control unit

– Maintaining the operating conditions

– Enabling of burner stages

Brief description of the system

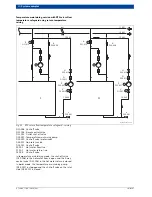

• Minimum return temperature controlled via a

separate actuator in the boiler circuit and a boiler

circuit pump as shunt pump

• 2-stage or modulating burner mode

• Control of heating circuit using CFB control unit or on-

site control unit

Function description

To control the return temperature, the 3-way valve is

actuated, as is the boiler circuit pump which is installed

in the bypass line to the boiler. The return temperature

sensor measures the boiler return temperature. If this

falls below the set value, the flow rate to the return is

constantly restricted and the bypass from the heating

return to the heating flow is opened. The heating circuit

flow rate remains almost constant even during this

operating phase. The boiler circuit pump safeguards the

optimum flow rate in the boiler circuit.

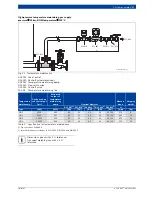

Special design information

• If a check valve is installed, the boiler circuit pump

run-on time should be five minutes. If no check valve

is installed, set a run-on time of 60 minutes.

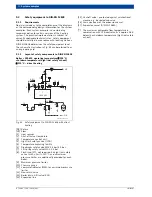

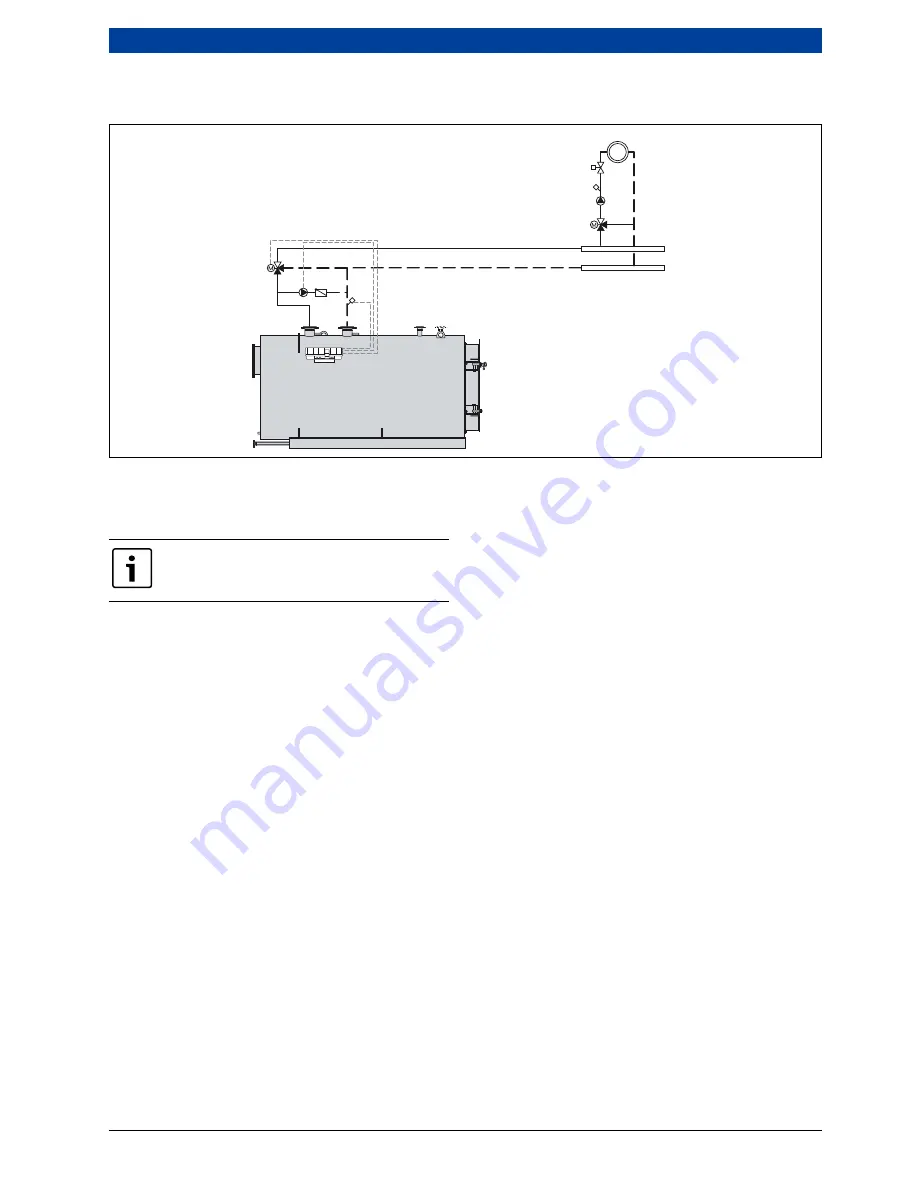

VK

RK

FZ

HK

KR

PK

SH

PH

FV

THV

VV

VR

SR

6 720 803 977-20.1itl

CFB 810

+ CME 930

The circuit diagram is only a schematic

illustration! Information regarding all

system examples

page 47 ff.